Automatic opening and closing pressure-relief anti-explosion safety valve for pipeline system

A technology of automatic opening and closing, pipeline system, applied in the direction of safety valve, pipeline system, balance valve, etc., can solve the problems of inaccurate return, large guiding resistance, intensified explosion venting force, etc., to achieve accurate automatic opening and closing, reduce The effect of guiding resistance and fast pressure relief

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to further illustrate the above-mentioned purpose, technical scheme and effect of the present invention, the present invention will be described below in conjunction with the accompanying drawings and relevant known technical knowledge through the embodiments:

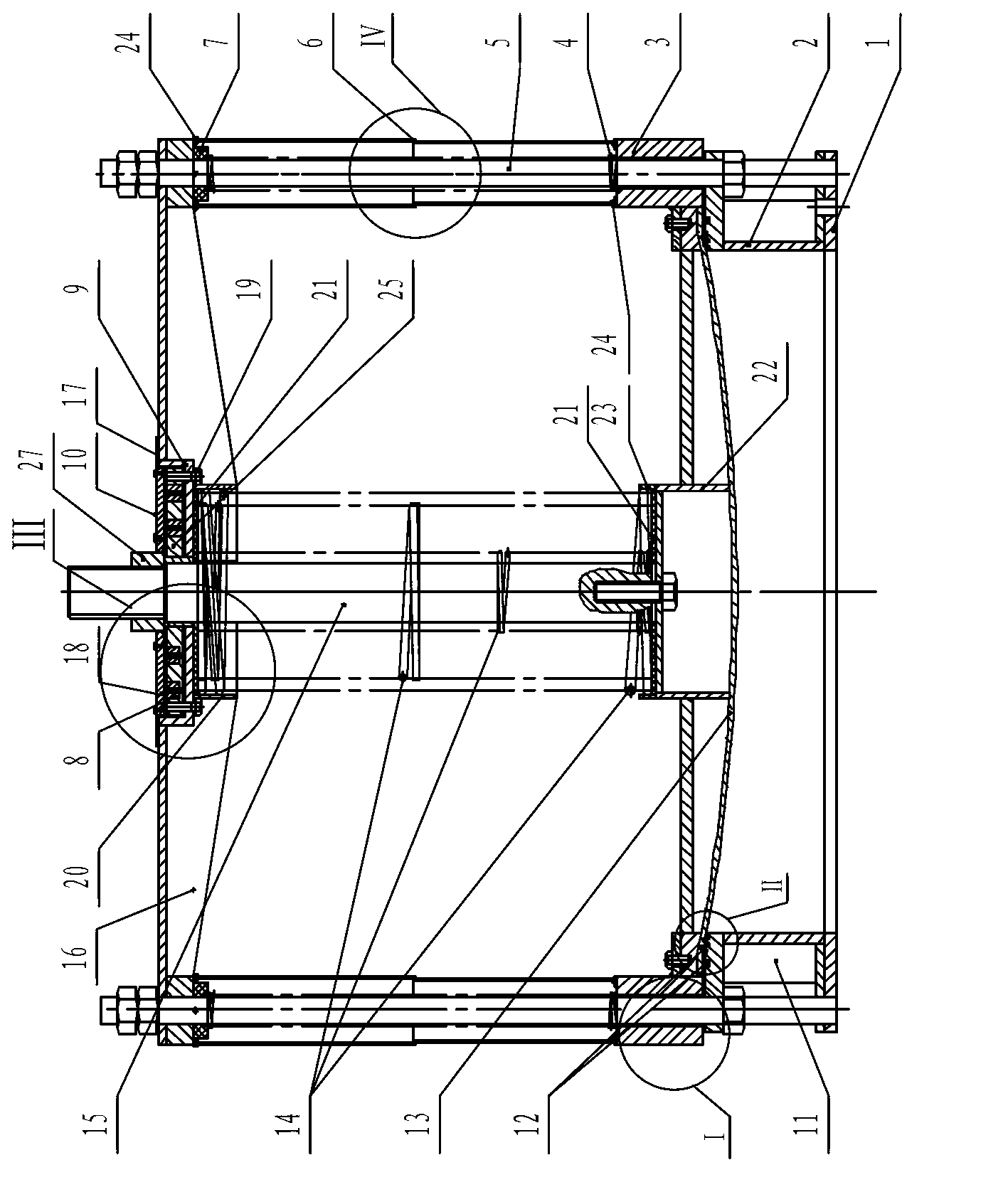

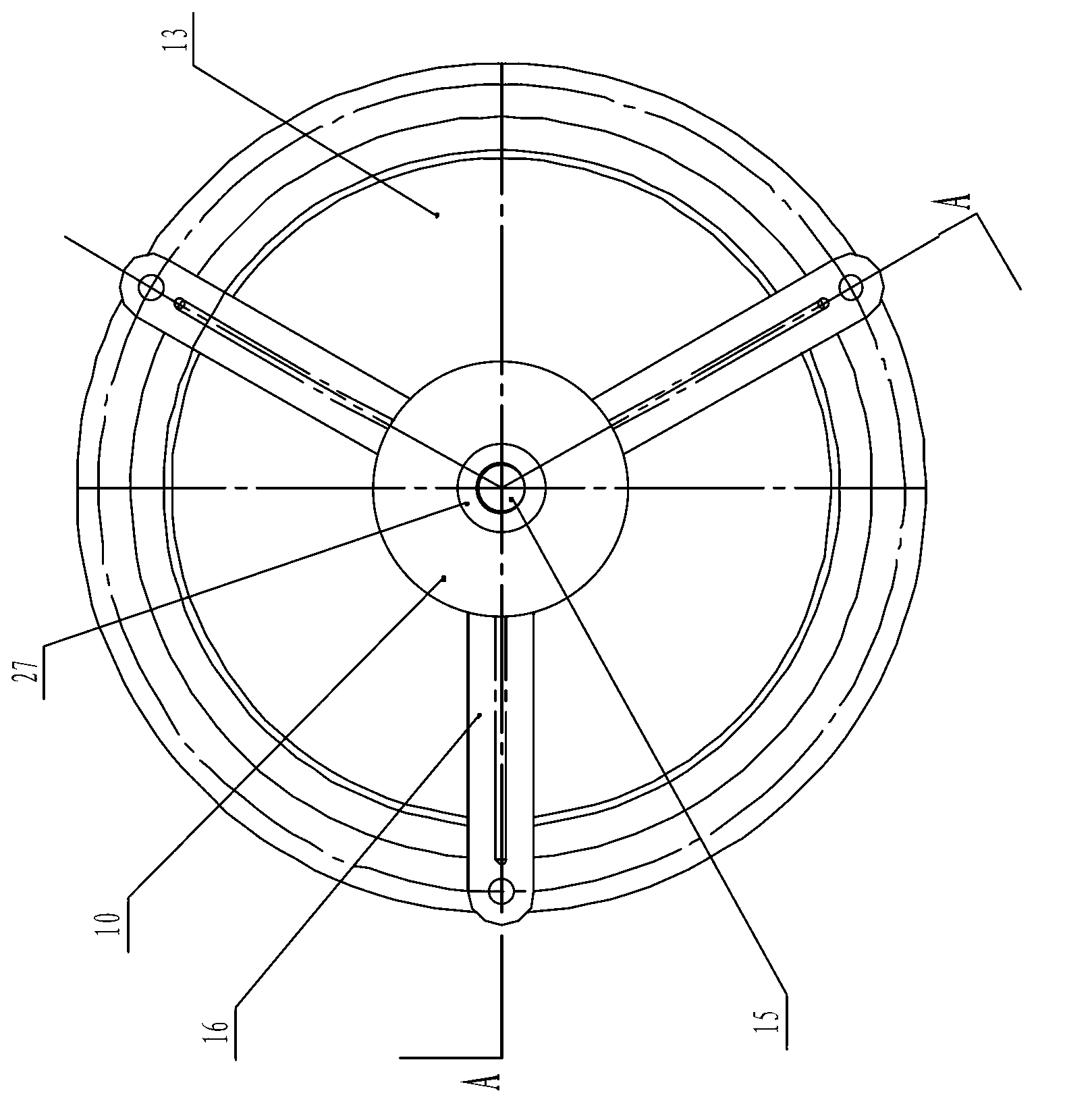

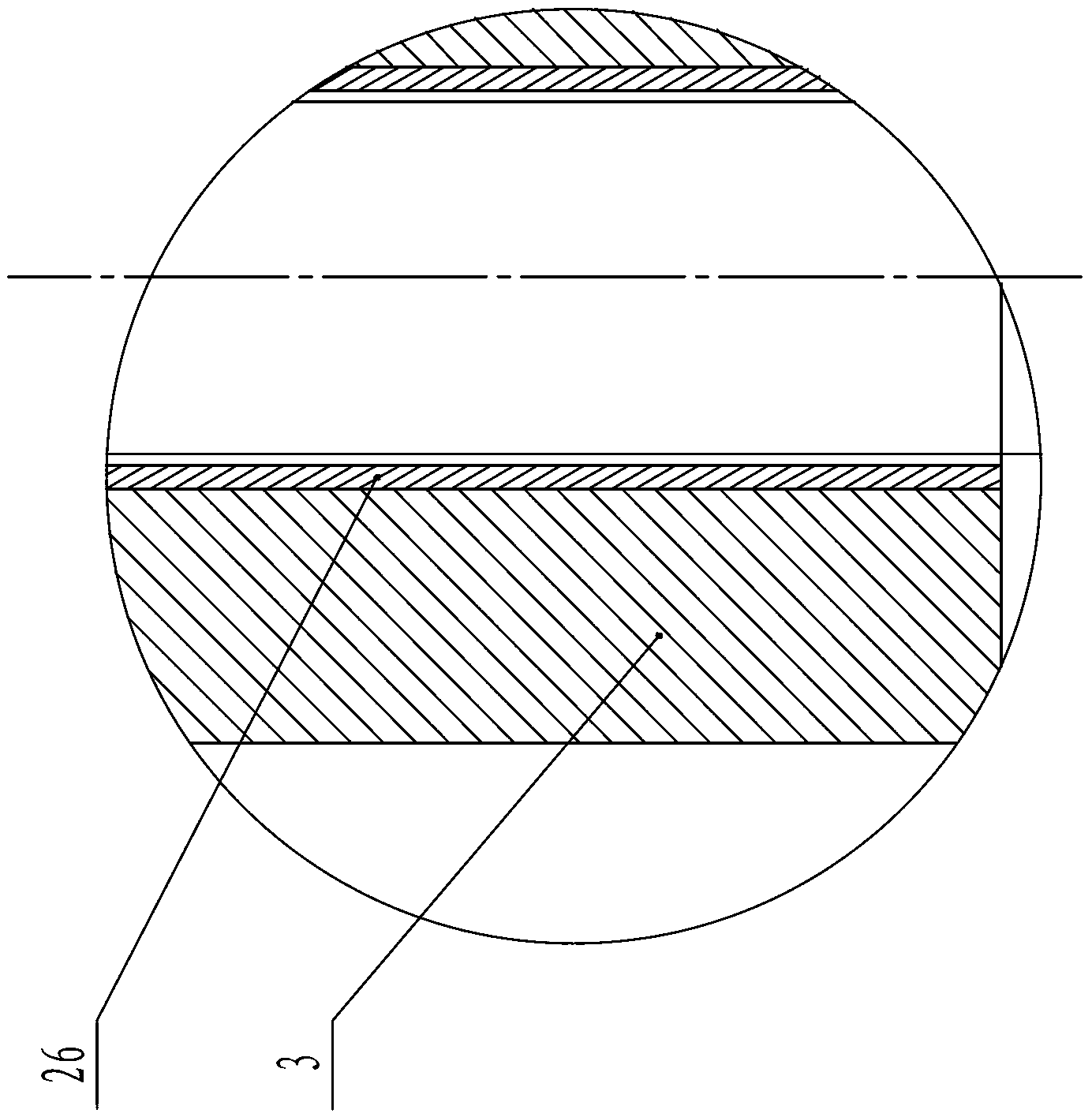

[0030] A pipeline system automatic opening and closing pressure relief explosion-proof safety valve, such as Figure 1-6As shown, the valve includes a valve body seat 2, a guide rod 5, an auxiliary return spring 4, a leading rod 15, an adjustable magnetic disk 9, a suction cup 18, and a bracket 16; There are flanges, and there are cooling fins 11 on the outer periphery of the seat between the two flanges. The flange below the valve body seat 2 is equipped with a butt flange 1, and the flanges on the upper and lower sides of the valve body seat 2 and On the butt joint flange 1, there are three guide rod holes evenly distributed on the circumference, and a seal groove is arranged on the upper flange of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com