Patents

Literature

53results about How to "Fast pressure relief" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

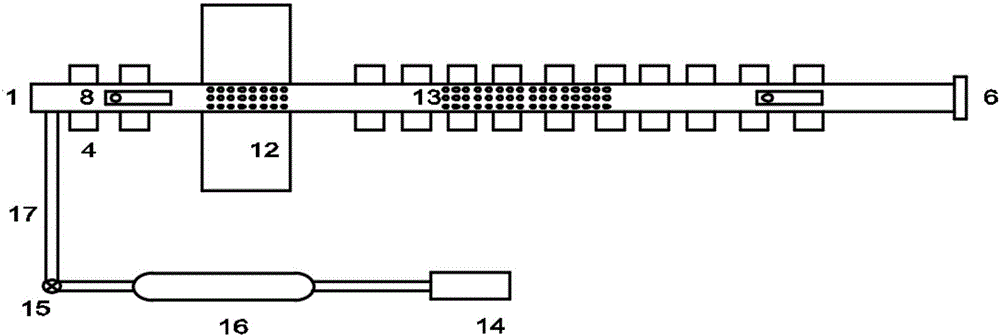

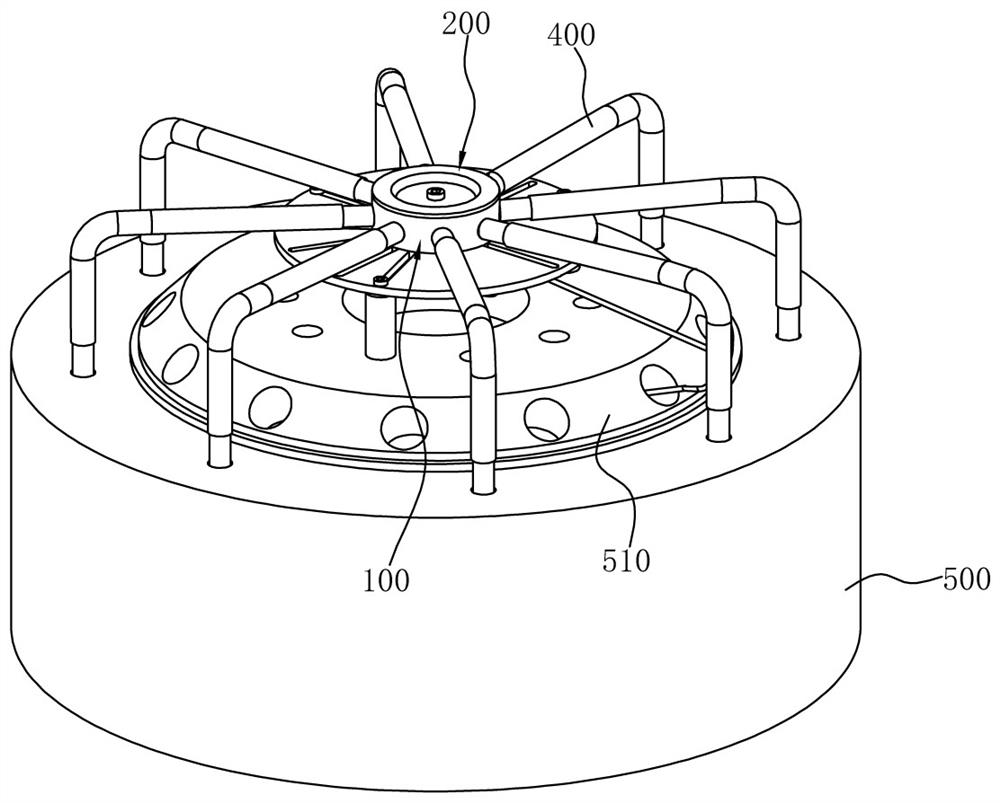

Emission and recovery integrated air cannon experiment apparatus

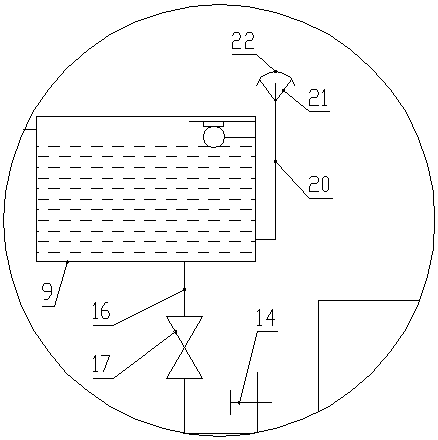

InactiveCN105758442AThe principle is simpleFew partsMeasurement devicesSolenoid valveDecompression chamber

The invention provides an emission-recovery integrated air cannon experiment apparatus. The air cannon experiment apparatus triggers a bullet by using air expansion to do work so as to better simulate the overload environment when the bullet is blasted, which can truly reflect the overload condition of the bullet. The air cannon experiment apparatus is mainly composed of an air cannon barrel, an annular precompressed chamber, an air cannon bracing frame, a measuring bulkhead, a decompression valve gun port, a spring decompression chamber, a test engine, a fastener, a slide rail, a clamping ring, a rupture of membranes sheet, a pressure relief aperture, a solenoid valve and an air cushion cover. A certain amount of air is fed into an air cylinder by using an air compressor, and at the same time the test engine is locked by using the fastener. When pressure inside an auxiliary segment is sufficiently enough to overcome a fastening force, the test engine is launched, and the air cannon is accelerated, evenly decelerated, and even stopped, so as to achieve soft recovery by using air. The apparatus of the invention is characterized by few movable members, simple and reliable structure, easy mounting and dismantling, and rapid decompression.

Owner:NANJING UNIV OF SCI & TECH

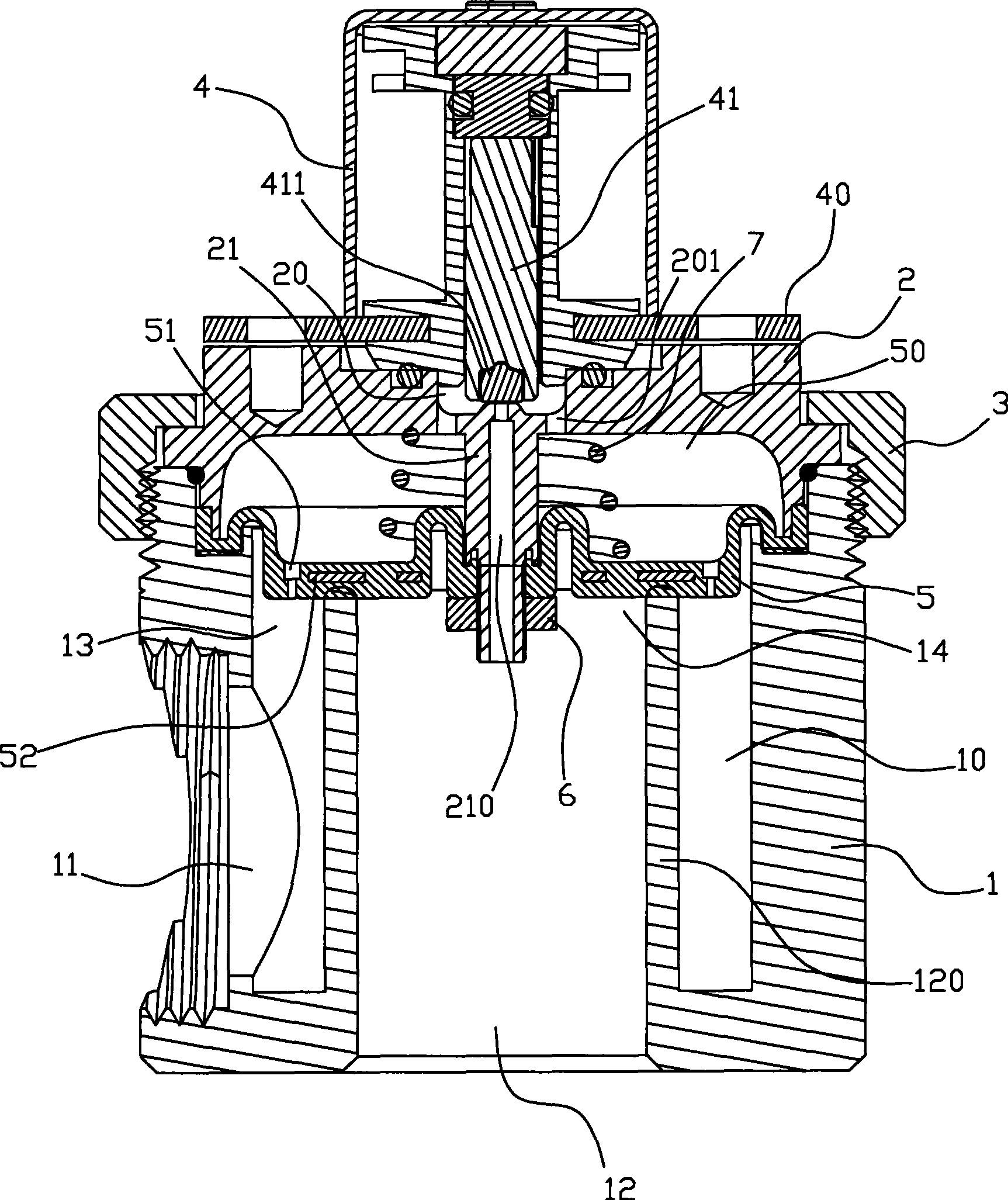

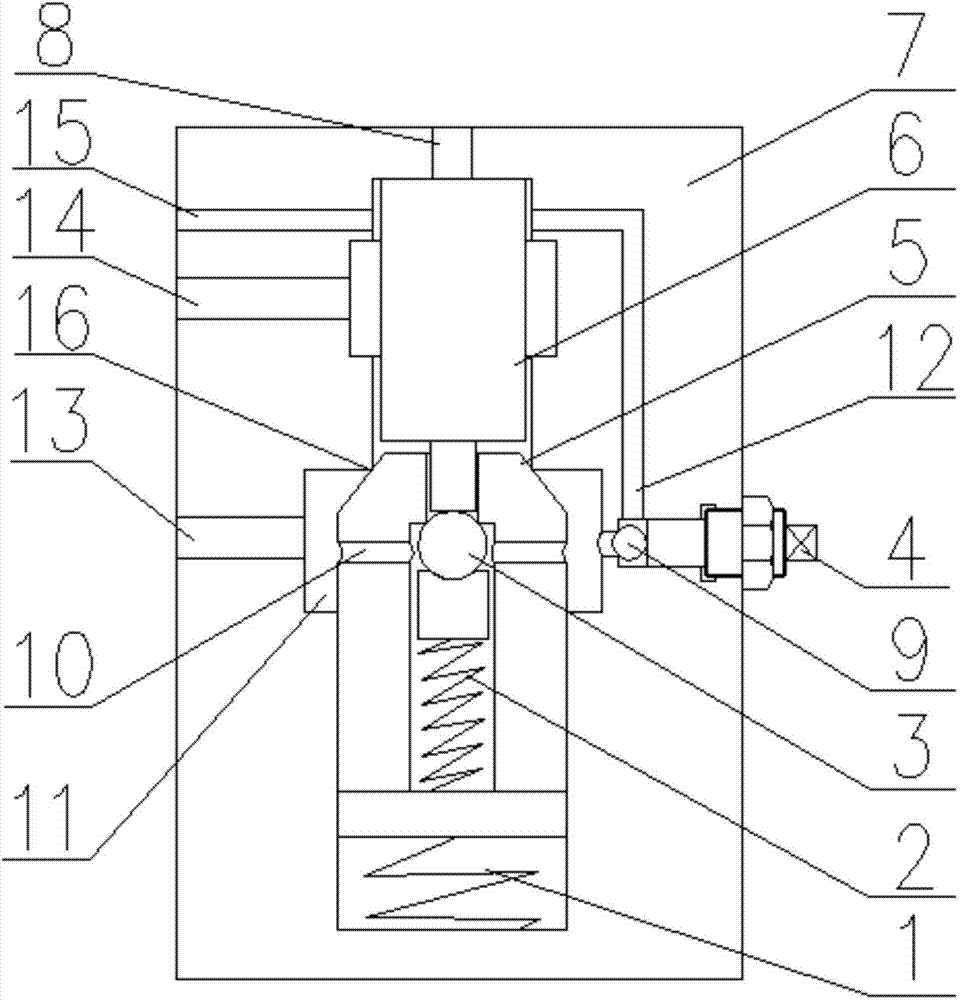

Electromagnetic pilot-operated diaphragm valve

InactiveCN101446357AFast pressure reliefAccelerateDiaphragm valvesEngine diaphragmsJet flowElectromagnetic valve

Owner:朱振连

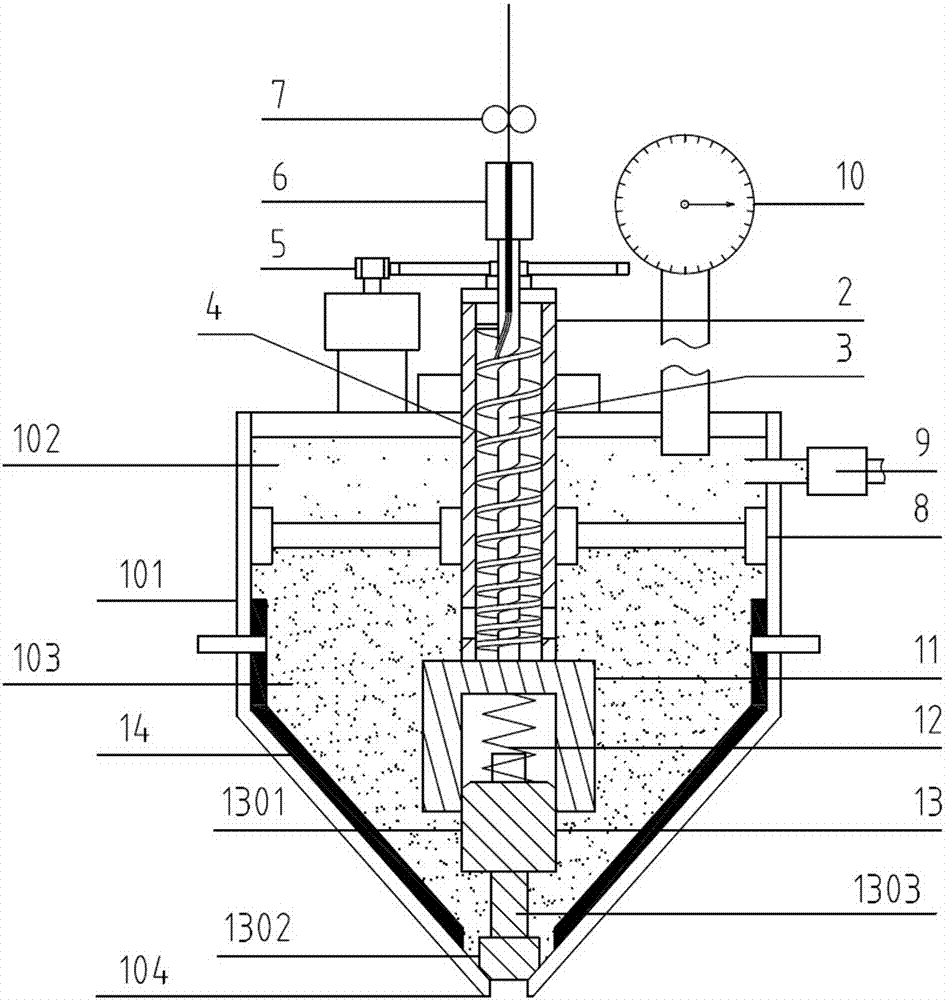

Dual-piston pressure-controlling type material steam explosion method and devices

InactiveCN102059076ASolve stressSolve highPressurized chemical processGrain treatmentsThermodynamicsVALVE PORT

The invention discloses a dual-piston pressure-controlling type material steam explosion method comprising the following steps of: feeding materials into a tank body from a feed opening of the tank body; steaming towards the tank body at the rear part of the closed feed opening; when the materials are heated to the steam explosion temperature, pushing a boosting piston in the tank body to compress the materials to allow the tank body to boost to the steam explosion pressure; and quickly releasing pressure to enable the materials to expand and burst and discharging the materials. The invention discloses a steam explosion device comprising the tank body, wherein a boosting piston and a pressure-relief piston are arranged in the tank body; the feed opening, a steam inlet and a discharging port are arranged on the tank body between the initial positions of the boosting piston and the pressure-relief piston; a valve is arranged on the steam inlet; The invention also discloses an another steam explosion device comprising a tank body, wherein a boosting piston and a pressure-relief piston are arranged in the tank body; a feed opening and a discharge opening are arranged on the tank body between the initial positions of the boosting piston and the pressure-relief piston; a heating jacket is arranged on the tank body between the feed opening and the discharge opening and is provided with a heating medium inlet and a heating medium outlet; and valves are respectively arranged on the heating medium inlet and the heating medium outlet.

Owner:SOUTHEAST UNIV

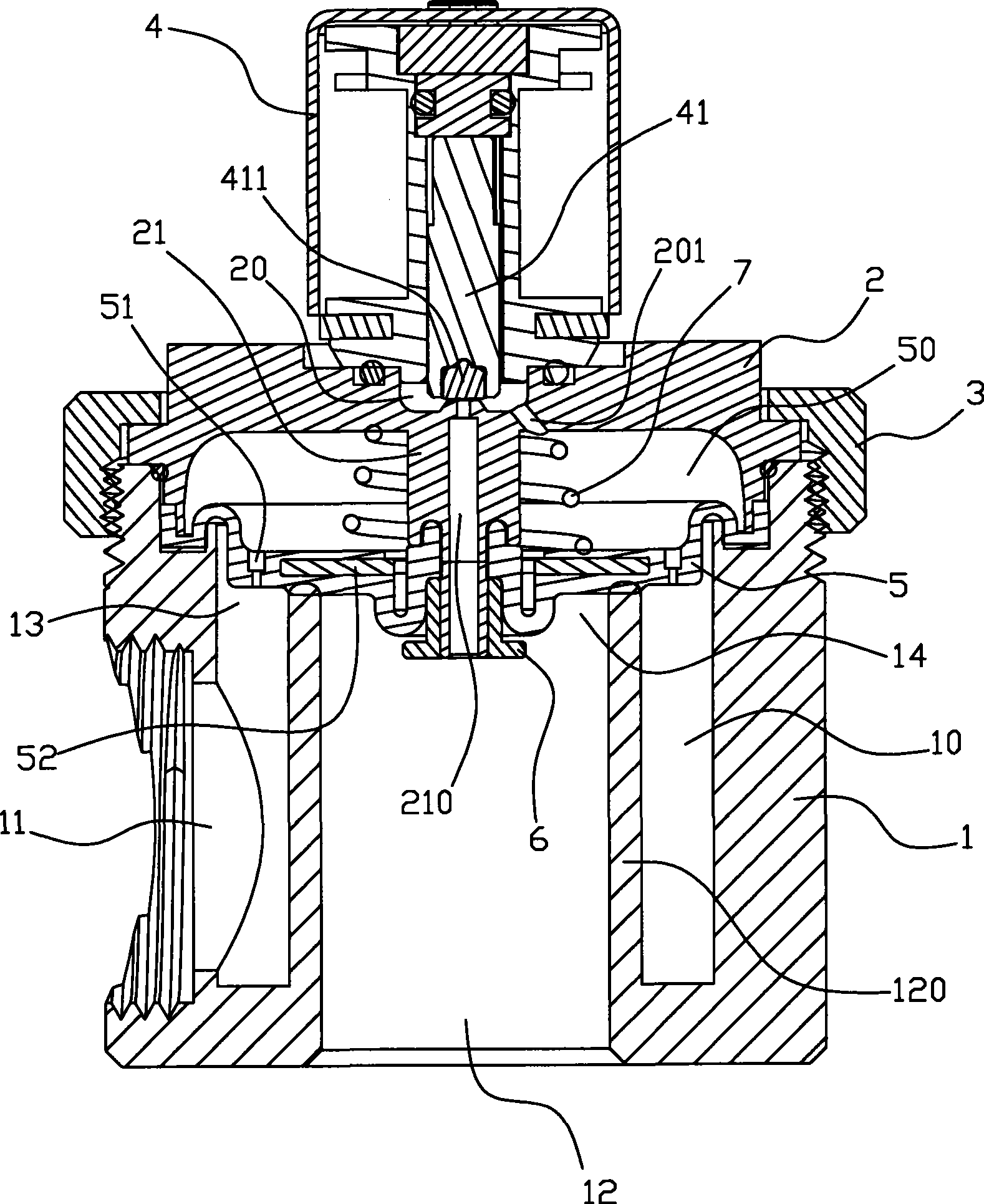

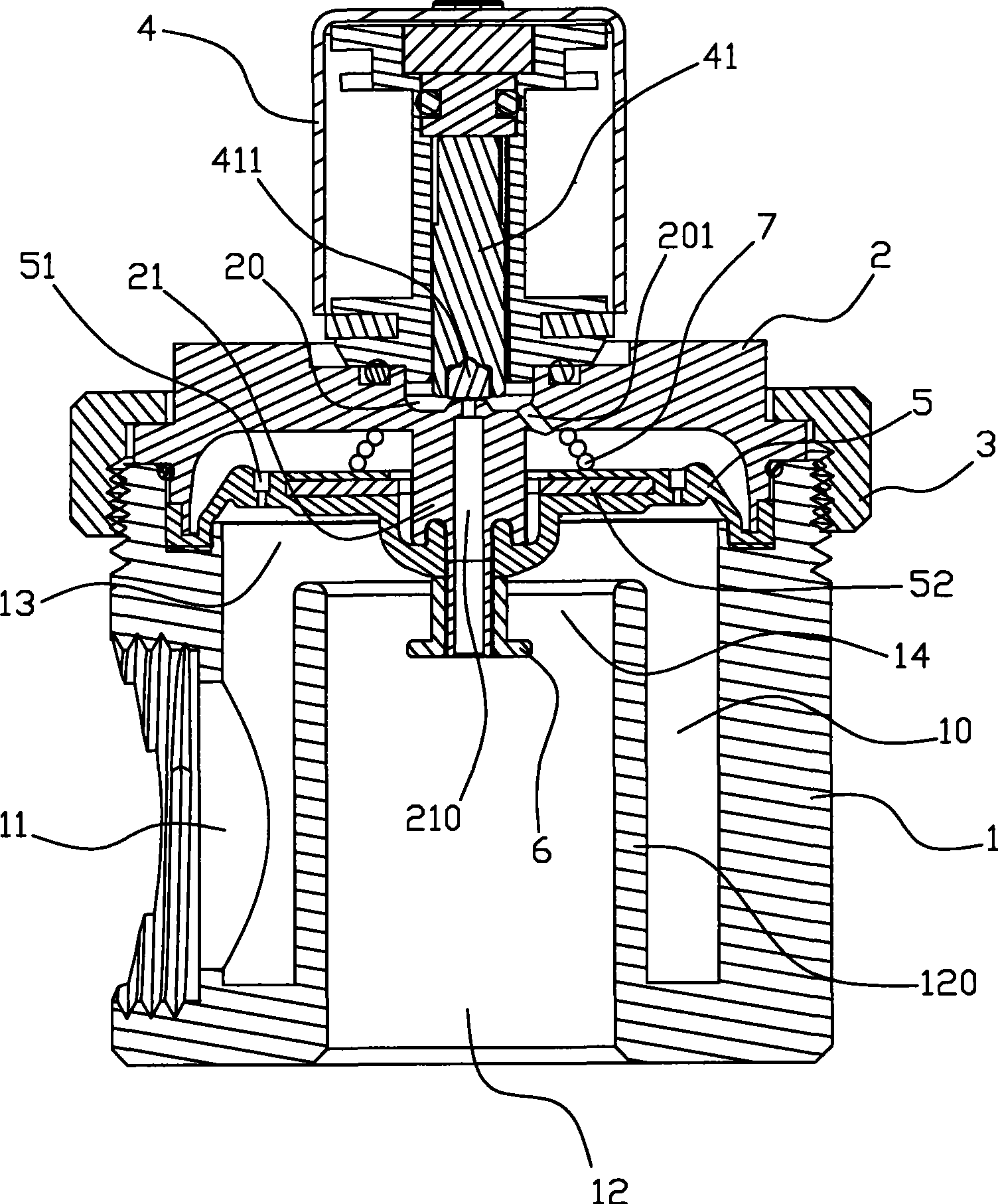

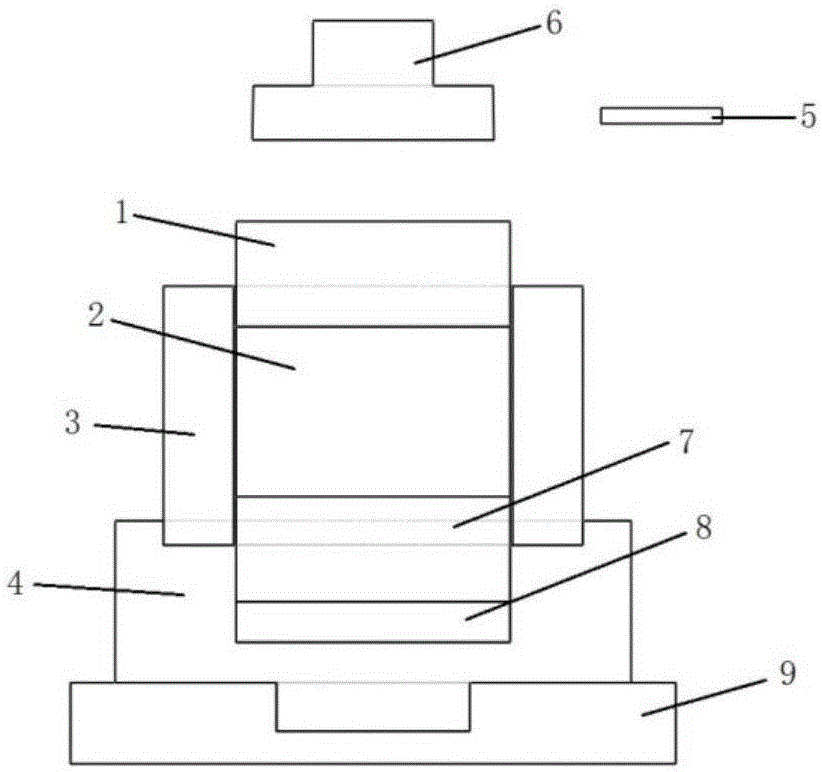

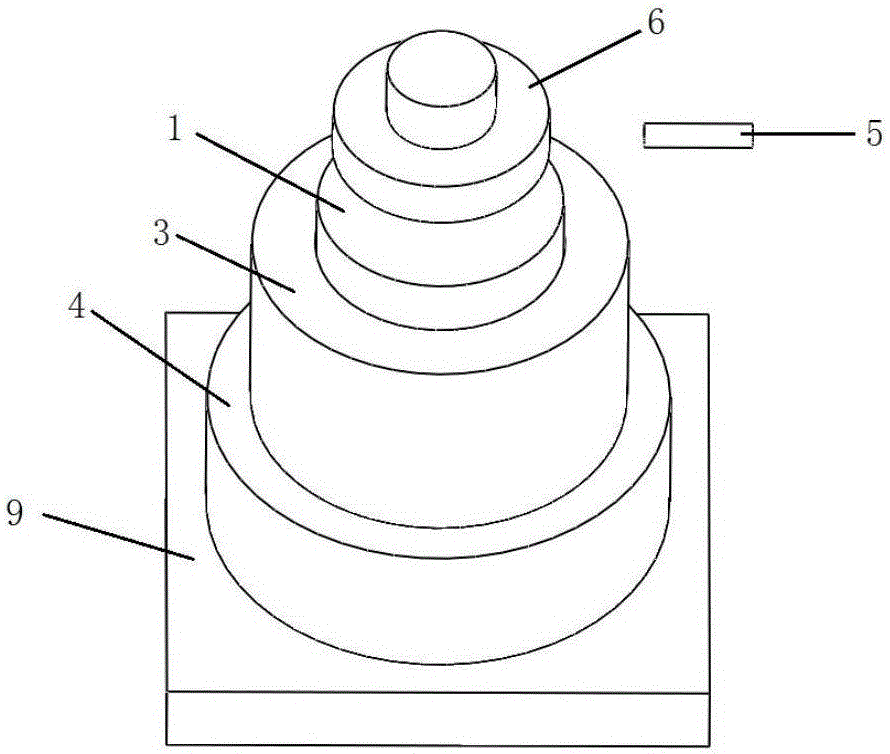

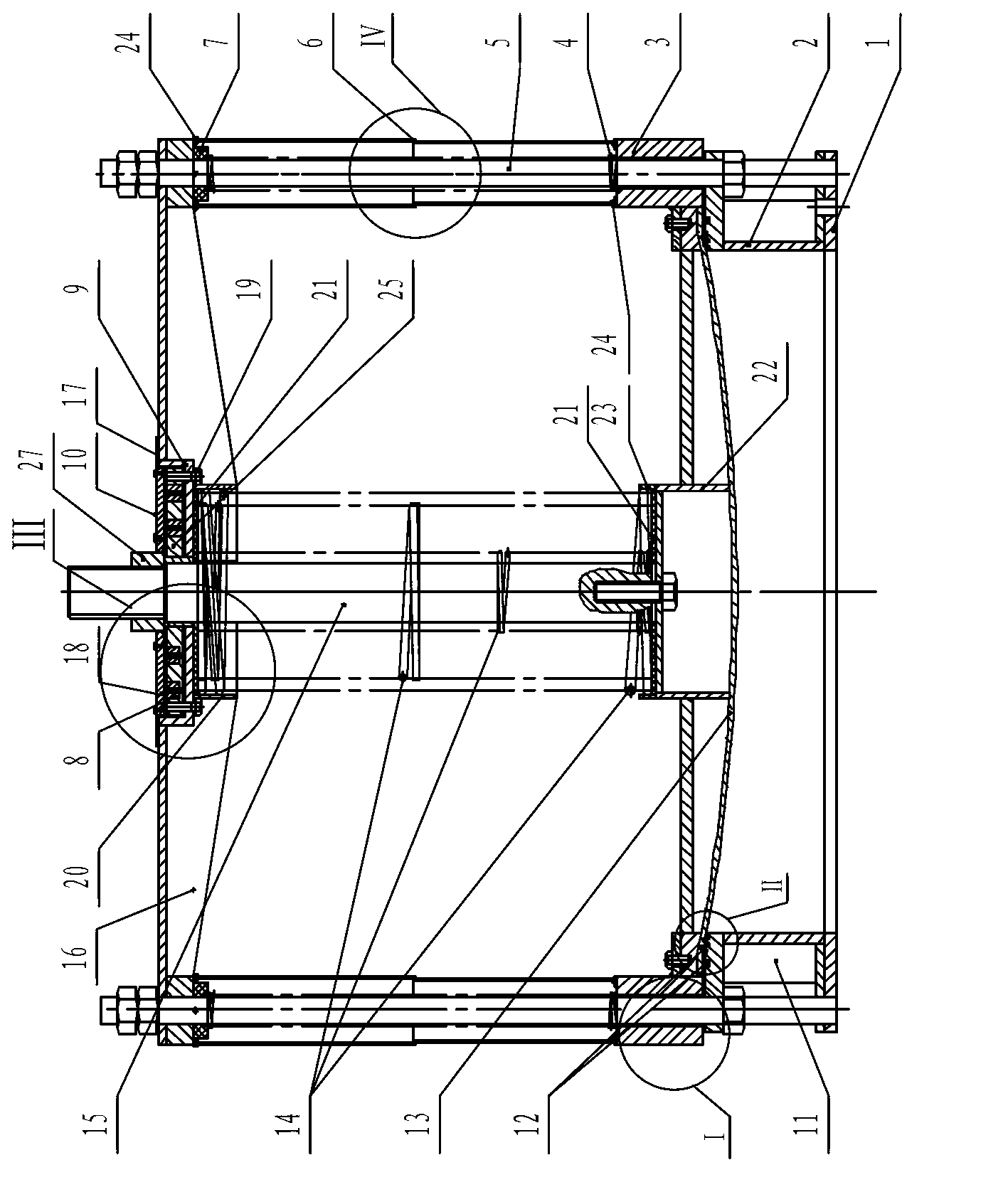

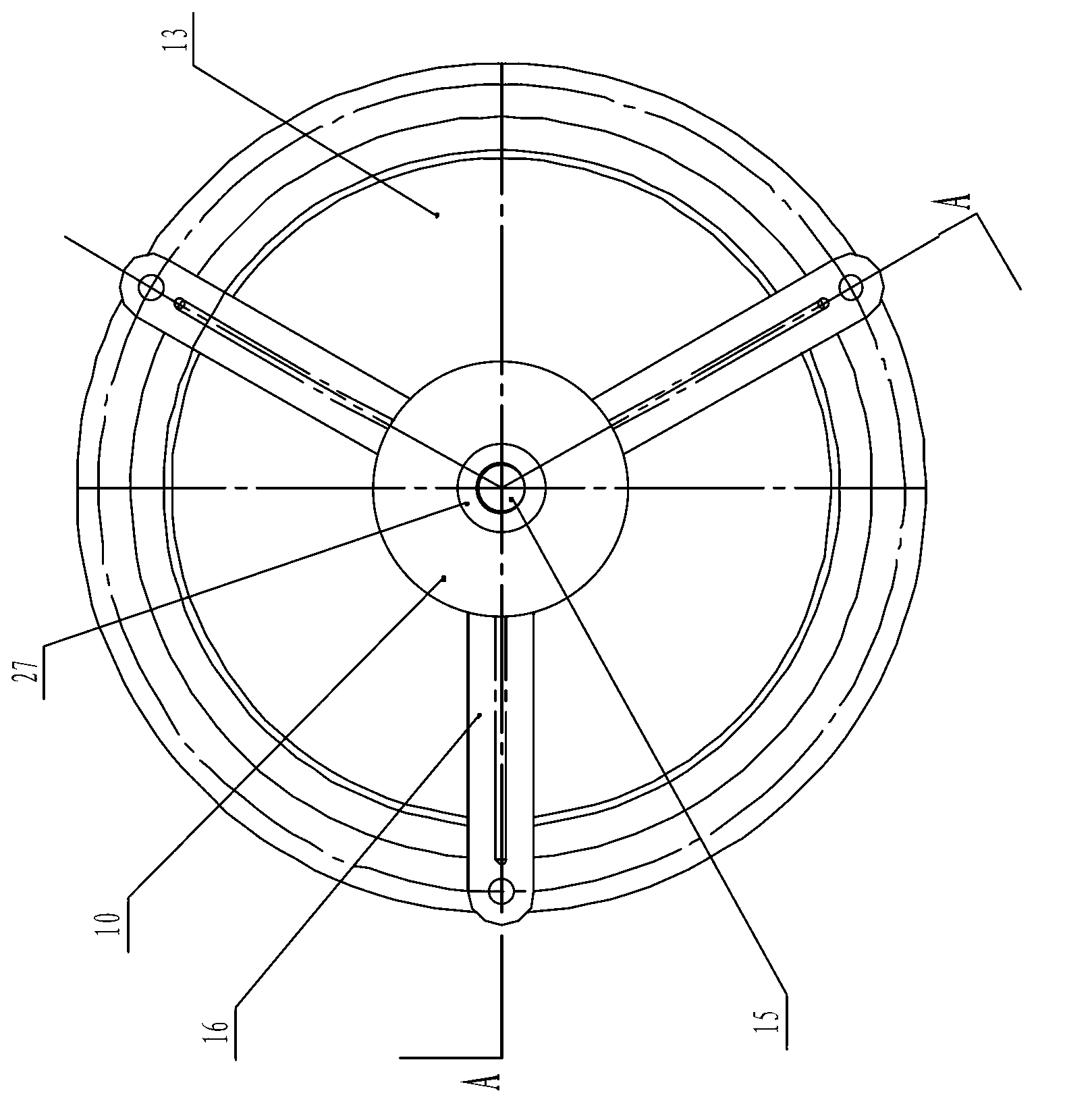

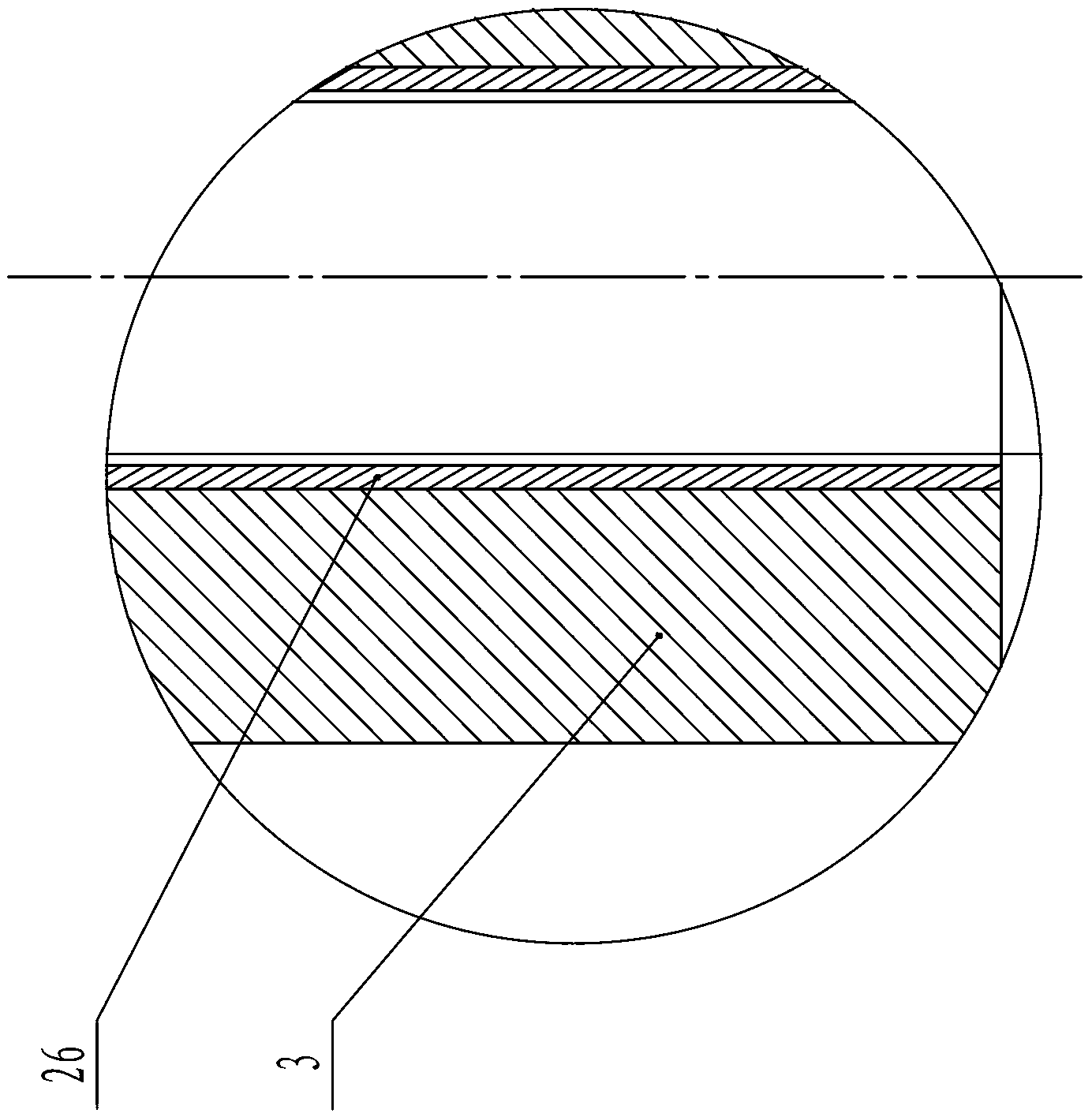

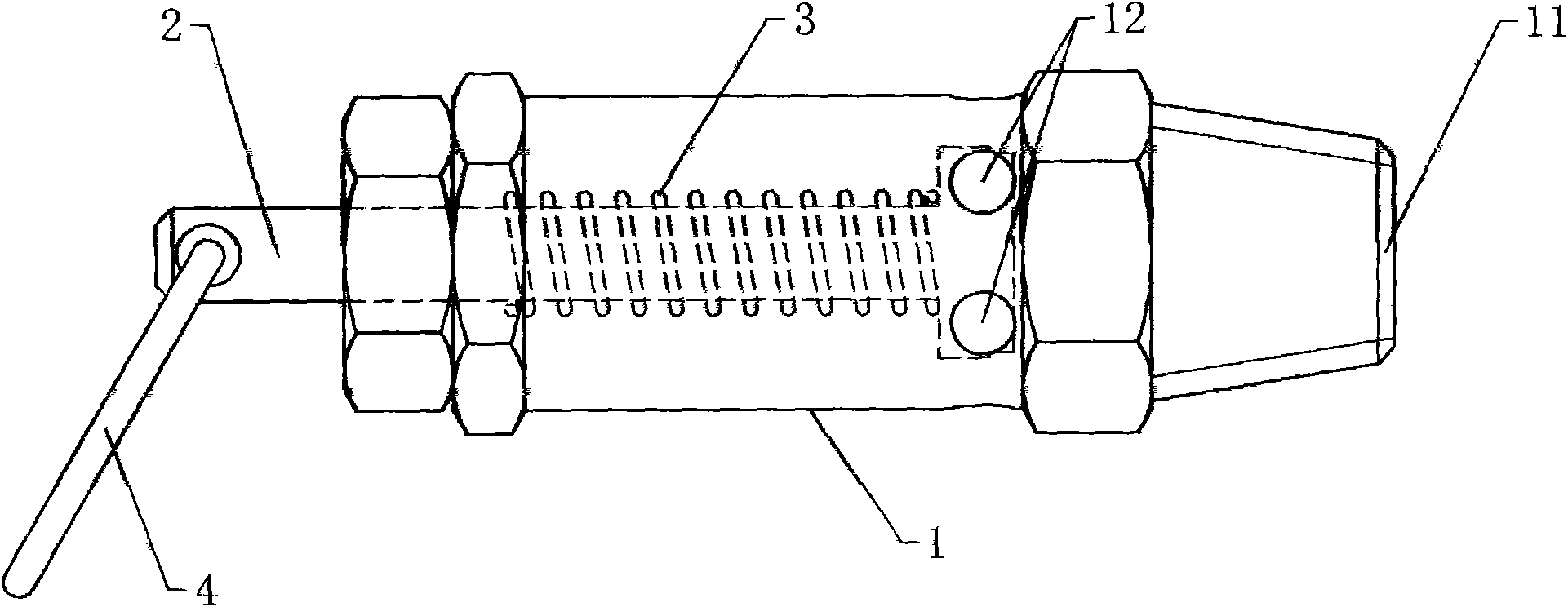

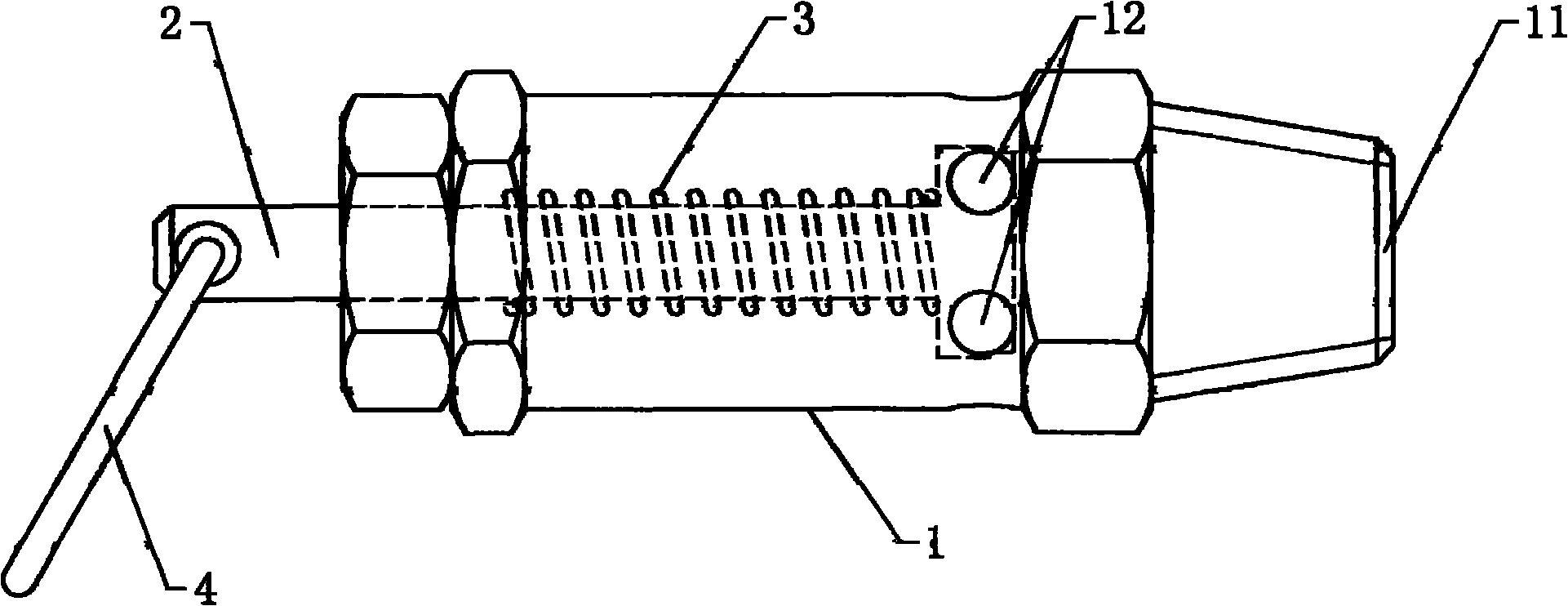

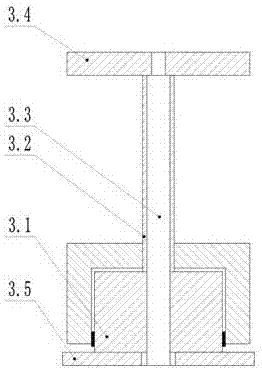

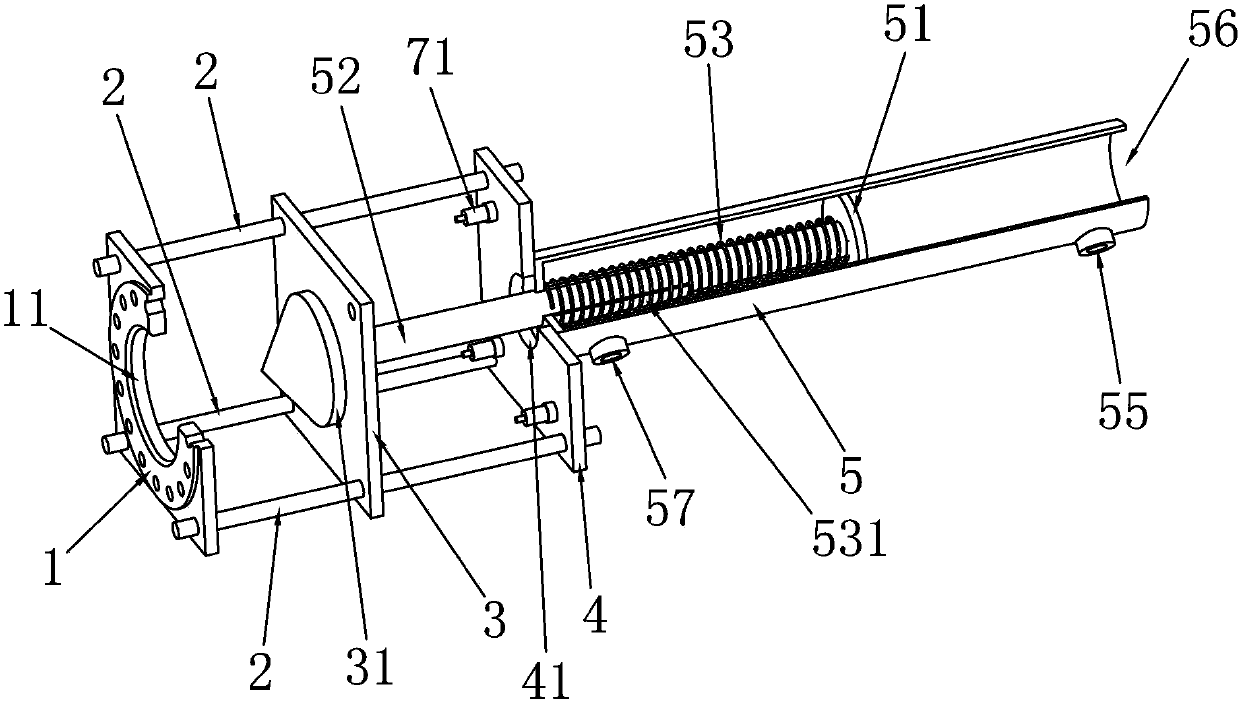

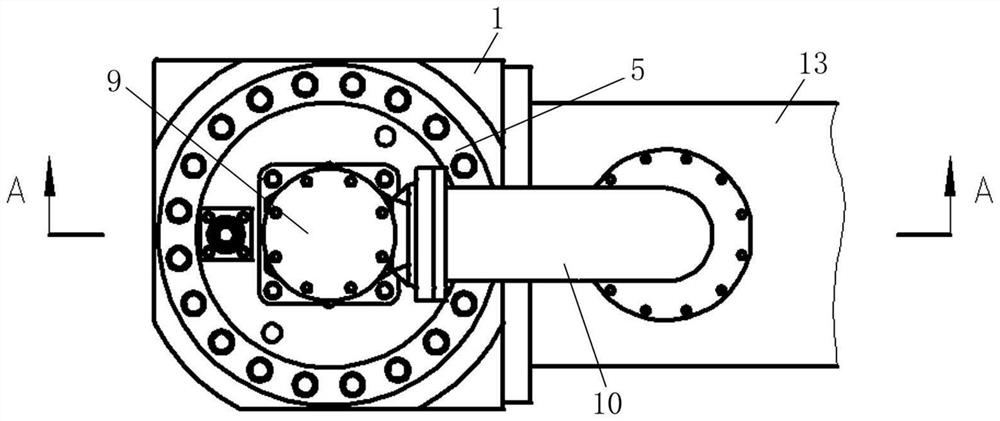

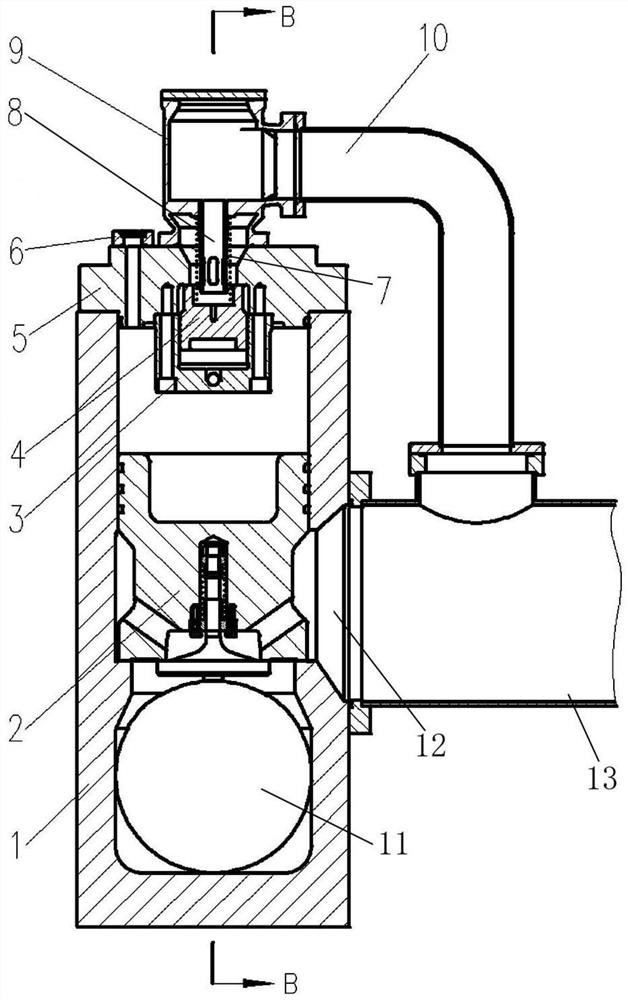

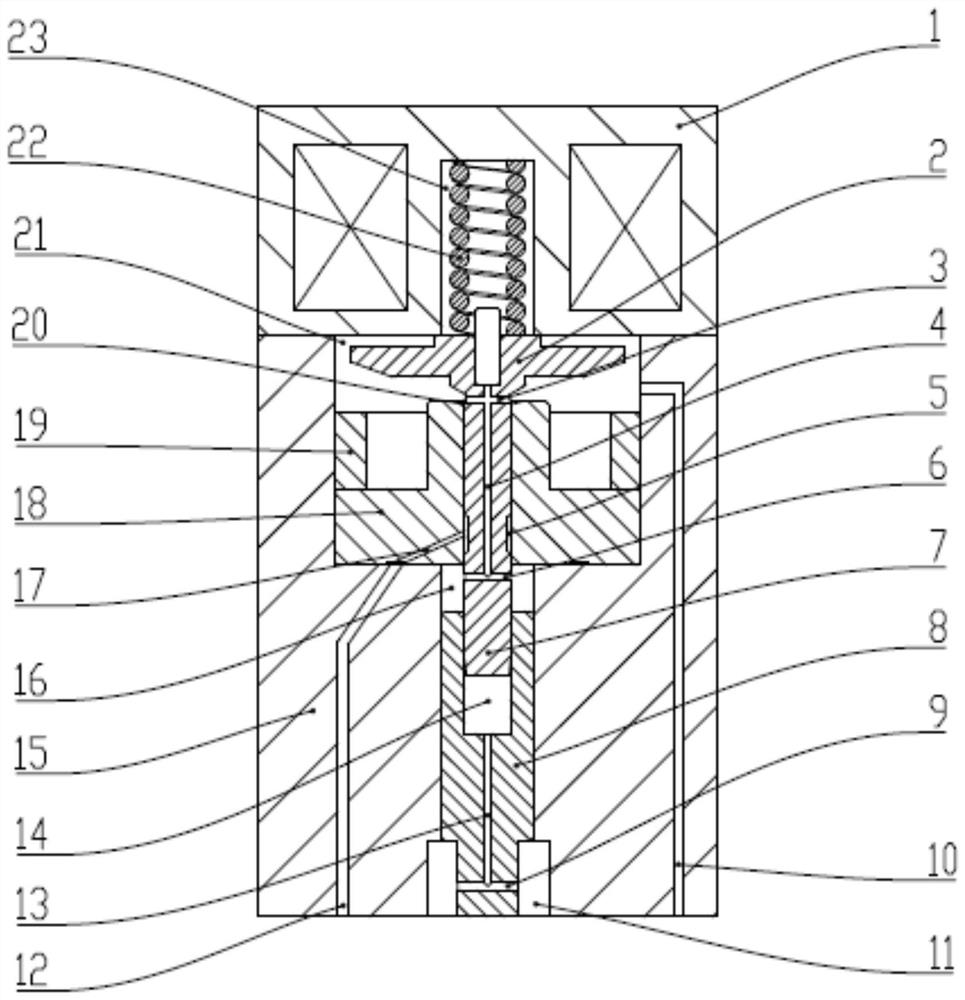

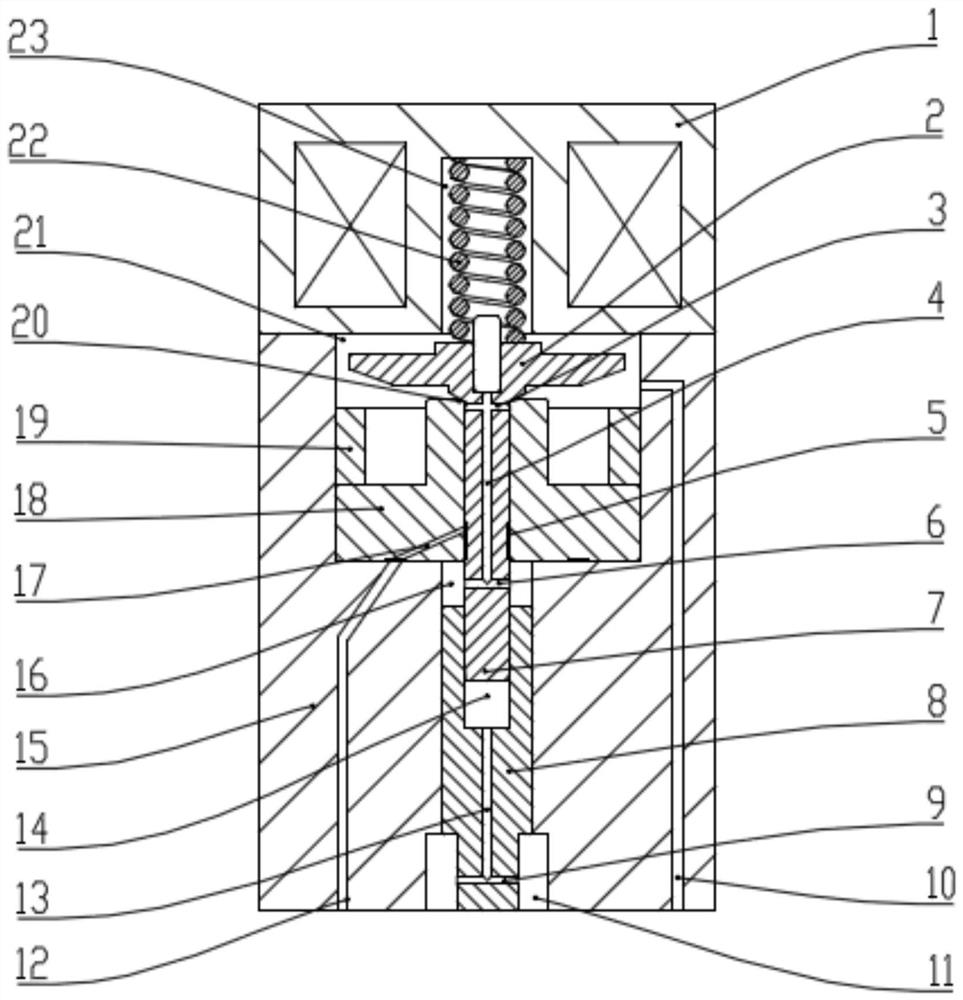

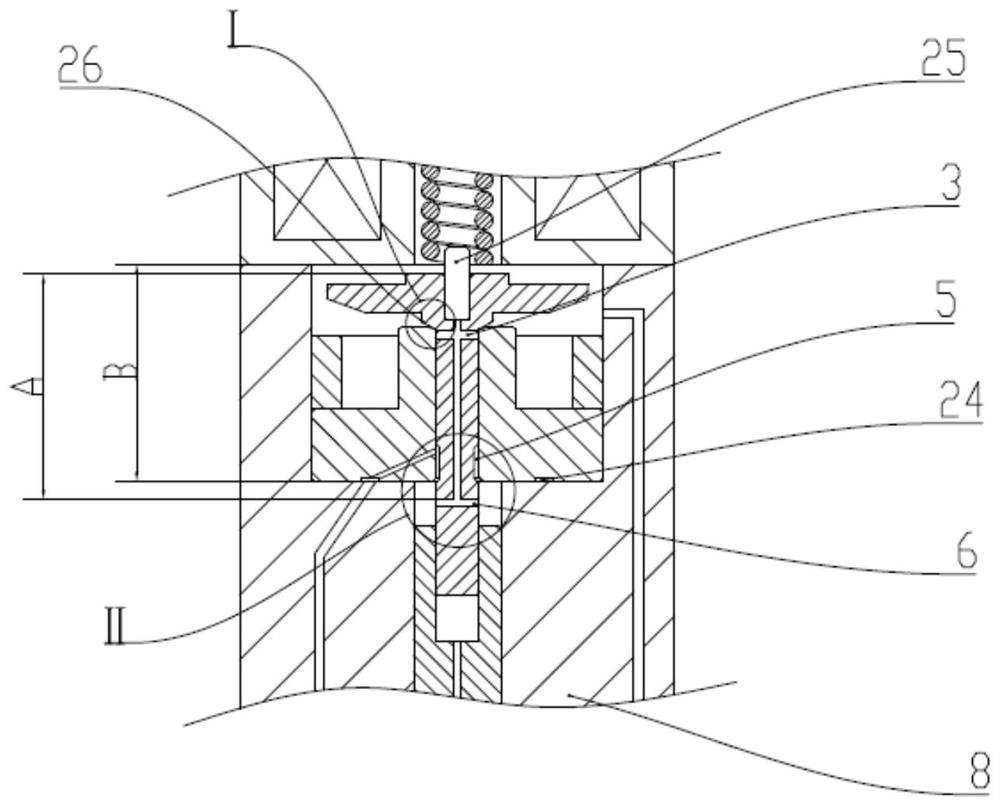

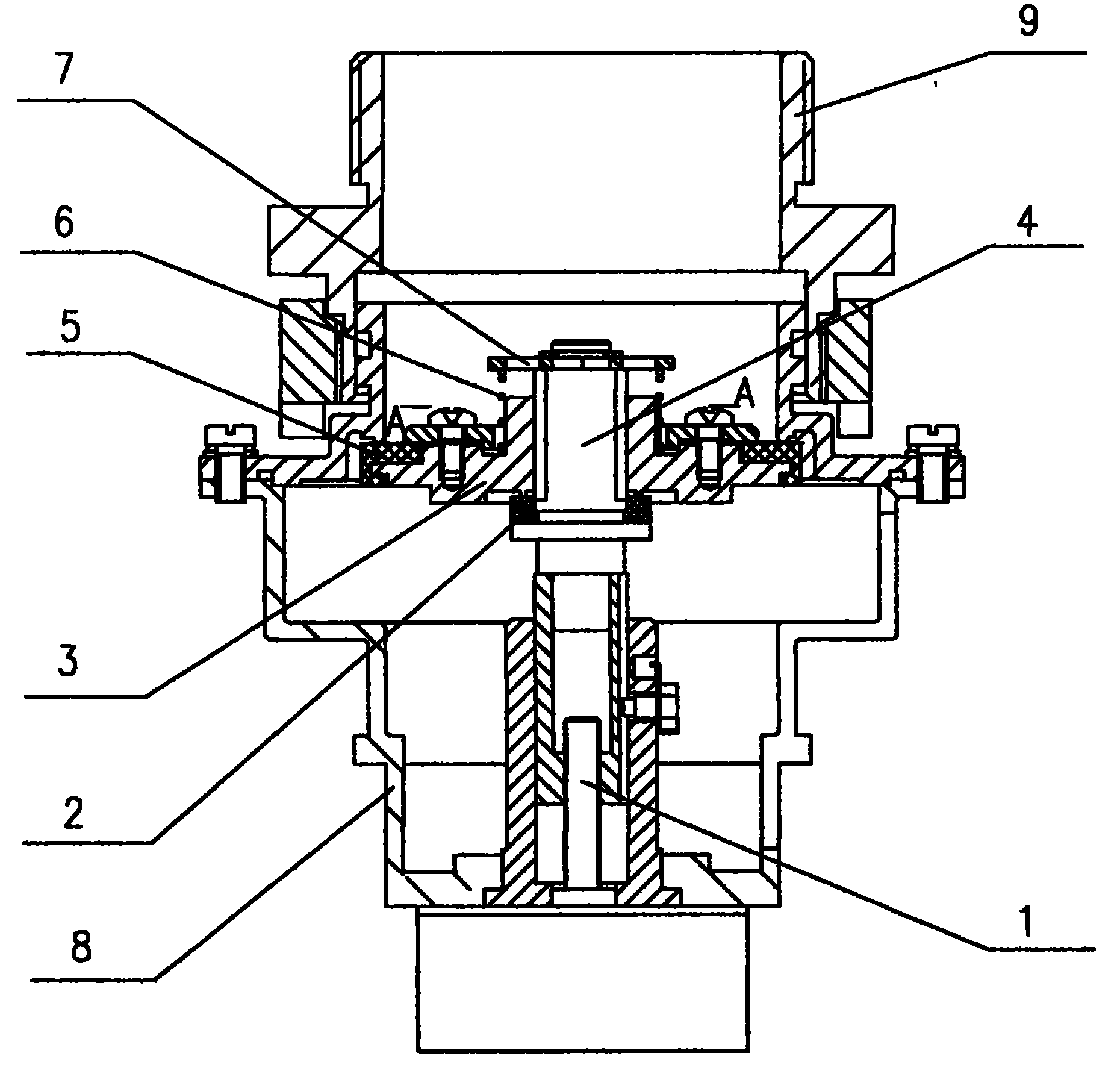

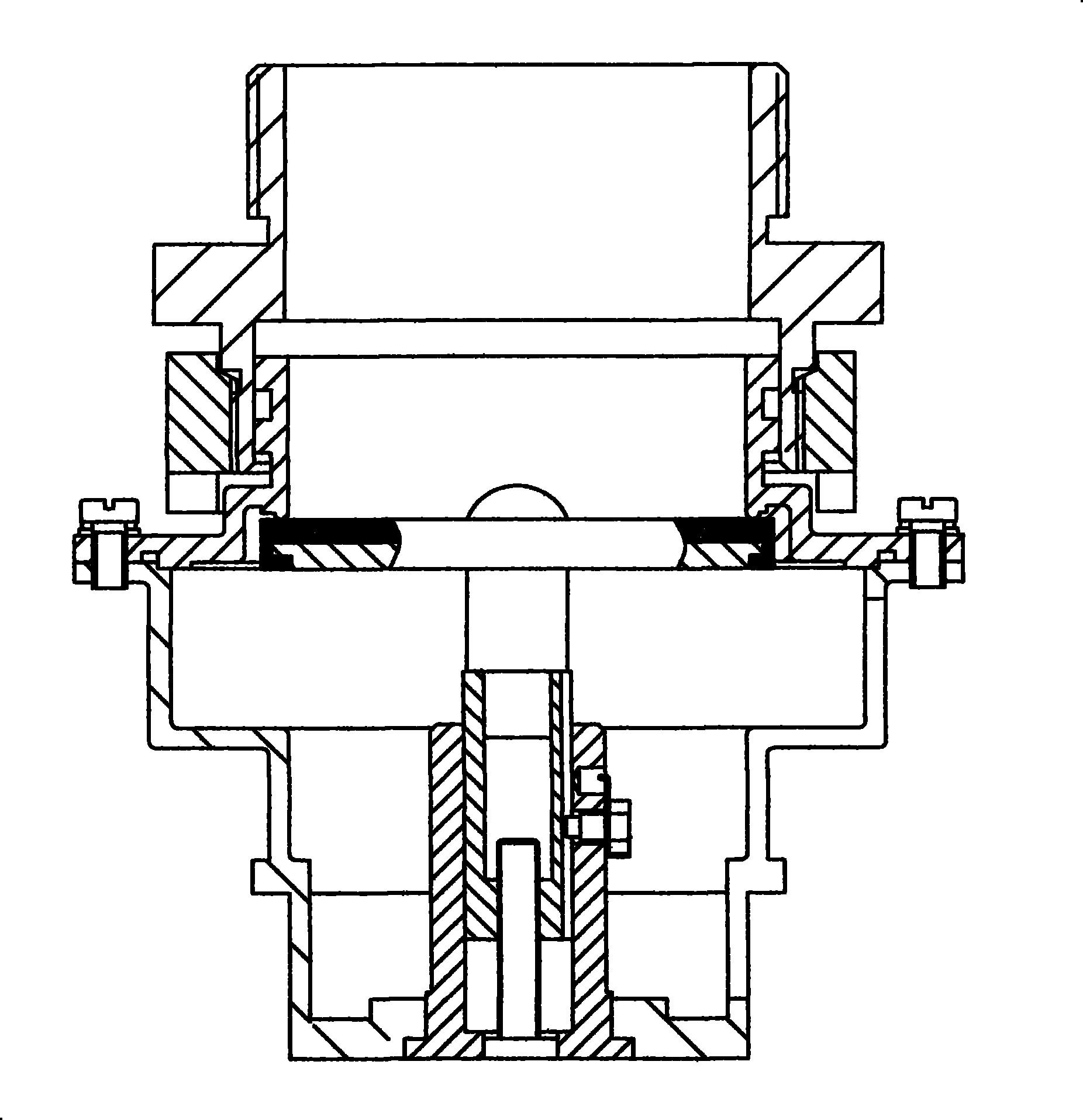

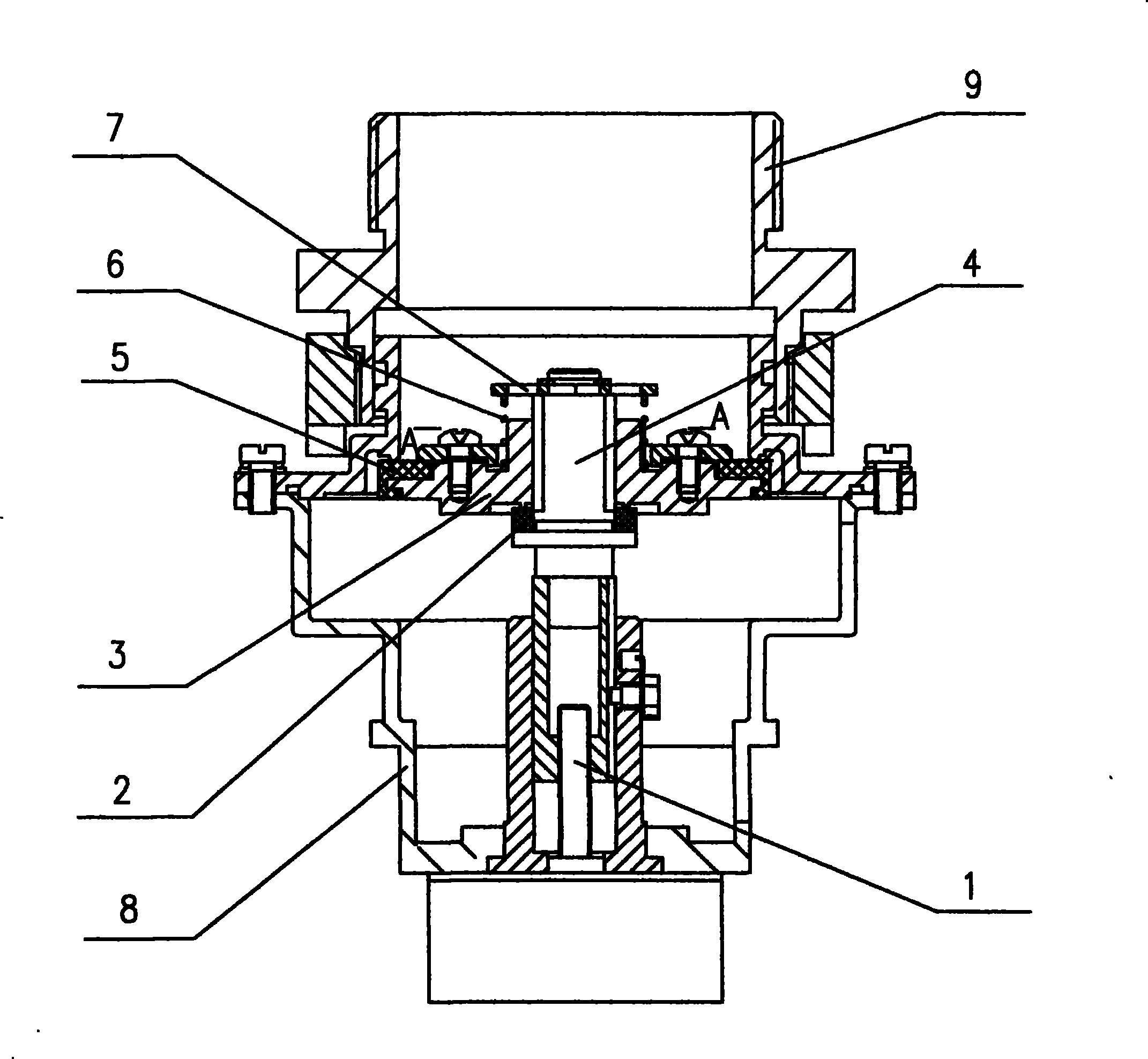

Quick-opening valve for steam explosion device

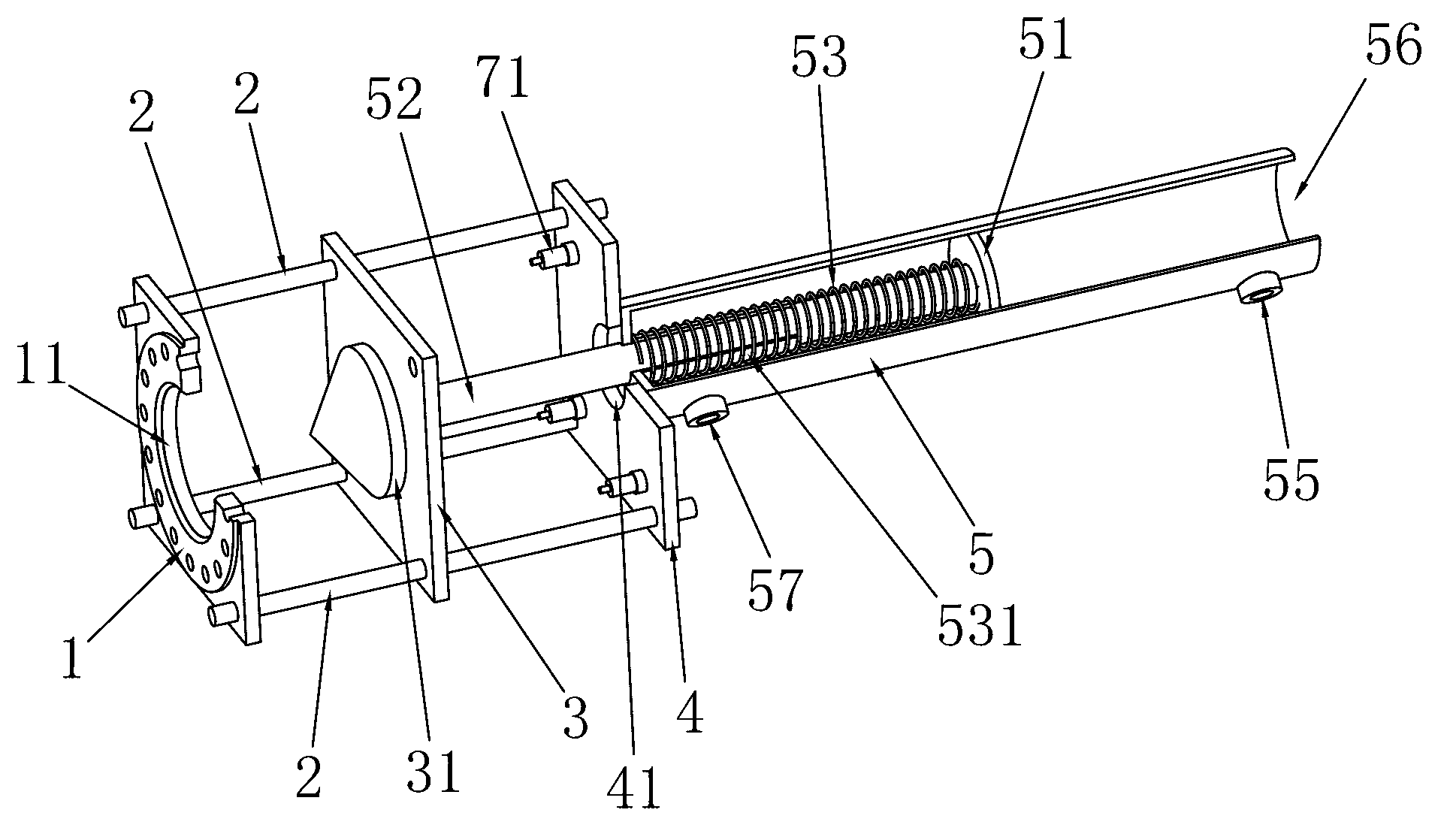

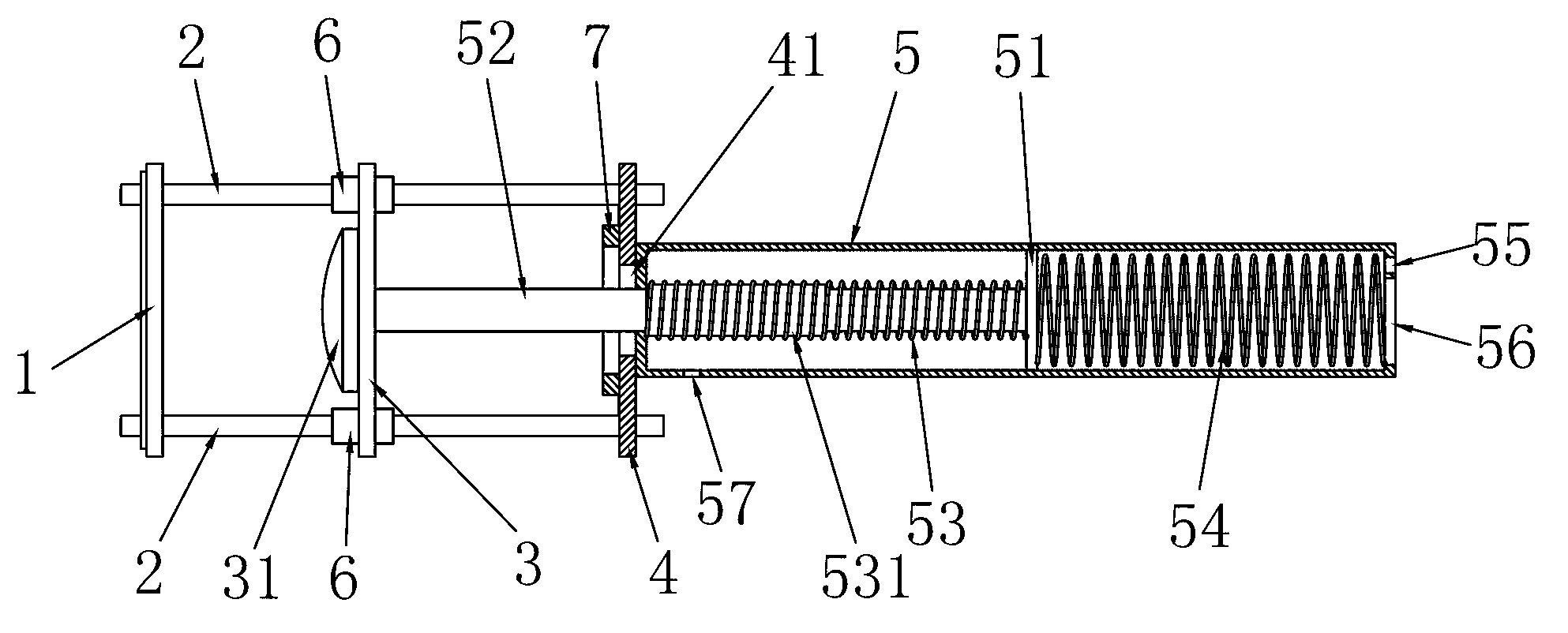

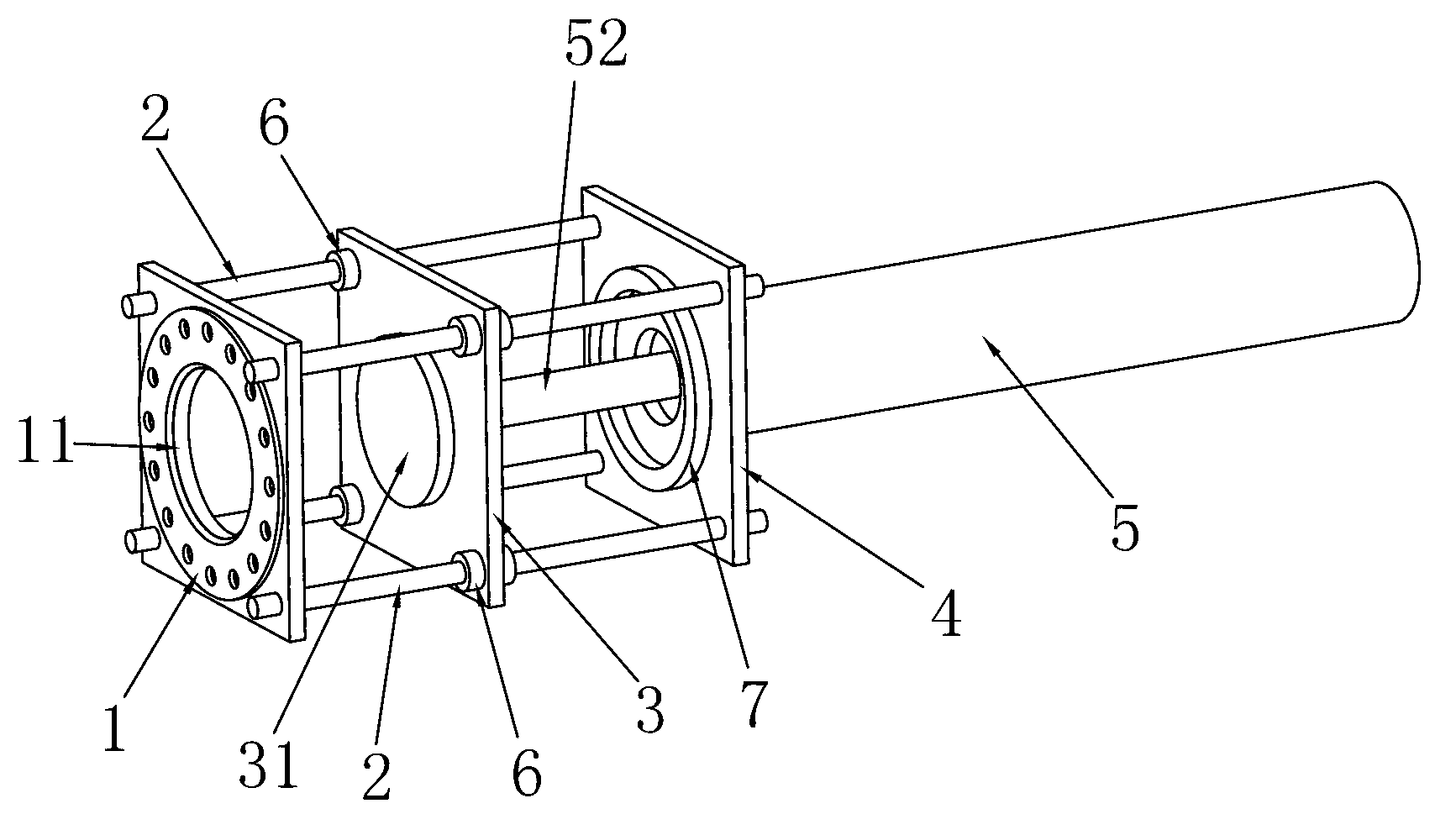

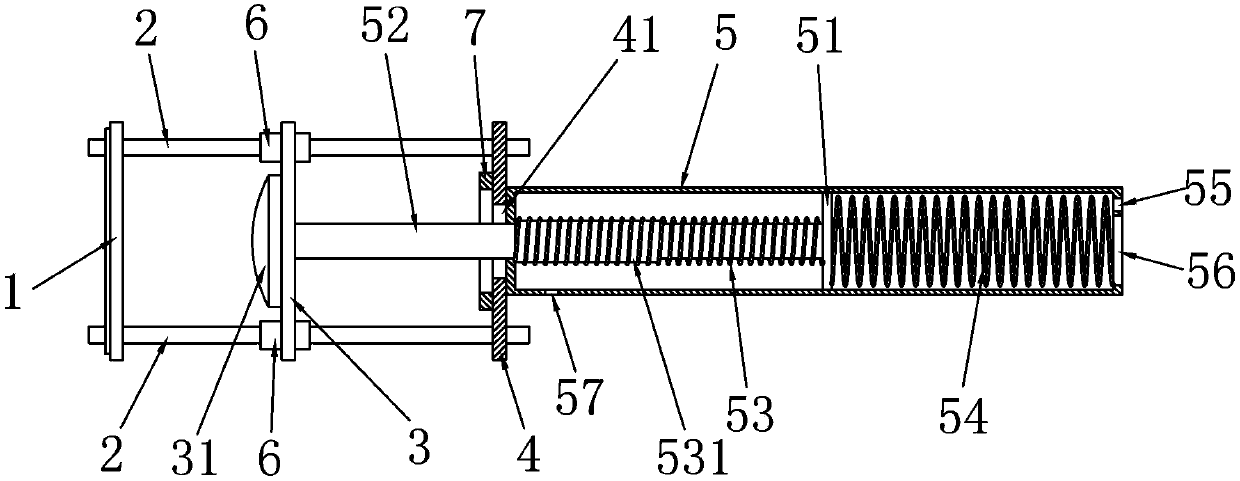

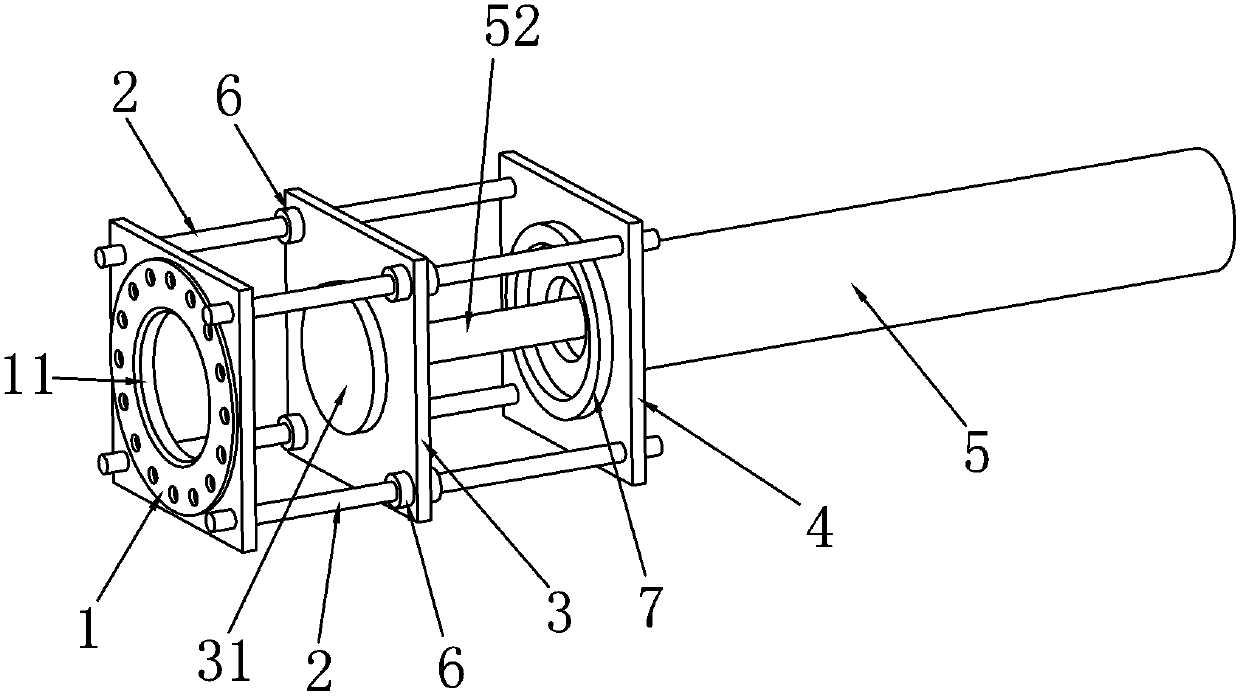

ActiveCN103075524AFast pressure reliefExtended service lifeOperating means/releasing devices for valvesLift valveEngineeringElectromagnetic valve

The invention provides a quick-opening valve for a steam explosion device. The invention relates to a valve, in particular to a gate valve used for a steam explosion machine. The invention aims at providing a quick-opening valve for a steam explosion device, which is suitable for the steam explosion device, is simple in structure and can realize quick opening of the valve. The quick-opening valve for the steam explosion device comprises a seal disc (1) provided with a valve hole (11) in the middle part, at least two slide bars (2) which are parallel to each other, a valve body plate (3) capable of sliding along the slide bars, a valve body (31) and a valve seat plate (4), wherein a buffer device is arranged on the end surface, close to the valve body plate, of the valve seat plate; the other end surface of the valve seat plate is fixedly provided with an oil cylinder body (5); a piston rod (52) passes through a through hole (41) and is fixedly connected with the valve body plate; the oil cylinder body is internally provided with a pressure spring (53) and / or a tension spring (54); one end of the oil cylinder body is provided with a vent hole (57), and the other end of the oil cylinder body is provided with a first oil through hole (55) and a second oil through hole (56) which have different sizes; and the quick-opening valve also comprises two electromagnetic valves which are respectively communicated with the two oil through holes.

Owner:李楠 +1

A test device and test method for simulating tire burst

ActiveCN112014124BFast pressure reliefThe process of simulating a flat tire is realVehicle tyre testingEngineeringCylinder block

The invention discloses a test device for simulating tire bursting, comprising: a cylinder body, which is provided with a plurality of first through holes; a cover body, arranged above the cylinder body, and the cover body and the cylinder body There is a pressure-holding space between the bodies, and the cover can move up and down relative to the cylinder to seal or open the pressure-holding space; a mounting plate is used to fix the cylinder and drive the cylinder; the mounting plate A plurality of through grooves are opened along its radial direction, and a plurality of said through grooves can be arbitrarily formed into at least two groups of through grooves for adapting tires of different specifications; The expansion and contraction of the cylinder and the collection of tire pressure parameters. In this application, a plurality of first through holes are set on the cylinder to connect the pressure holding space and the inner cavity of the tire. The air pressure of the tire cavity makes the tire inner cavity depressurize more quickly, so that the simulated tire blowout process is more realistic.

Owner:CATARC AUTOMOTIVE QUALITY INSPECTION CENT NINGBO

Internal-pressure-cylinder pressure testing method and system

InactiveCN105092375AFast pressure reliefEasy to recycleMaterial strength using tensile/compressive forcesInternal pressureAxial compression

The invention discloses an internal-pressure-cylinder pressure testing method and a system, and belongs to the technical field of examination equipment. According to the method, a solid elastic material is employed for replacing a conventional compression medium, and the solid elastic material is processed into a cylindrical compression body and is put into a test cylinder, the compression body generates radial expansion under the axial compression force and stresses the test cylinder, and an expected internal pressure and a loading process are obtained by controlling the loading speed of a press. If the test cylinder fails during an experiment, because the compression body is easily compressed, the pressure in the test cylinder rapidly decreases, and a large amount of energy is absorbed by the compression body. Therefore, the destroying capability of the residual energy to test on-site equipment and personnel is substantially reduced.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Automatic opening and closing pressure-relief anti-explosion safety valve for pipeline system

ActiveCN103062459ASmall detonation resistanceExplosion speed is fastEqualizing valvesSafety valvesHigh pressureSafety valve

The invention relates to an automatic opening and closing pressure-relief anti-explosion safety valve for a pipeline system. The automatic opening and closing pressure-relief anti-explosion safety valve is characterized in that three guide rod holes in circumferential uniform distribution are arranged on each of flanges arranged on the upper surface and the lower surface of a valve body seat, a spherical surface combination seal part is mounted in a seal part groove arranged on the flange on the upper surface of the valve body seat, a valve bonnet is in a hollow half-conisphere shape, three guide rod sleeves are fixedly welded on the periphery of the valve bonnet, the valve bonnet presses the spherical surface combination seal part arranged on the upper surface of the valve seat, the lower ends of three guide rods are assembled in the guide rod holes of the valve body seat, a support is fixed at the top ends of the three guide rods, an adjustable magnetic force disc is fixed at the center of the support, the lower end of a main guide rod is fixed in the middle of the valve bonnet, an auxiliary sucker is fixedly mounted after an upper end of the main guide rod penetrates out of a central hole of the adjustable magnetic force disc, three groups of buffer springs are mounted on the main guide rod, and dustproof protecting sleeves are arranged on the peripheries of auxiliary return springs mounted on the three guide rods. The automatic opening and closing pressure-relief anti-explosion safety valve for the pipeline system has the advantages of high pressure relief speed, good sealing performance, high temperature resistance, automatic opening and closing accuracy, reusability and avoidance of replacement.

Owner:盐城市瑞恒电力石化设备有限公司

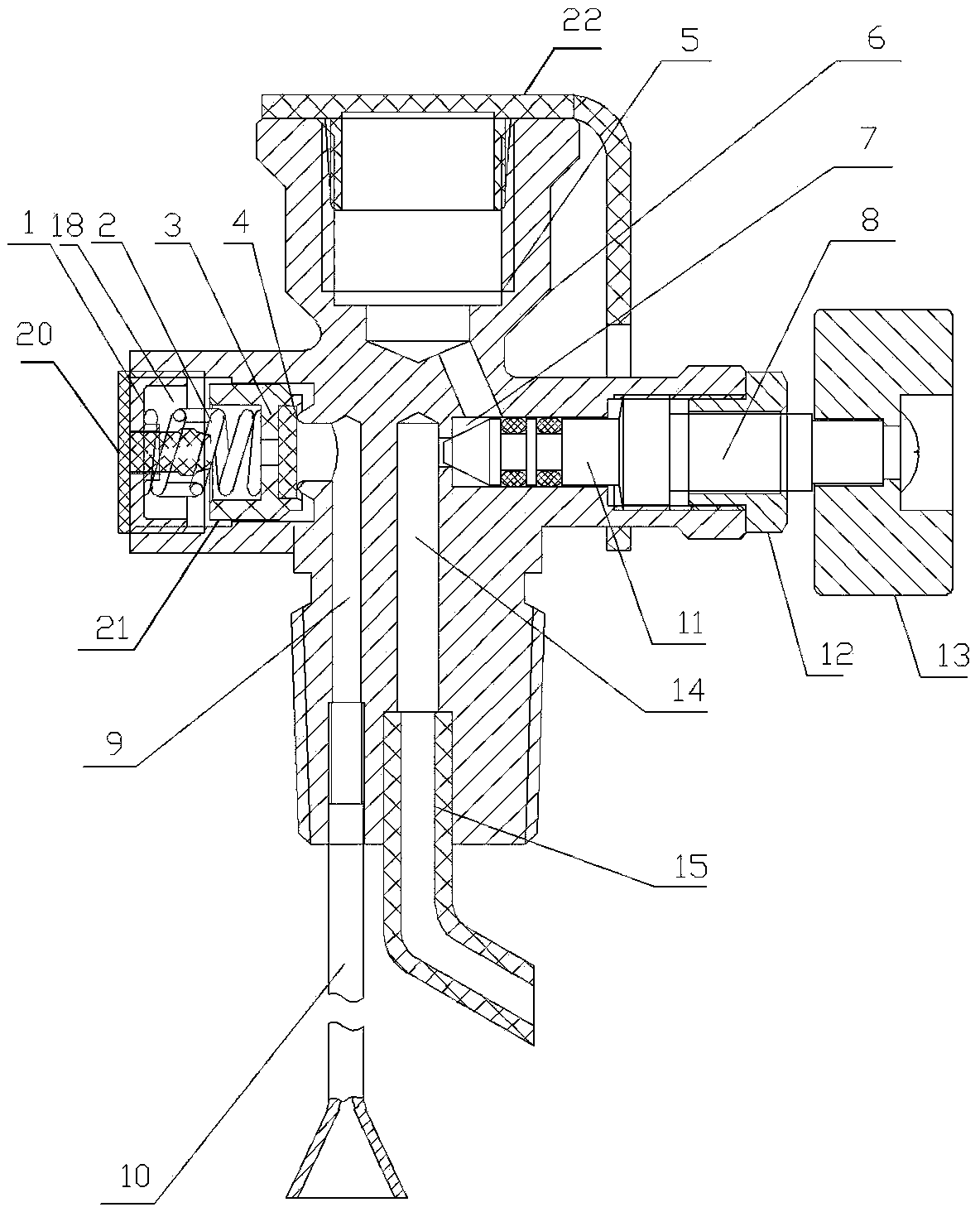

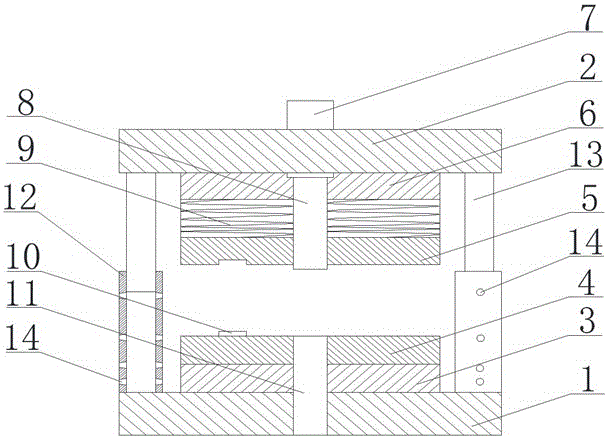

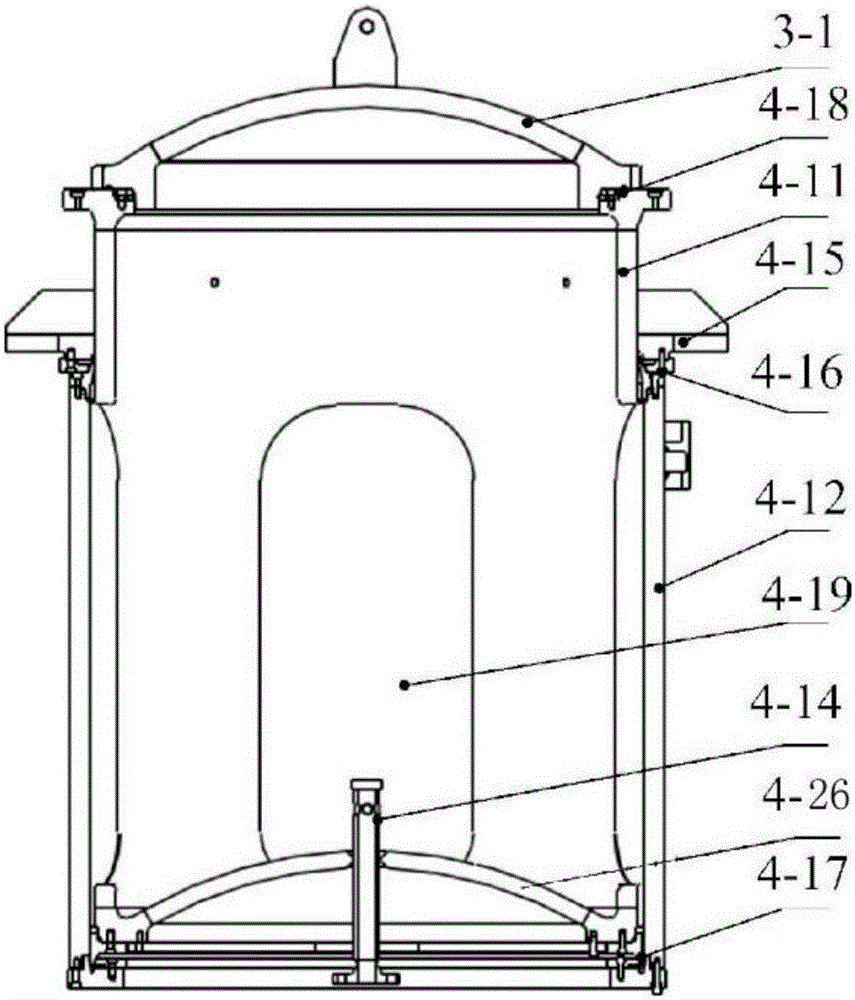

Combined pressure relief valve

ActiveCN104712798AFast pressure reliefImprove work efficiencyEqualizing valvesSafety valvesEngineeringRelief valve

The invention provides a combined pressure relief valve comprising a valve element, a manual pressure relief valve, a main oil duct, an auxiliary oil duct, spring bases and the like. Primary pressure relief and secondary pressure relief can be achieved, and manual pressure relief can be achieved under the special circumstances such as hydraulic control failures or power failures. The combined pressure relief valve is implemented, so that when a main oil cylinder of a hydraulic machine relieves pressure, the pressure relief speed is increased, the working period is shortened, the size of the valve is reduced, and operation and maintenance are convenient.

Owner:天津帝广机电设备有限公司

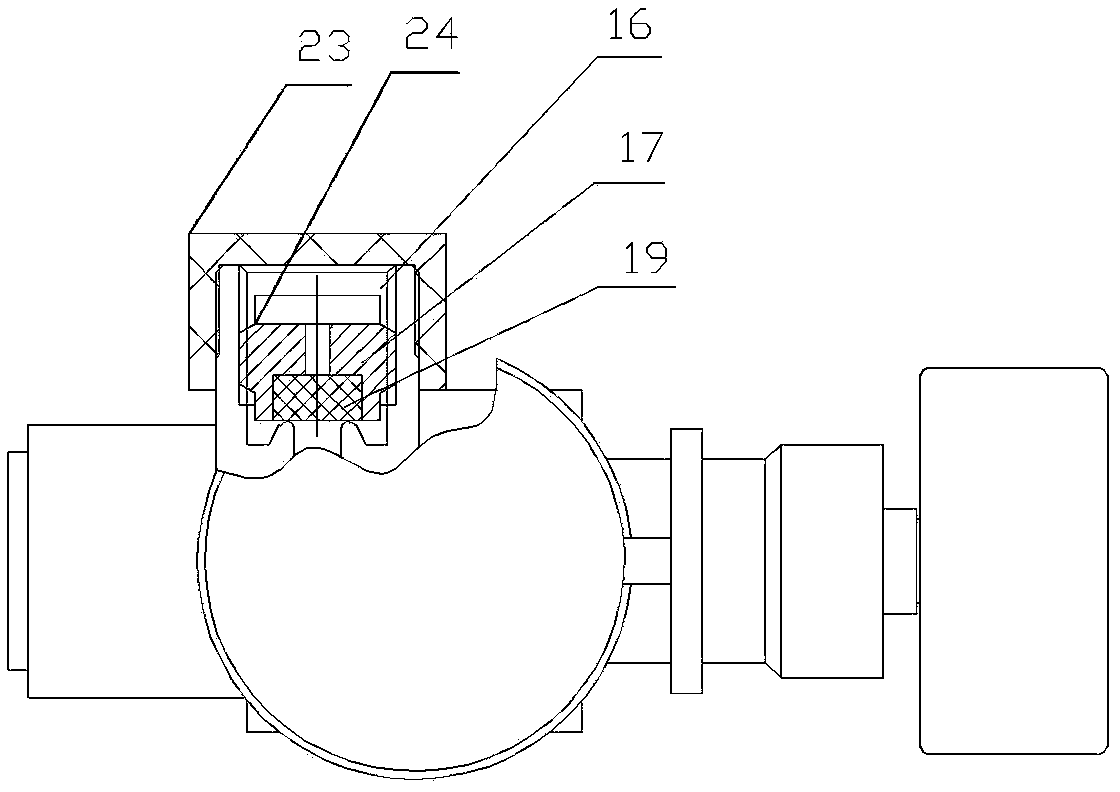

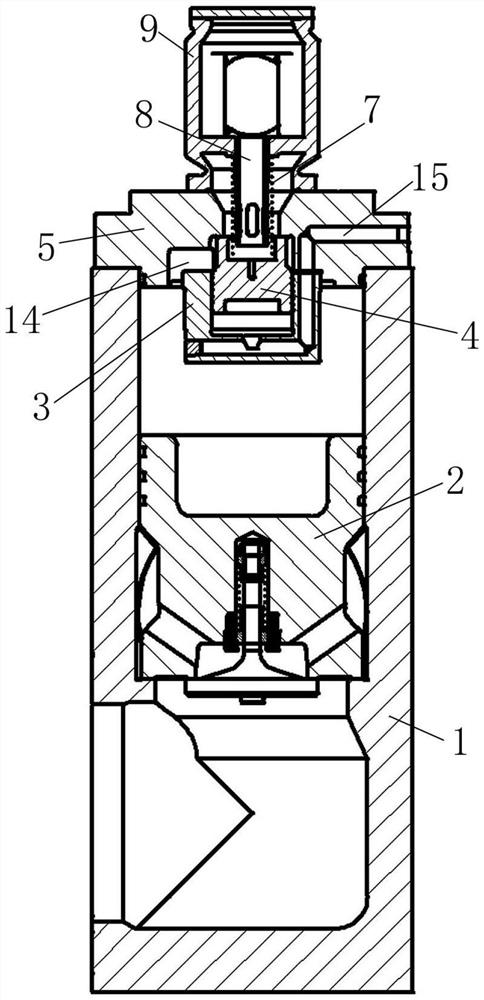

Fuel gas cylinder valve

ActiveCN103836242AExtended service lifeNot lostEqualizing valvesSafety valvesEngineeringAtmospheric pressure

The invention relates to a fuel gas cylinder valve. The fuel gas cylinder valve comprises a valve body, wherein the valve body is provided with a gas connection passage and a gas port communicated with the outer side of the valve body, the gas connection passage is communicated with or closes off the gas port trough a switch valve, an automatic pressure relief device is installed on the valve body, the automatic pressure relief device comprises a pressure relief passage arranged on the valve body and a pressure relief port which is arranged on the valve body and can be communicated with the outer side of the valve body, the inner surface of the pressure relief port is arranged in a step mode, the inner diameter of the inside of the pressure relief port is smaller than the inner diameter of the outside of the pressure relief port, the inside of the pressure relief port is sealed and provided with a movable block in a sliding mode, a spring seat is arranged outside the pressure relief port, a pressure relief spring is connected between the movable block and the spring seat, the upper end of the pressure relief passage is communicated with or closes off the pressure relief port through the movable block, the lower end of the pressure relief passage is connected with a pressure relief pipe extending out of the inner side of the valve body, and a horn-shaped opening is arranged at the end of the pressure relief pipe. The fuel gas cylinder valve can achieve automatic and rapid pressure relief through the automatic pressure relief device, guarantees stability of the air pressure inside a fuel gas cylinder, and guarantees safety.

Owner:NINGBO JINJIAJIA VALVE

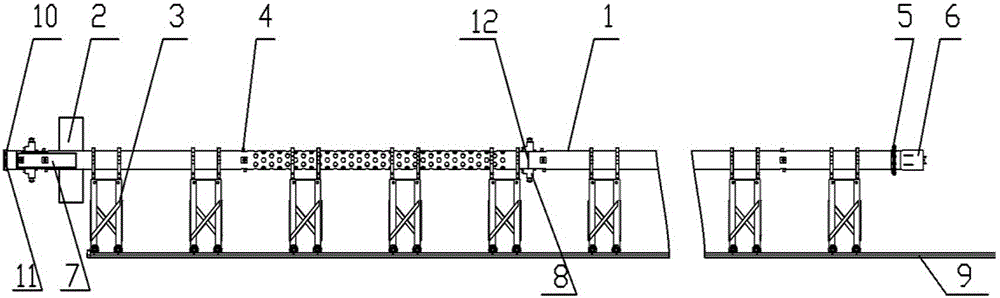

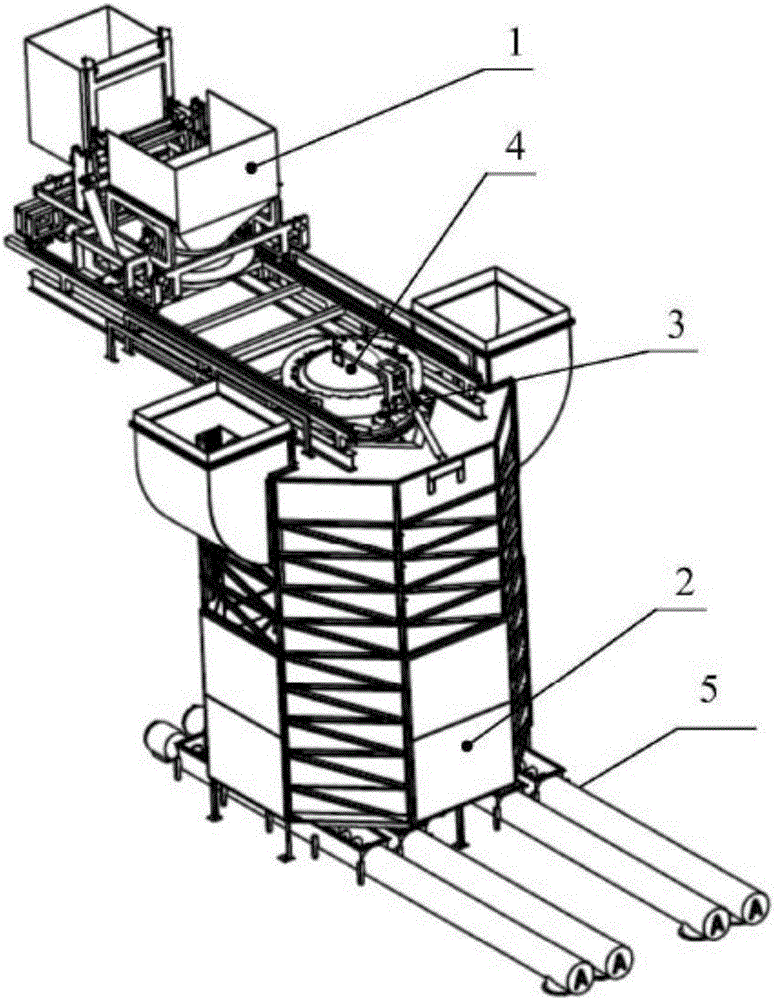

Production line of resistance silencing tube for vehicle

ActiveCN106140956AAvoid damageSmooth pressure reliefPerforating toolsShaping safety devicesProduction linePunch press

The invention discloses a production line of a resistance silencing tube for a vehicle. The production line of the resistance silencing tube for the vehicle comprises a lower die holder, an upper die holder and a die handle. A punch fixing plate and guide rods are arranged on the bottom part of the upper die holder; a punch is arranged on the bottom part of the punch fixing plate; the upper end of the punch penetrates through the punch fixing plate; an emptying plate and guide sleeves matched with the guide rods are fixed to the lower die holder; a punched hole matched with the punch is formed in the emptying plate; a plurality of through holes are formed in side walls of the guide sleeves; the inside and the outside of each guide sleeve communicate through the through holes; and the lower ends of the guide rods stretch into the guide sleeves in a sliding way. According to the production line of the resistance silencing tube for the vehicle provided by the invention, the through holes are formed in the guide sleeves, so that compressed air or negative pressure cannot be formed inside the guide sleeves, air pressures inside and outside the guide sleeves are consistent during the vertical movement process of the upper die holder, and not only are the problems that the bore diameter of a workpiece formed through punching does not meet the specification, burrs exist around a hole, and the product quality is low since the impact force of the punch on the workpiece to be punched is reduced solved, but also a punch press is prevented from being damaged during the manufacturing process.

Owner:CHENGDU ZHIRONG ZHICHUANG INTPROP MANAGEMENT CO LTD

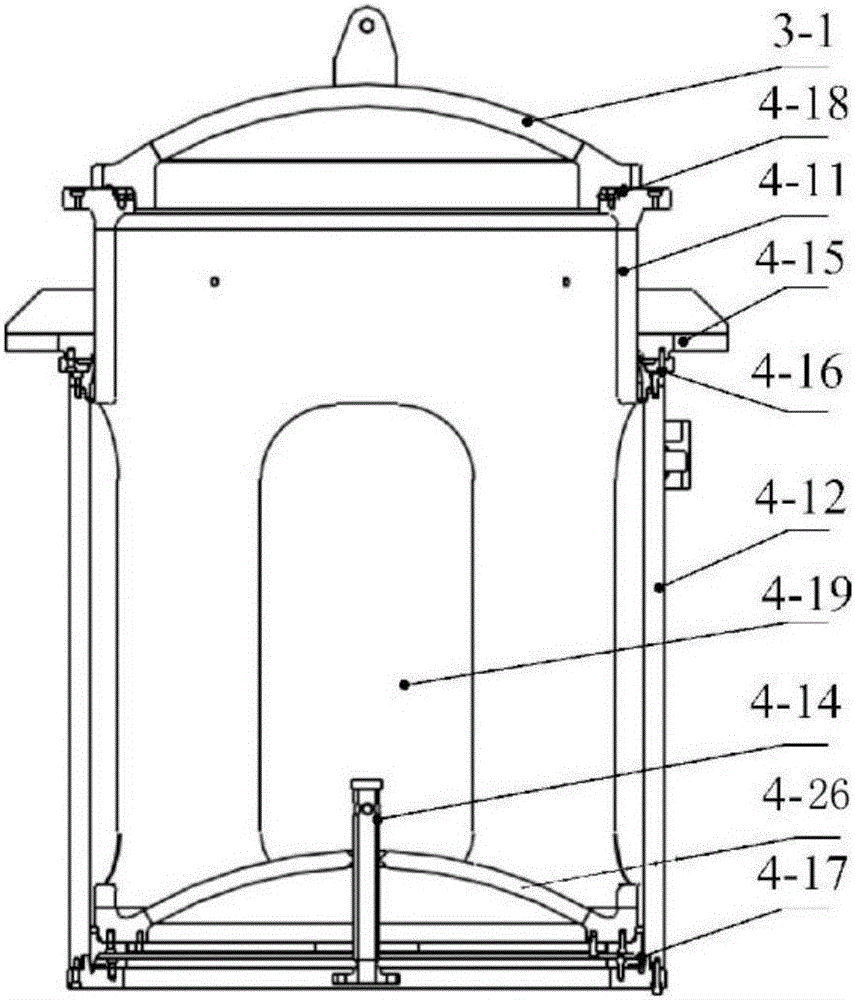

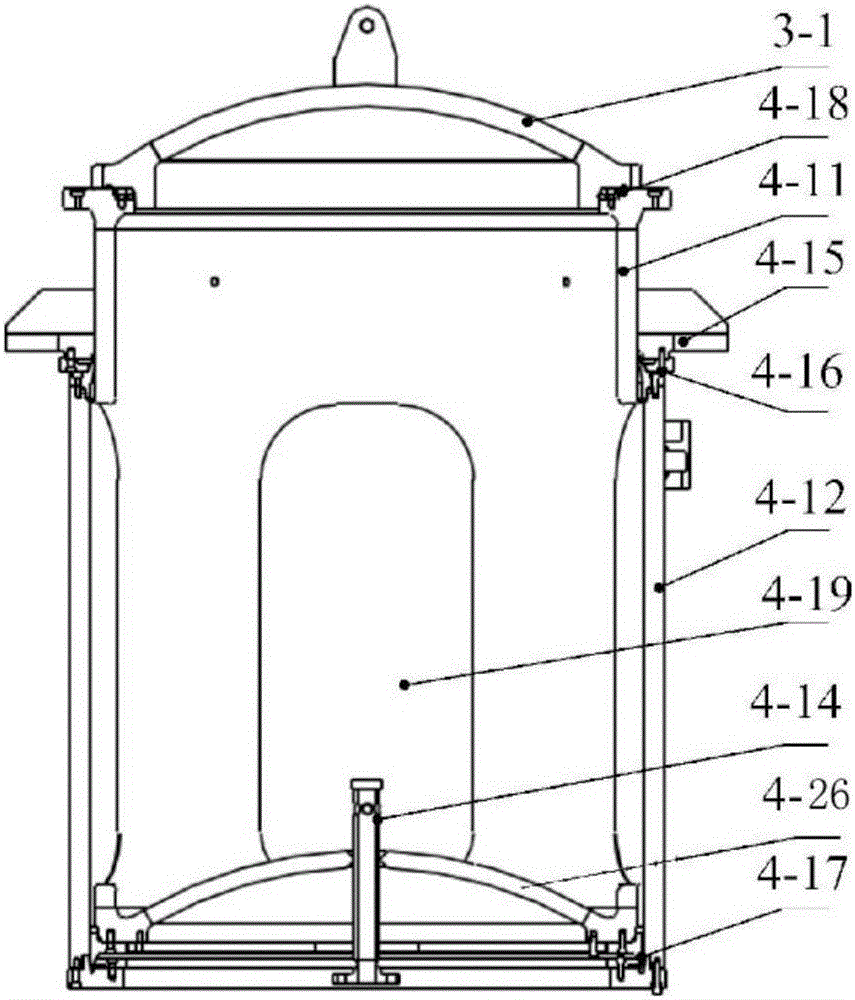

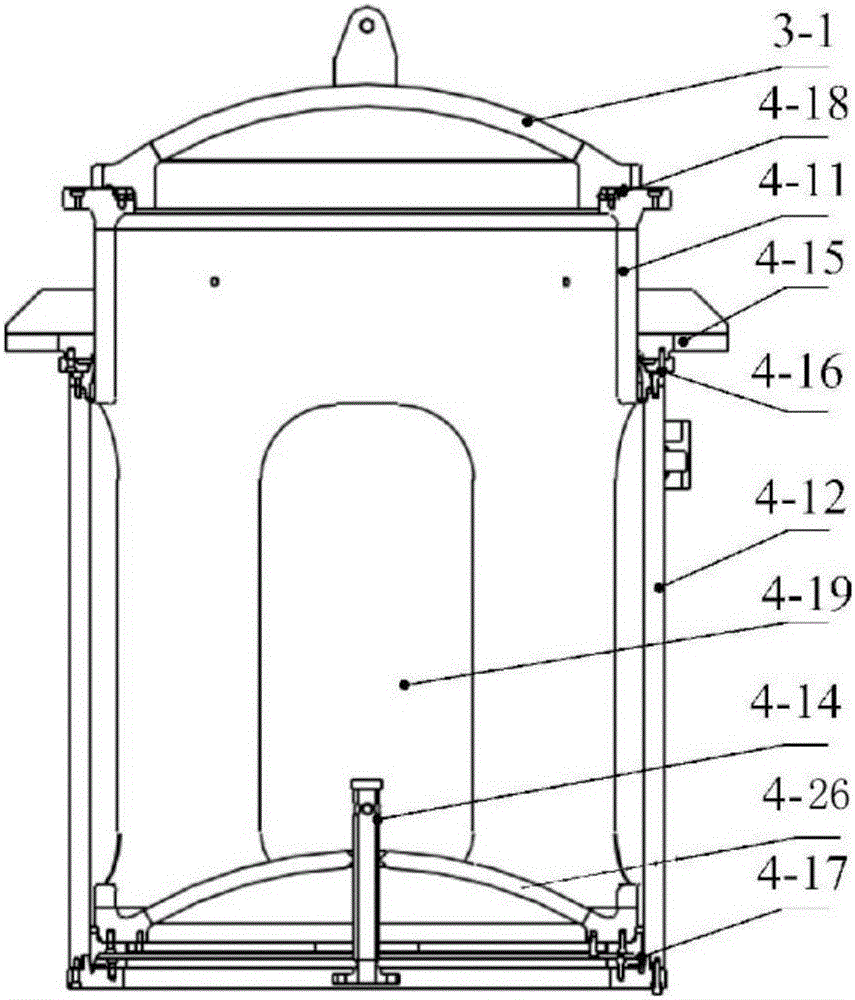

High sealing performance sealing device with separate cylinder barrels

InactiveCN106051198AImprove discharge efficiencyThe treatment effect is safe and reliableEngine sealsSolid waste disposalEngineeringHigh pressure

The invention discloses a high sealing performance sealing device with separate cylinder barrels, which comprises an upper cylinder battle and a lower cylinder; the lower cylinder is of a cylindrical structure with openings in two ends and sleeves the outer side of the upper cylinder barrel; the upper cylinder barrel comprises a steam valve port located in the bottom and a discharging port located in the side part, an outside steam pipeline is connected to the steam valve port and is used for injecting high temperature high pressure steam into the upper cylinder barrel, the lower cylinder barrel is connected to the upper cylinder barrel in a sliding manner, when the lower cylinder barrel slides to the uppermost end, the lower cylinder barrel closes the discharging port, and the upper cylinder barrel is sealed; and a cylinder cover of a cover opening device covers the top end of the upper cylinder barrel. The structure of the cover opening device is innovatively deigned, the cylinder cover and a locking ring adopt a wedge-shaped tooth interlocking structure, and the sealing is reliable; and a bolt can be adjusted such that the in-place precision of the cover opening and closing actions are is ensured.

Owner:TIANZI ENVIRONMENTAL PROTECTION EQUIP MFG TIANJIN

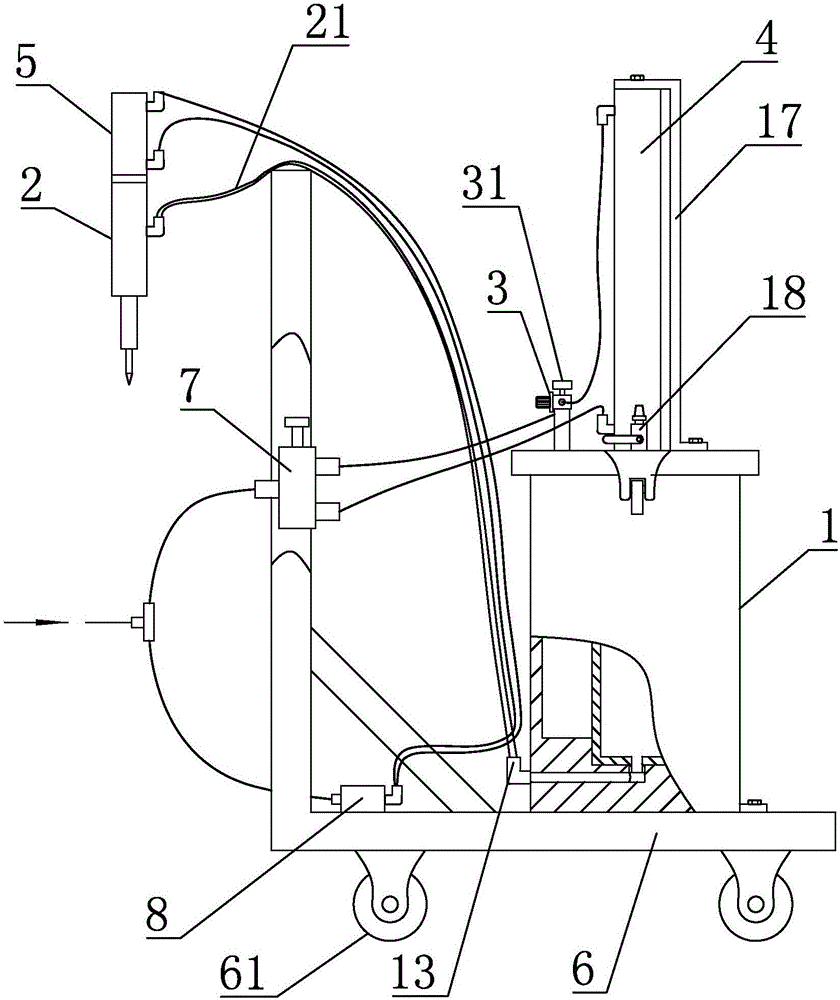

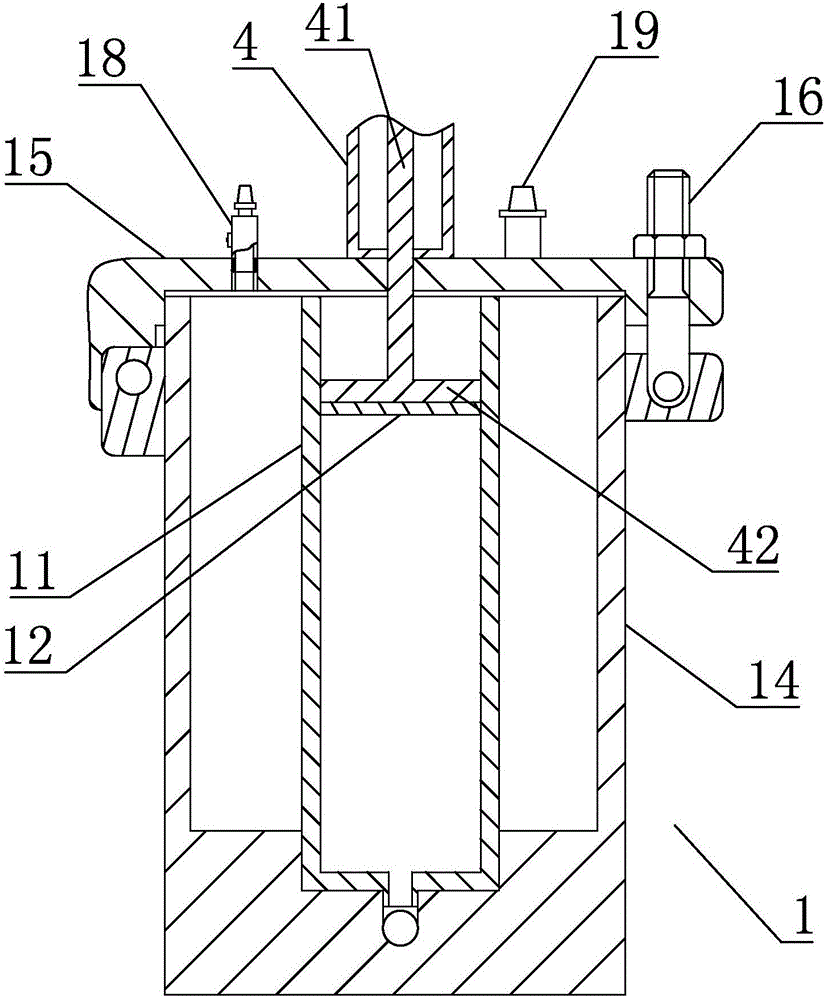

Glue dispenser for glue filling of air cylinders

InactiveCN106733444AFast replacementStable pressureLiquid surface applicatorsCoatingsEngineeringAir compressor

The invention discloses a glue dispenser for glue filling of air cylinders. The glue dispenser comprises an air source, a charging barrel and a glue dispensing gun, wherein air is supplied to the air source through an air compressor; and the charging barrel is used for containing glue. A glue barrel containing a fixed amount of glue can be installed in the charging barrel. A sealing cover capable of being pushed is arranged at the top of the glue barrel. An outlet in the bottom of the glue barrel communicates with a glue outlet formed outside the charging barrel. The glue dispensing gun is connected with the glue outlet through a glue pipe. The top of the charging barrel is provided with a pressure regulating valve communicating with the interior of the charging barrel. The pressure regulating valve is connected to the air source. The charging barrel is vertically installed on a movable trolley. Four movable wheels are installed at the bottom of the trolley. The charging barrel comprises a barrel body and a barrel lid. A round groove matched with the glue barrel is formed in the bottom of the charging barrel. A counter bore allowing the end of the glue barrel to be inserted into is formed in the center of the groove. The glue outlet communicates with the counter bore. The length of the glue barrel is set in the mode that after the glue barrel is inserted into the groove, the top face is just pressed by the barrel lid. The first air cylinder is arranged at the top of the charging barrel. The first air cylinder drives a sealing cover to squeeze the glue. The glue dispensing gun comprises a gun body. The second air cylinder used for squeezing the glue is arranged at the top of the gun body.

Owner:江门市光动力能源科技有限公司

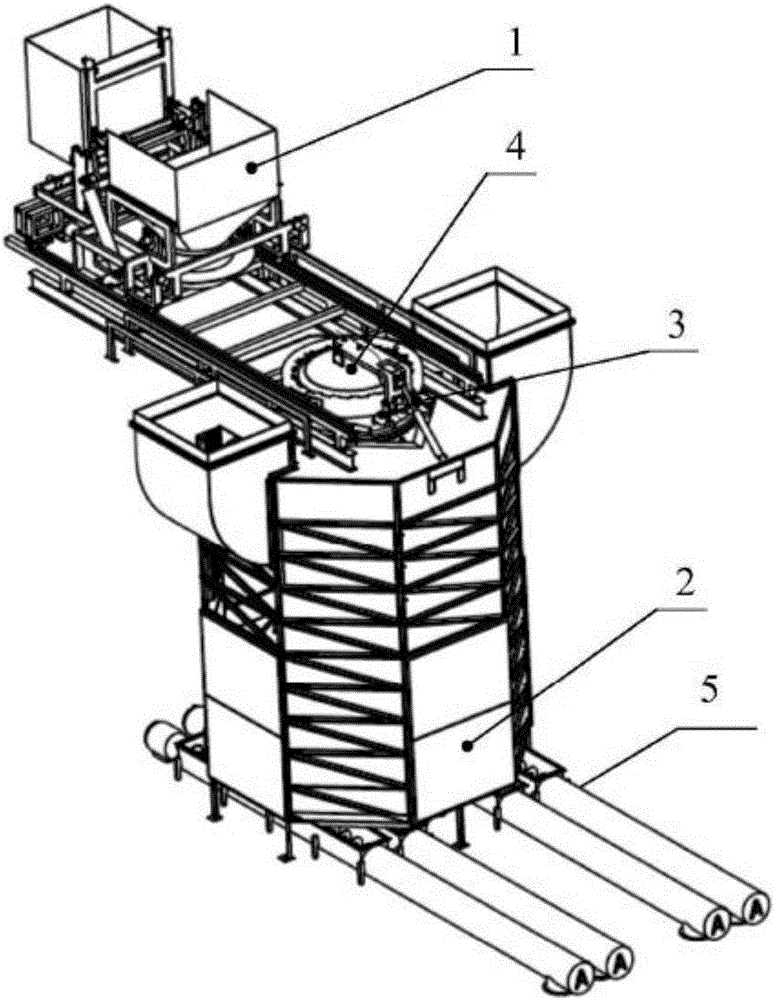

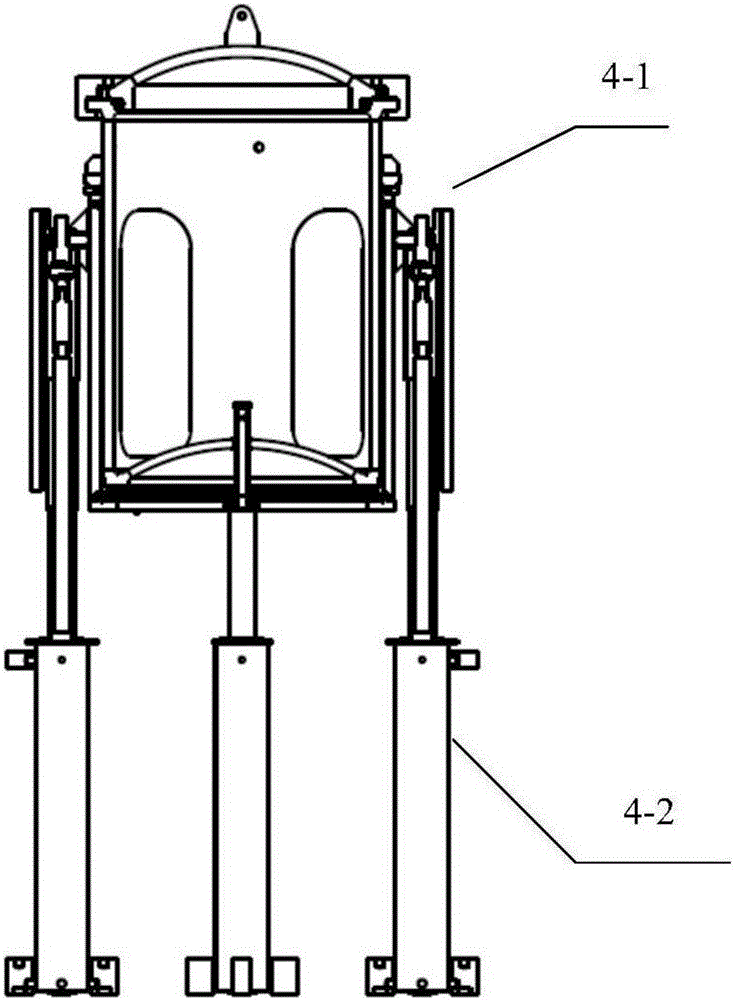

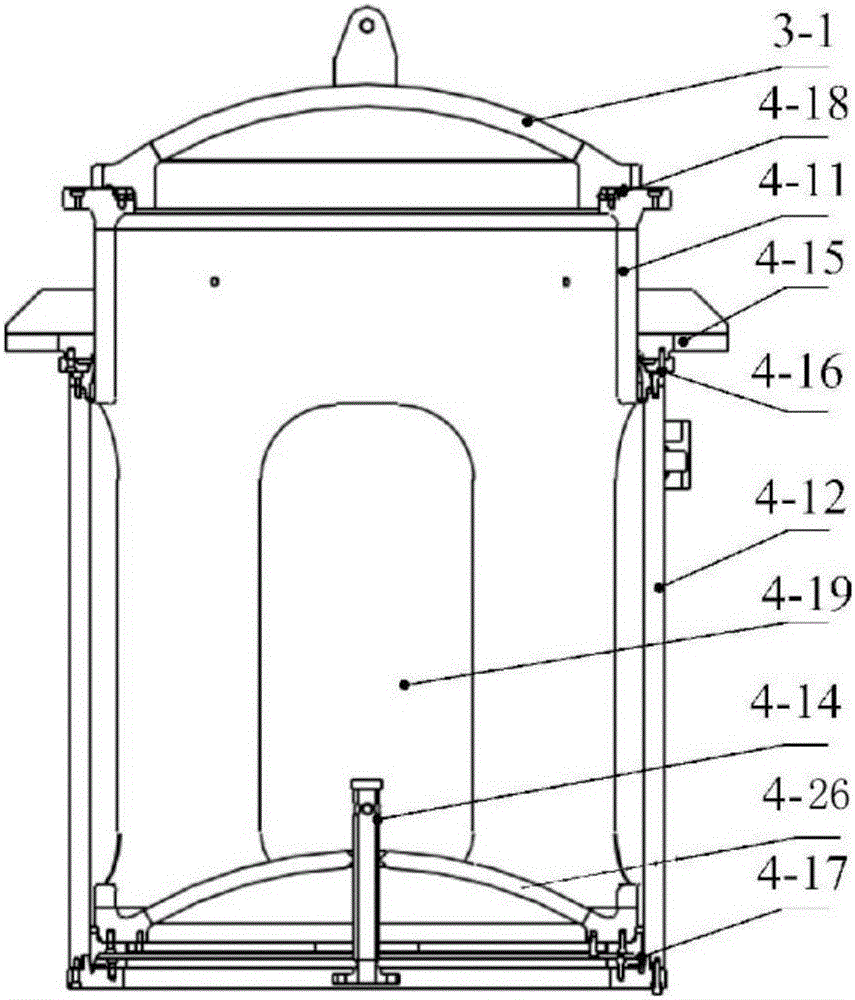

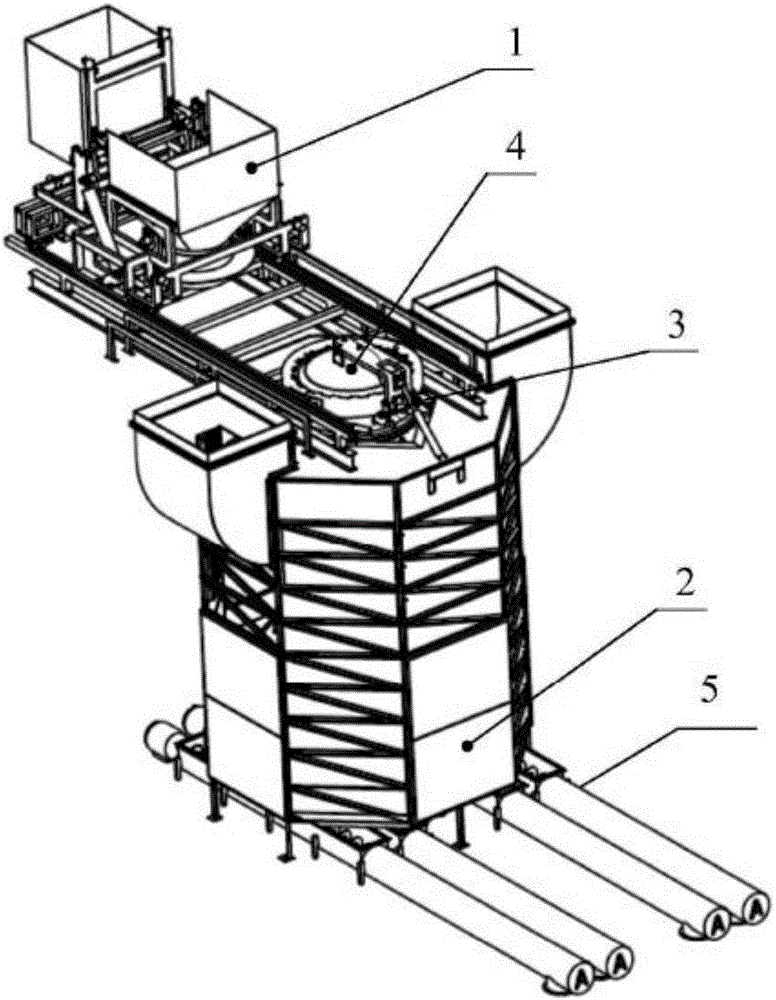

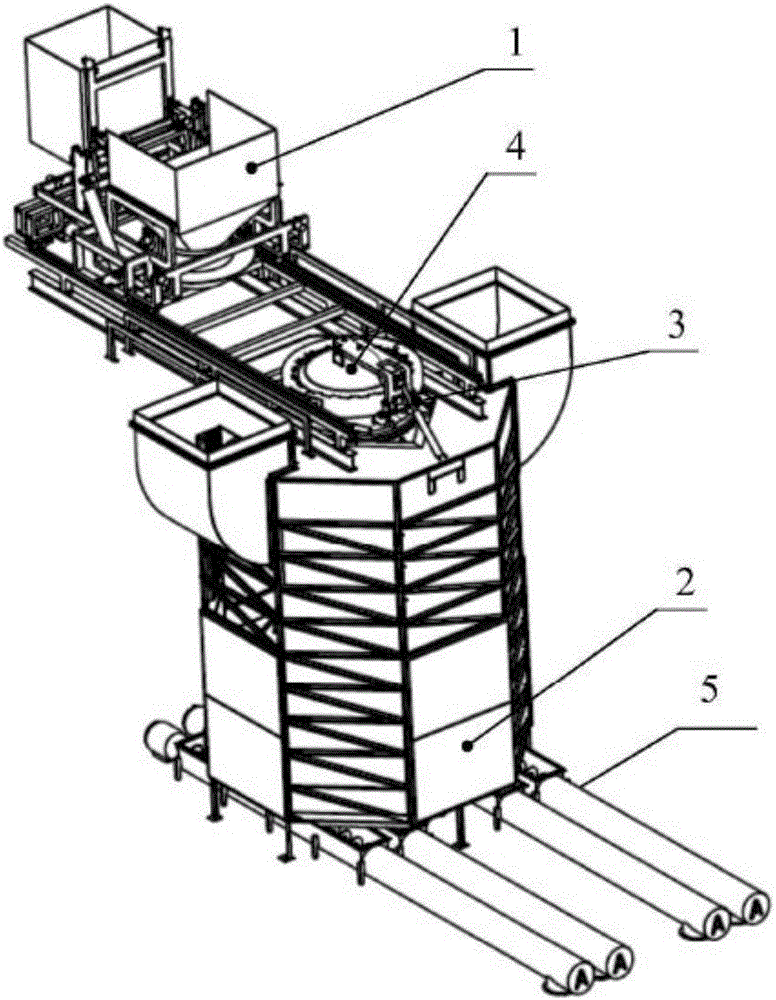

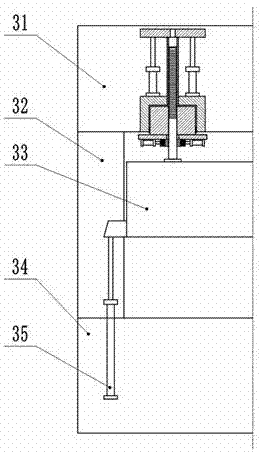

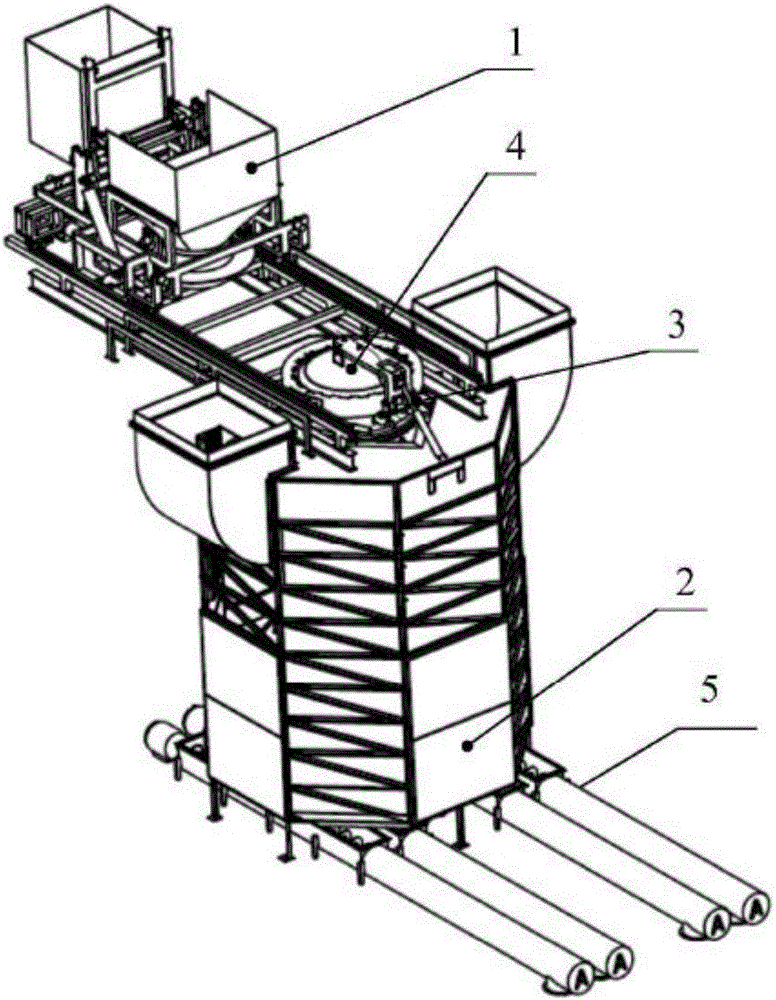

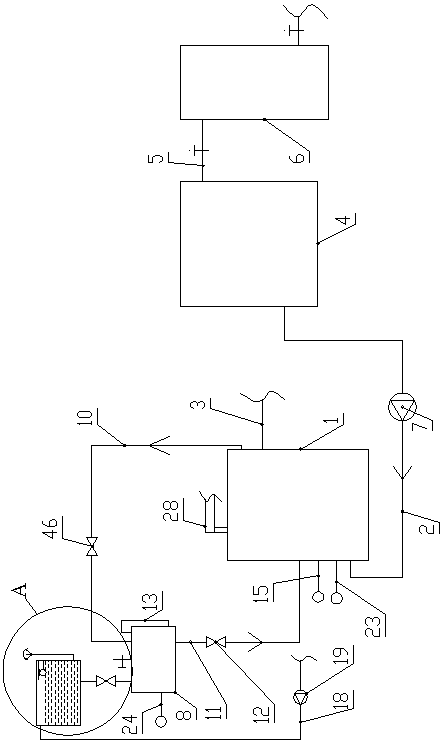

Pressurization and pressure relief system installed in integrated manner

InactiveCN106040394AImprove discharge efficiencyThe treatment effect is safe and reliableEngine sealsSolid waste disposalEngineeringMechanical engineering

The invention discloses a pressurization and pressure relief system installed in an integrated manner. A pressurization and pressure relief device is installed on an installing rack and comprises a separate cylinder barrel sealing device and a pneumatic opening mechanism. The separate cylinder barrel sealing device comprises an upper cylinder barrel and a lower cylinder barrel. The lower cylinder barrel is installed on the outer side of the upper cylinder barrel in a sleeving manner. The upper cylinder barrel comprises a steam valve port located in the bottom and discharging openings located in the side portion. The upper cylinder barrel is provided with installing lugs. The lower cylinder barrel is in sliding connection with the upper cylinder barrel. The lower cylinder barrel slides along a guide rail. A sliding block of the guide rail is connected to the installing lugs of the lower cylinder barrel in a screwed manner. The guide rail and the installing rack are welded. The installing lugs of the upper cylinder barrel and the installing rack are connected through bolts. The pneumatic opening mechanism is used for driving the lower cylinder barrel to slide up and down. The installing rack is installed in an integrated manner, the whole pressurization and pressure relief system is compact in structure and overcomes the defect that a traditional pressurization and pressure relief device occupies large space, and the production and use cost is reduced.

Owner:TIANZI ENVIRONMENTAL PROTECTION EQUIP MFG TIANJIN

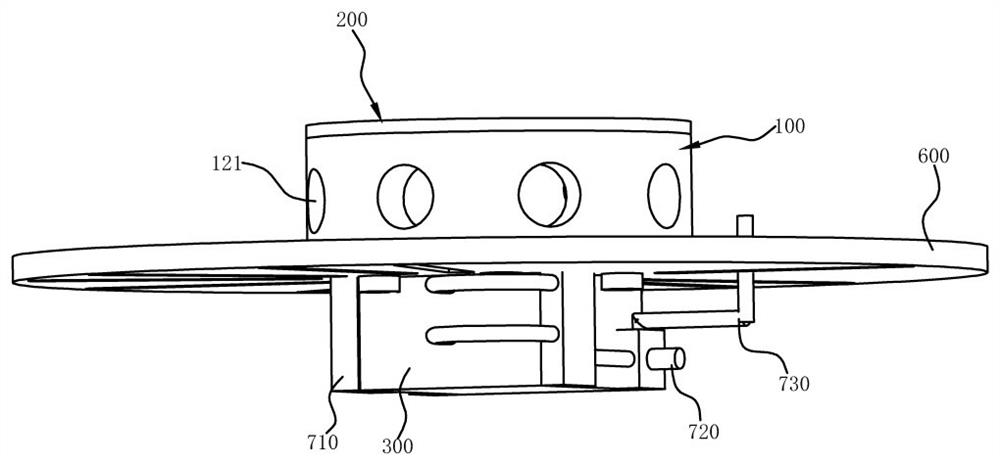

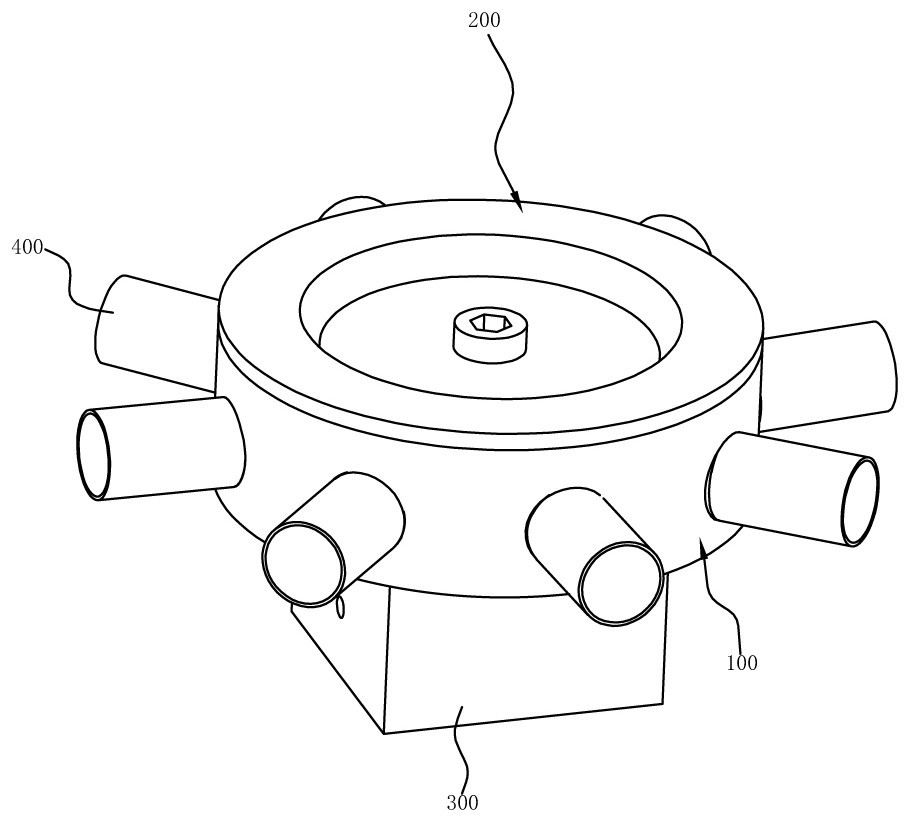

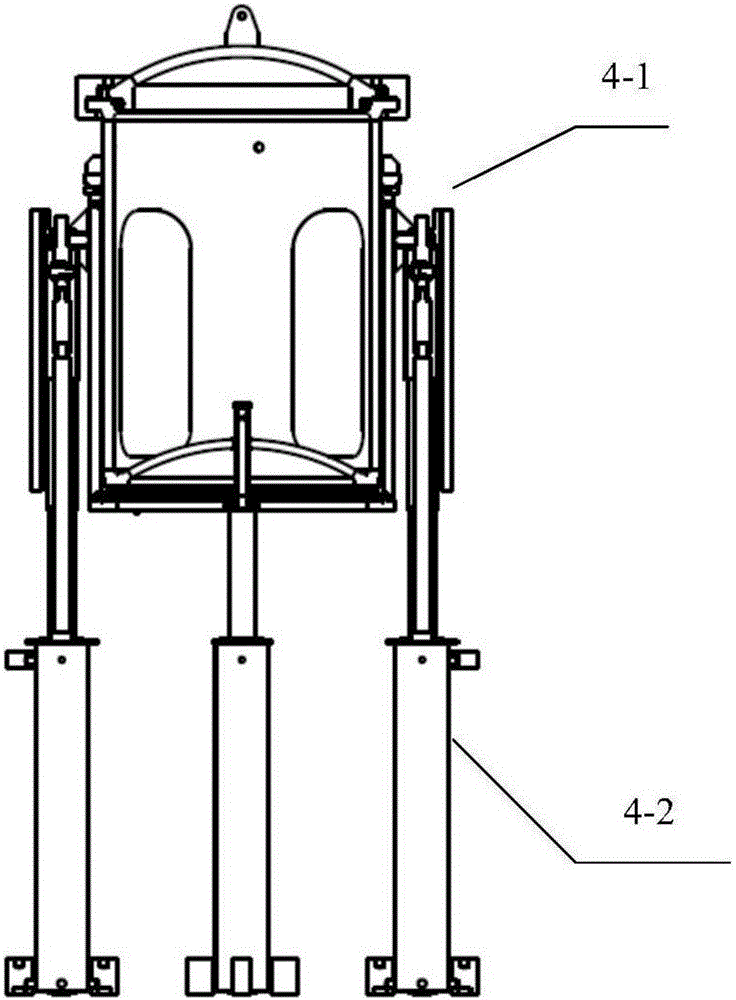

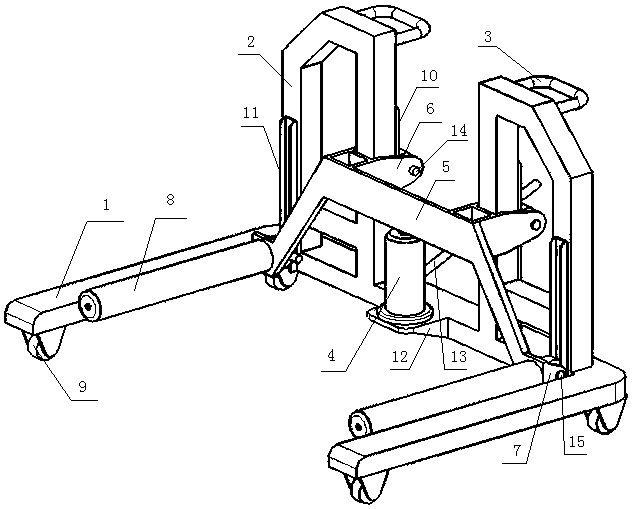

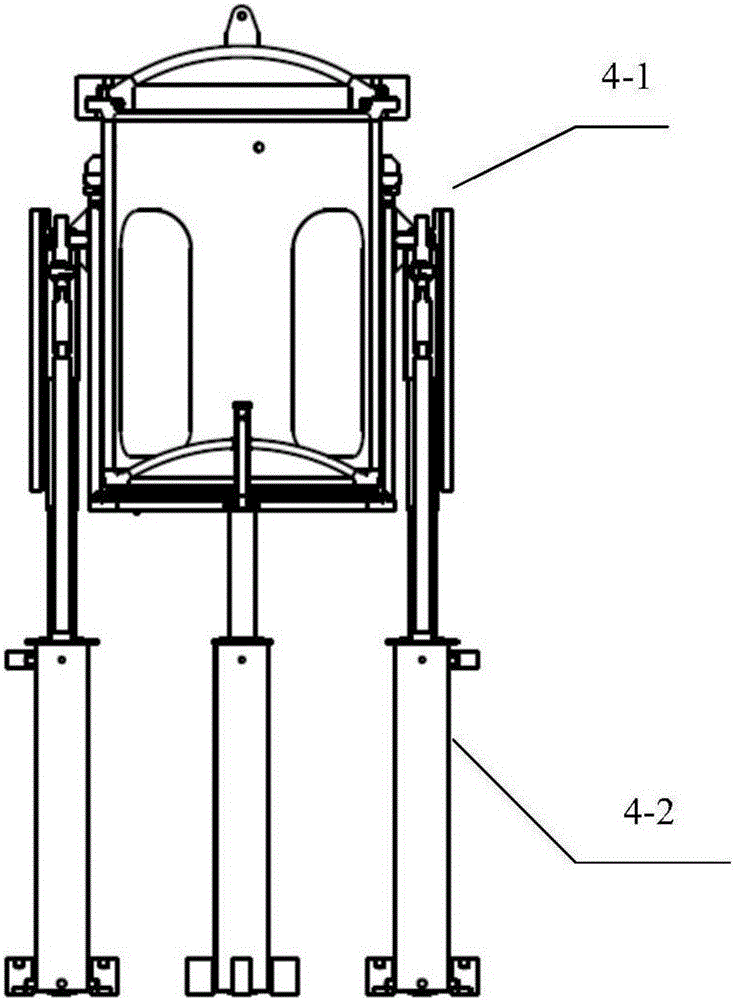

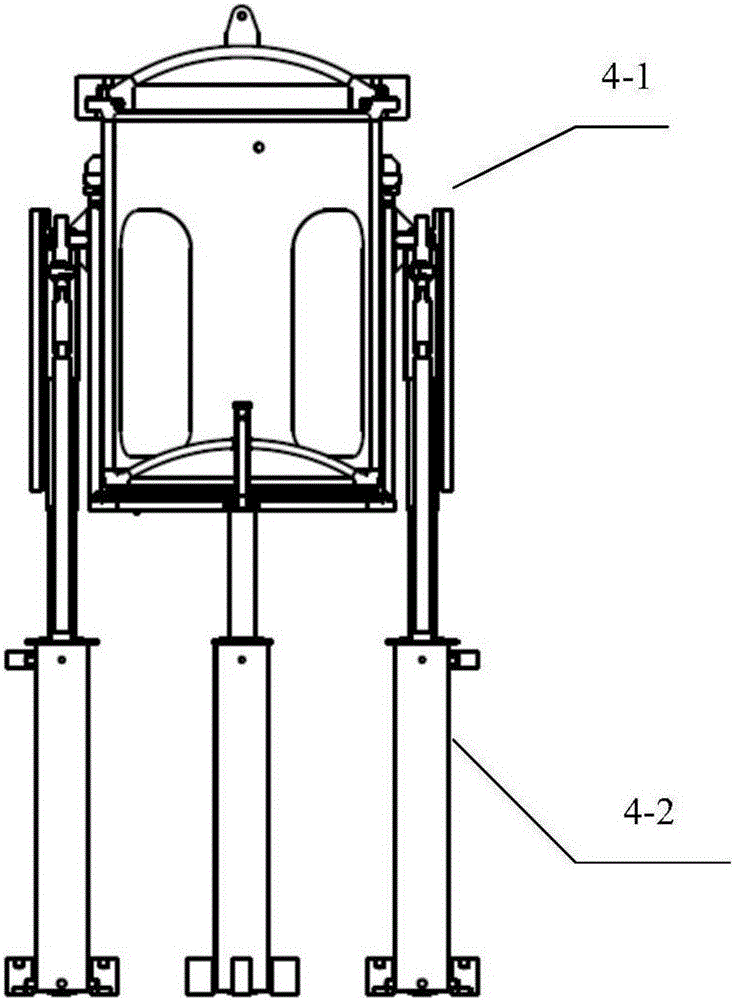

Transport plane wheel rapid dismounting and mounting device

PendingCN108284709AEasy to operate and control the lifting heightControl lift heightWheel mounting apparatusTyre repairingEngineeringHandrail

The invention discloses a transport plane wheel rapid dismounting and mounting device. The transport plane wheel rapid dismounting and mounting device comprises a main body frame and a lifting hydraulic wheel fork, the main body frame comprises a supporting frame, a connecting frame and an armrest, and the lifting hydraulic wheel fork comprises a hydraulic jack, a sliding support and rolling bars.The connecting frame is arranged at the upper end of the supporting frame, universal wheels are arranged at the lower end of the supporting frame, and the armrest is arranged on the connecting frame.Sliding rails are arranged on the inner side and the outer side of the connecting frame correspondingly, the connecting frame is connected with the sliding support through the sliding rails, and therolling bars are arranged on the lower sides of the two sides of the sliding support. A tray is arranged on the position, below the sliding support, of the inner side of the supporting frame, the hydraulic jack is arranged on the tray, and a hand-cranking rod is arranged on the hydraulic jack. According to the transport plane wheel rapid dismounting and mounting device, the dismounting and mounting time of a plane wheel is saved, and the problem that the waist of a person is hurt is effectively avoided.

Owner:AIR FORCE ENG UNIV OF PLA AIRCRAFT MAINTENACE MANAGEMENT SERGEANT SCHOOL

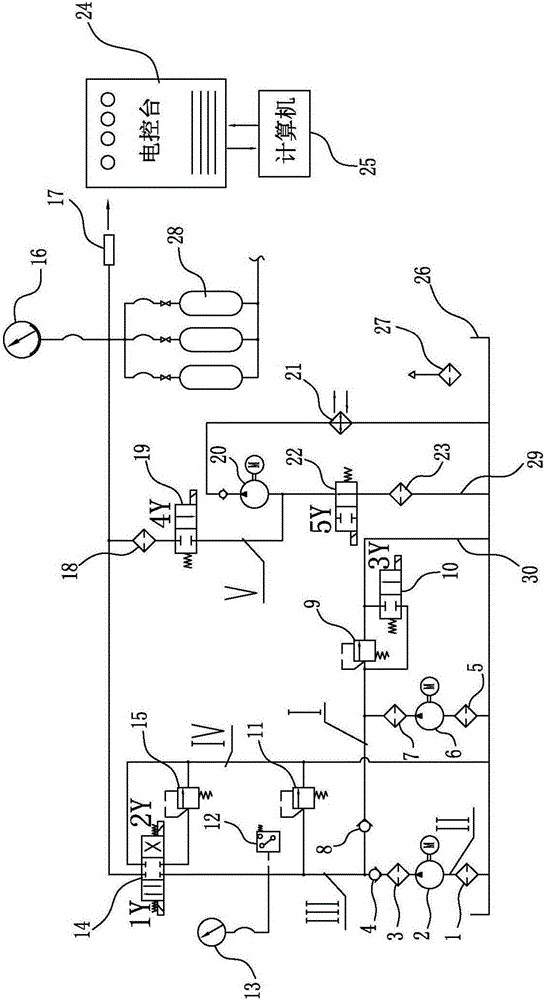

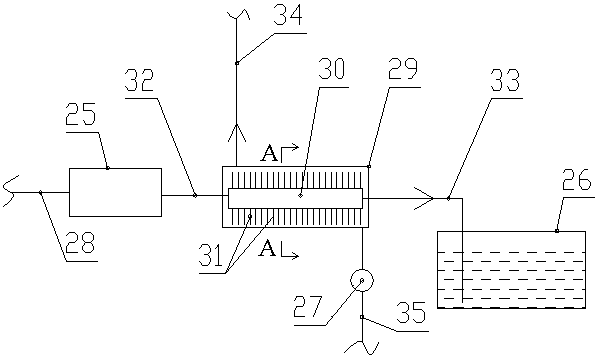

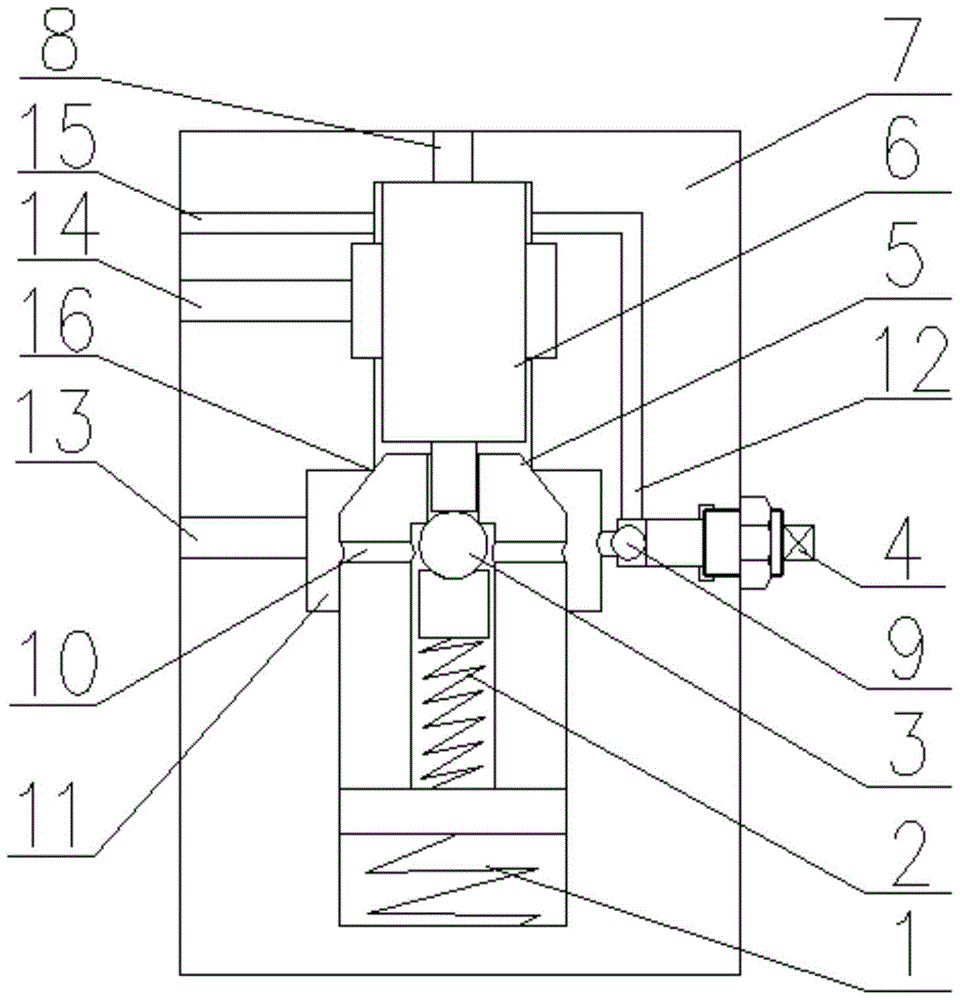

Energy accumulator fatigue test device and test method

ActiveCN106640847AEfficient Stress Fatigue TestFast pressure reliefFluid-pressure actuator testingTest efficiencyFuel tank

The invention relates to the technical field of energy accumulator fatigue tests, in particular to an energy accumulator fatigue test device and a test method. The device comprises a loading system and a pressure relieving system; the loading system includes at least two branched oil supply pipelines and a main oil supply pipeline; one ends of all the branched oil supply pipelines are communicated with an oil tank, and the other ends are connected with each other in parallel and communicated with one end of the main oil supply pipeline; the other end of the main oil supply pipeline is communicated with an energy accumulator; two branched oil supply pipelines are respectively provided with high-flow high-pressure oil pumps and low-flow ultrahigh-pressure oil pumps; the pressure relieving system is provided with an oil extracting pump and an oil extracting pipeline; the unloading time of the energy accumulator can be shortened; and the high-volume energy accumulator fatigue test efficiency is further improved. Through pressurizing an energy accumulator shell combination through a high-pressure oil pump motor set and an ultrahigh-pressure oil pump motor set, high-efficiency pressure fatigue tests of all nominal volume grade and design pressure grade energy accumulators in 0-70 MPa are realized.

Owner:HEFEI GENERAL MACHINERY RES INST

Pressure relief and noise reduction safety valve

InactiveCN102032372AEasy to useImprove comfortValve members for absorbing fluid energyEqualizing valvesEngineeringNoise reduction

The invention discloses a pressure relief and noise reduction safety valve, which comprises a valve body and a spool. An air inlet and air outlets are formed on the valve body; the air outlets are a plurality of vent holes; the spool is slidably arranged inside the valve body; and an elastic compaction piece for tightly pressing the spool to allow the spool to be in sealed fit with the air inlet is arranged between the spool and the valve body. The safety valve can guarantee normal use of an air reservoir, and reduces the noise of the air reservoir during pressure relief and improves the driving comfort of a locomotive driver.

Owner:LOVOL HEAVY IND CO LTD

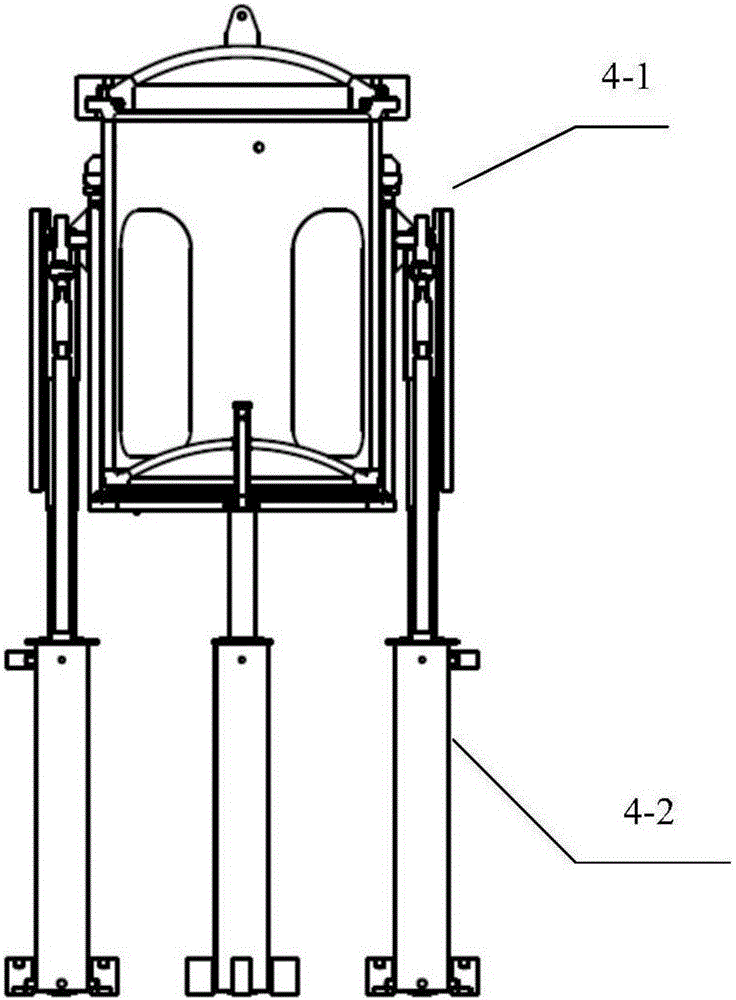

Pressurization and pressure relief device with high pressure relief speed

InactiveCN106040708AImprove discharge efficiencyThe treatment effect is safe and reliableEngine sealsSolid waste disposalDischarge efficiencyEngineering

The invention discloses a pressurization and pressure relief device with a high pressure relief speed. The pressurization and pressure relief device comprises a separate cylinder barrel sealing device and a pneumatic opening mechanism. The separate cylinder barrel sealing device comprises an upper cylinder barrel and a lower cylinder barrel. The lower cylinder barrel is of a cylinder structure with the two ends opened. The lower cylinder barrel is installed on the outer side of the upper cylinder barrel in a sleeving manner. The upper cylinder barrel comprises a steam valve port located in the bottom and discharging openings located in the side portion. An external steam pipeline is connected with the steam valve port. The lower cylinder barrel is in sliding connection with the upper cylinder barrel. The pneumatic opening mechanism is used for driving the lower cylinder barrel to slide up and down. A cylinder cover of a cover opening device covers the top end of the upper cylinder barrel. The pressurization and pressure relief device overcomes limitation of the net sectional area of a traditional method, multi-directional discharging is adopted, the exhausting and discharging area is increased, the discharging efficiency of the pressurization and pressure relief device is improved remarkably, the pressure relief speed is increased, the better exploding and smashing effect is achieved, the organic matter treatment effect is safer and more reliable, and the efficiency is higher.

Owner:TIANZI ENVIRONMENTAL PROTECTION EQUIP MFG TIANJIN

Underground pressure release valve and hydraulic shaping pipe column

ActiveCN112576221AImprove shaping efficiencyConvenient multi-levelWell/borehole valve arrangementsSealing/packingPressure riseStructural engineering

The invention discloses an underground pressure release valve and a hydraulic shaping pipe column. The underground pressure release valve comprises an outer sleeve, a valve seat, a valve element and apiston connecting piece, wherein a liquid outlet hole is formed in the outer sleeve, the valve seat is fixed in the outer sleeve and is in sealing fit with the outer sleeve, a pressurizing channel and a pressure release channel are formed in the valve seat, the piston connecting piece can move downwards along with a piston of a hydraulic booster when pressurizing the interior of the outer sleeve,a transmission relation is established between the piston connecting piece and the valve element when the piston connecting piece moves downwards by a certain distance, and the valve element is disengaged from the valve seat to communicate the pressure relief channel. According to the underground pressure release valve, when the piston connecting piece descends to a certain position, the valve element can be automatically driven to be disengaged from the valve seat, the pressure release channel is connected, then the hydraulic shaping column automatically releases pressure, the whole pressurerelease process is conducted underground, frequent pressure rising and releasing on the ground manually are not needed, the pressure release speed is high, the process is safe and reliable, manpowerand material resources can be saved, and pipe column shaping efficiency can be improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

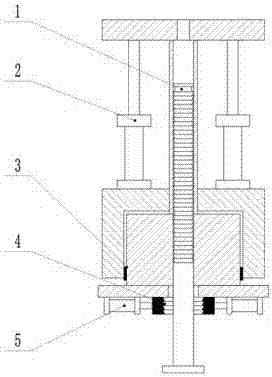

Rapid suppressing device of high-speed hydraulic stamping press

The invention discloses a rapid suppressing device of a high-speed hydraulic stamping press. The rapid suppressing device of the high-speed hydraulic stamping press mainly comprises a force transfer bar, plunger return cylinders, a short-stroke plunger cylinder, force transfer clamp jaws and drivers. The rapid suppressing device has a stroke switching function and a short-stroke rapid pressure buildup function, can be used as a suppressing actuator of the high-speed hydraulic stamping press to achieve long-stroke high-speed movement of the hydraulic stamping pressure and rapid pressure buildupduring workpiece stamping; and meanwhile, the installed power of the hydraulic stamping press is reduced, and energy efficiency is optimized.

Owner:NANTONG FORGING EQUIP

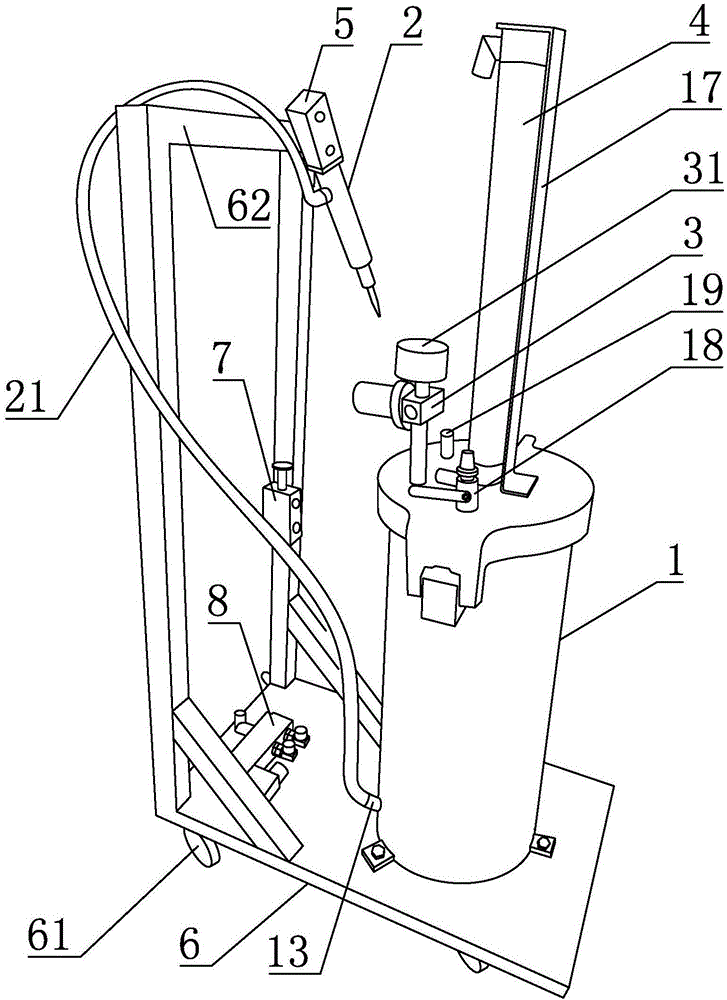

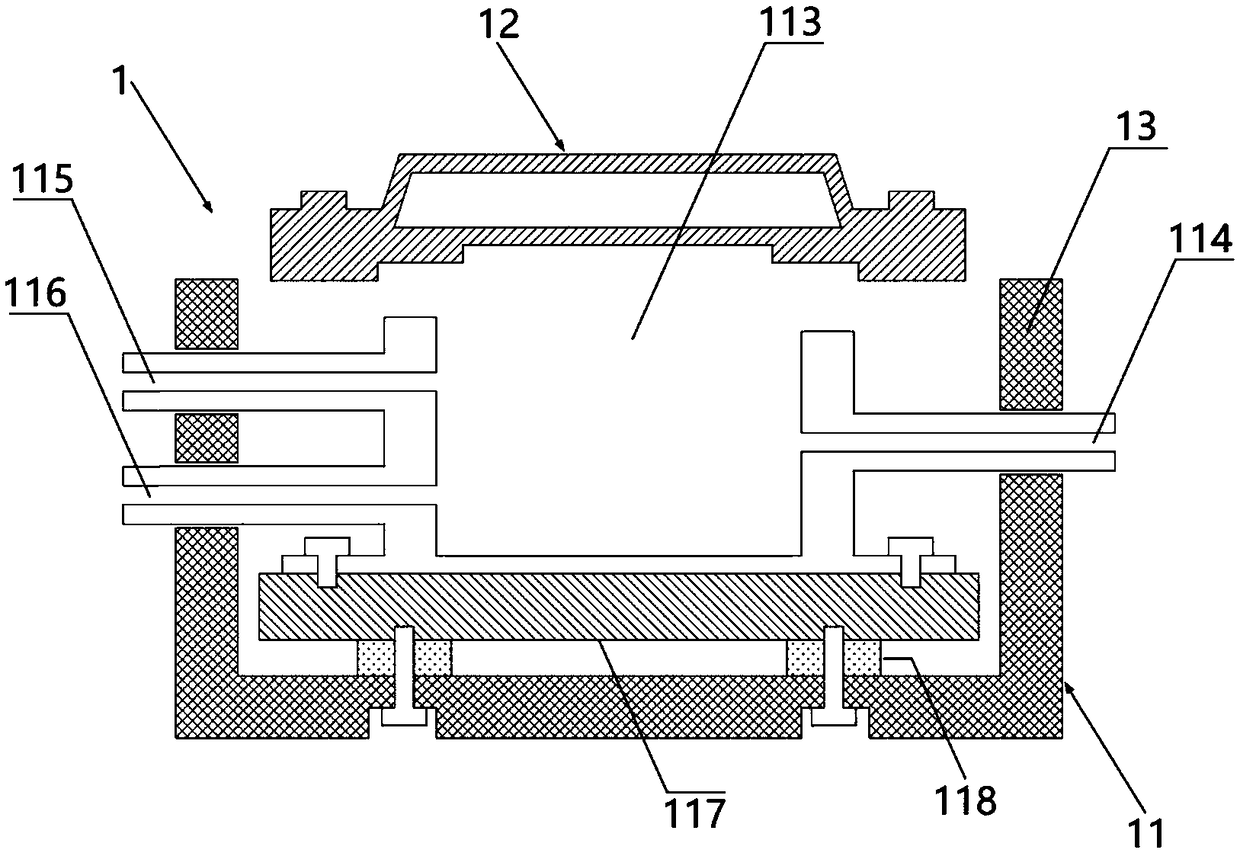

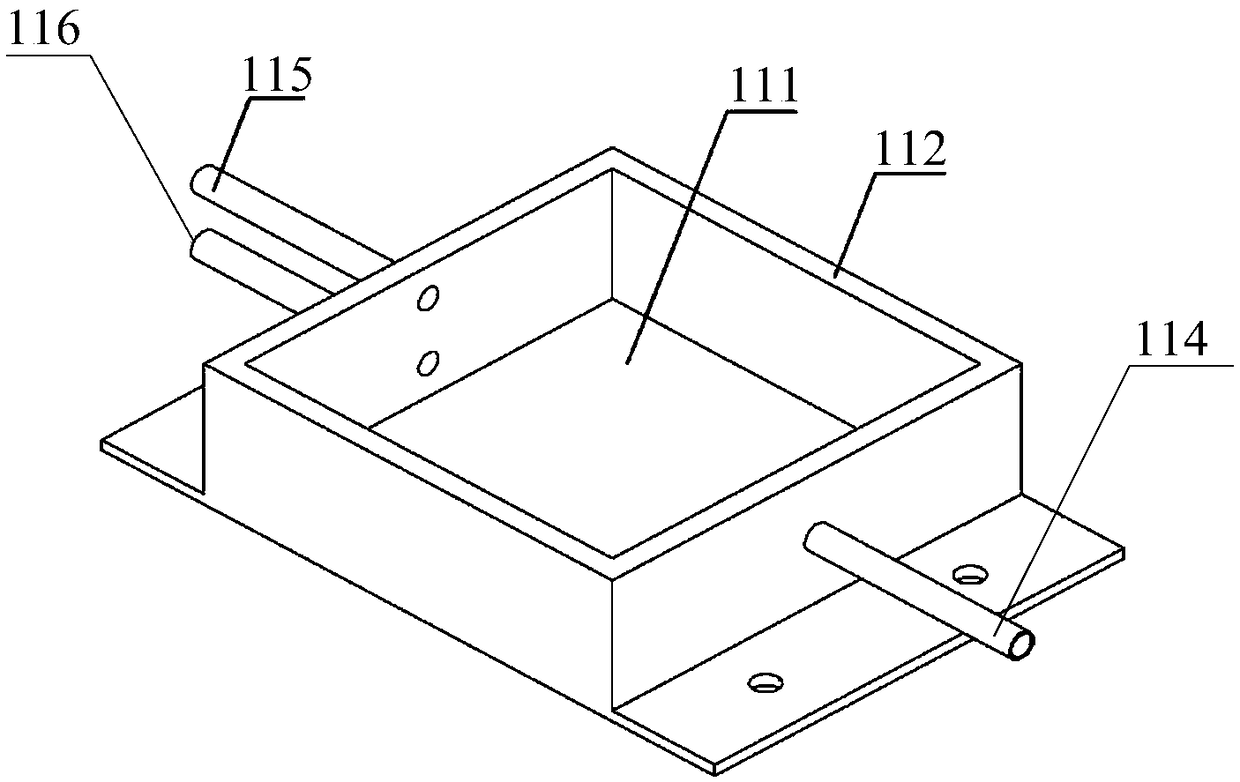

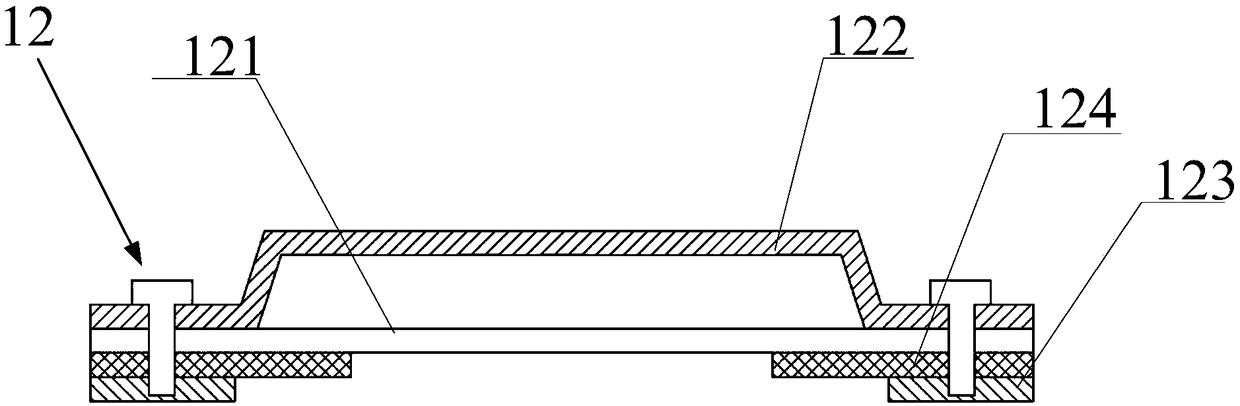

Negative pressure controllable atmosphere welding system

ActiveCN108994411AAvoid the problems of low heating and cooling rate and long welding timeMeet welding needsMetal working apparatusSoldering auxillary devicesAtmospherePetroleum engineering

The invention discloses a negative pressure controllable atmosphere welding system. The negative pressure controllable atmosphere welding system comprises a preheating table, a welding device, a cooling table and a program control system, wherein the preheating table is used for preheating to-be-welded products, and the welding device is used for welding the to-be-welded products; the cooling table is used for cooling the welded finished products; the program control system is used for controlling the welding device to draw negative pressure and introduce inert gas; and the welding device is connected with the program control system. The preheating table, the welding device and the cooling table are independently arranged, and the welding device can be quickly opened and closed according to use requirements, so that the welded process products can be rapidly switched between the preheating table, the welding device and the cooling table, the problems that in the prior art, because thepreheating table, the welding device and the cooling table are arranged into a whole, the cooling rate is low and the welding time is long are solved; and therefore, the negative-pressure controllableatmosphere welding system can achieve low-hole-rate welding of the products under the condition that the welding time is not remarkably increased, and the welding requirement of the products is met when the welding time is met.

Owner:BEIJING SUPLET

Upper cylinder barrel with reliable sealing performance

InactiveCN106040386AImprove discharge efficiencyThe treatment effect is safe and reliableEngine sealsSolid waste disposalDischarge efficiencyTherapeutic effect

Owner:TIANZI ENVIRONMENTAL PROTECTION EQUIP MFG TIANJIN

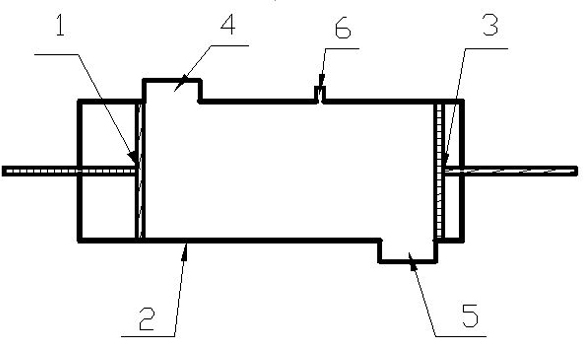

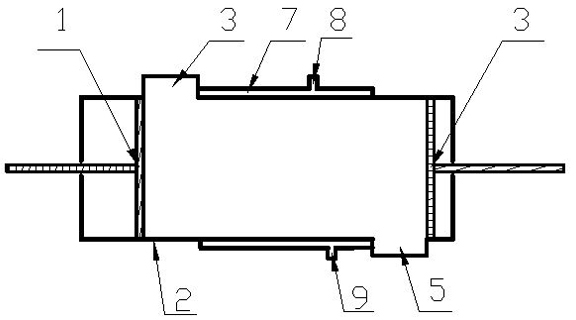

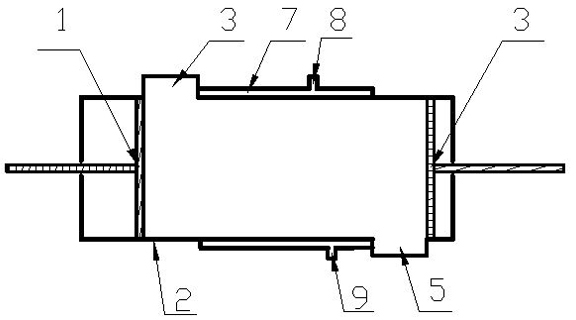

Timber internal micro blasting device

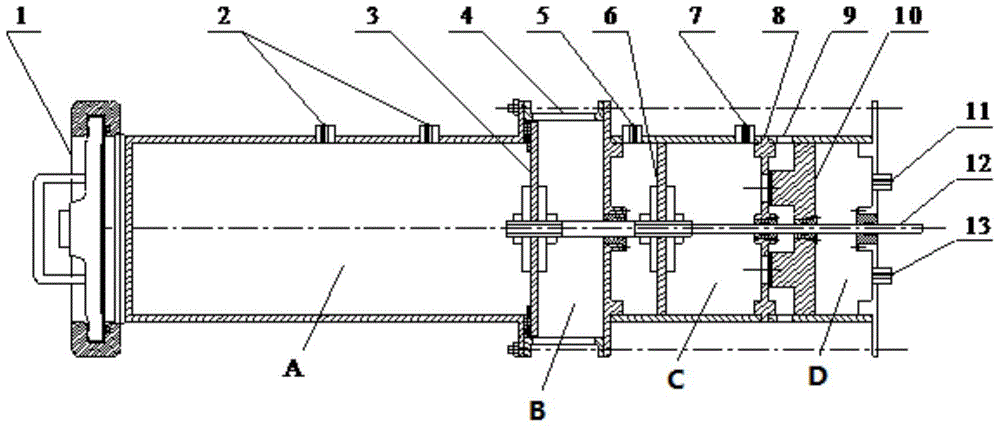

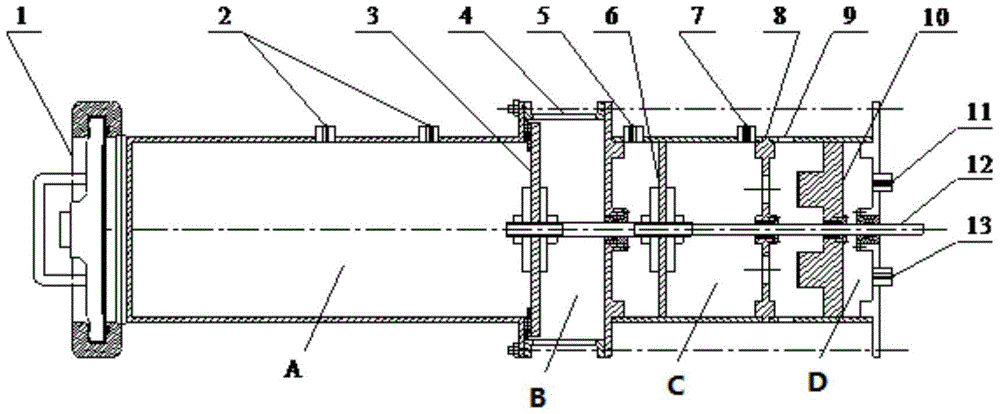

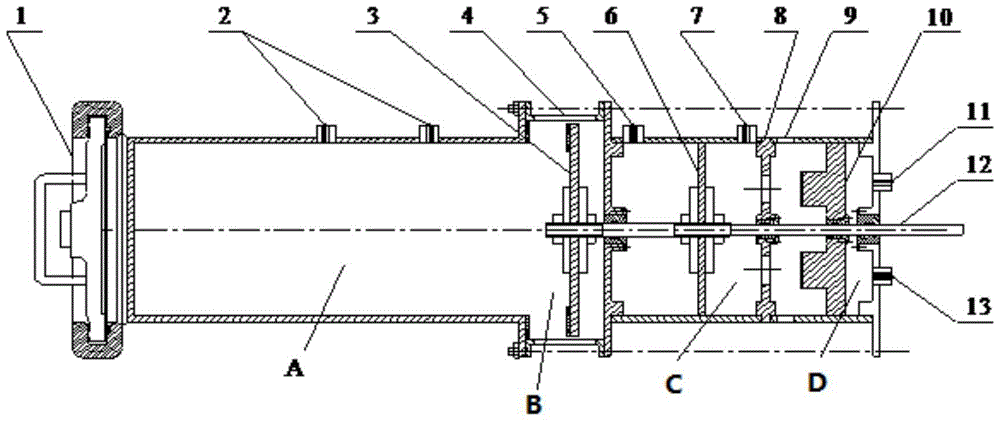

InactiveCN104690791BSmooth motionImprove blasting effectPressure wood treatmentWood treatment detailsEngineeringHigh pressure

The invention relates to a wood interior micro-blasting device, which comprises a pressure relief port equipped high pressure cylinder (A) for accommodating wood and a piston cylinder (C). The device is characterized in that: the high pressure cylinder (A) and the piston cylinder (C) are connected by a pressure relief cylinder (B), the pressure relief cylinder (B) wall near the pressure relief port is provided with an exhaust hole (4), the pressure relief cylinder (B) is internally provided with a cover plate (3) able to seal and open the pressure relief port; and the piston rod of the piston cylinder (C) stretches into the pressure relief cylinder (B) and is in fixed connection with the cover plate (3). As the high pressure cylinder and the piston cylinder are connected by the pressure relief cylinder for pressure relief, and the pressure relief cylinder is internally provided with the cover plate able to seal and open the pressure relief port, during pressure relief, the cover plate moves and is applied with a pushing force by the piston rod of the piston cylinder, the pressure relief speed is fast, the piston movement is stable, and the blasting effect is good.

Owner:BEIJING FORESTRY UNIVERSITY

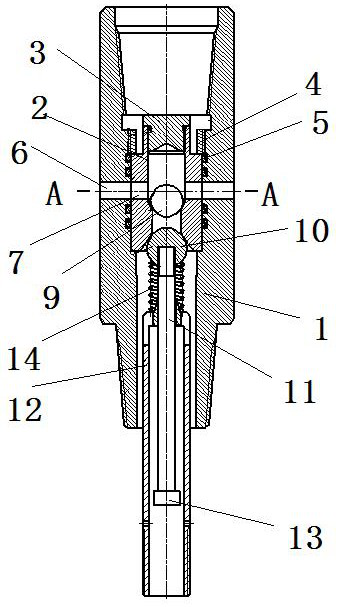

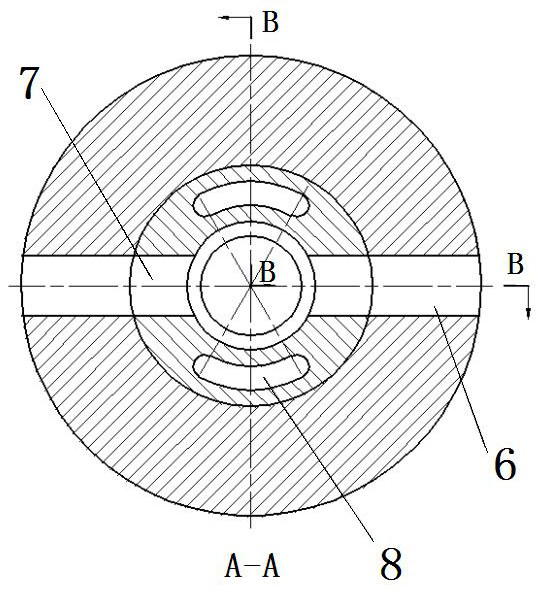

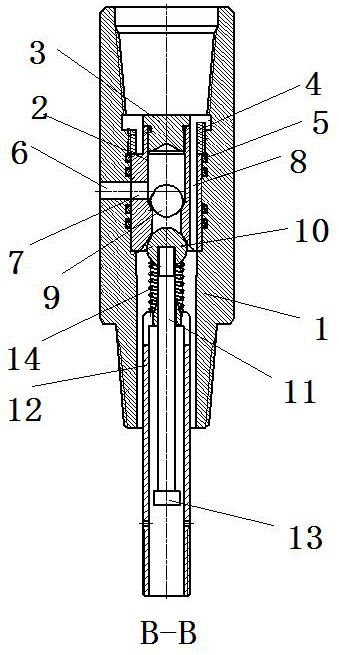

Quick-opening valve for steam explosion device

ActiveCN103075524BFast pressure reliefExtended service lifeOperating means/releasing devices for valvesLift valveEngineeringElectromagnetic valve

The invention provides a quick-opening valve for a steam explosion device. The invention relates to a valve, in particular to a gate valve used for a steam explosion machine. The invention aims at providing a quick-opening valve for a steam explosion device, which is suitable for the steam explosion device, is simple in structure and can realize quick opening of the valve. The quick-opening valve for the steam explosion device comprises a seal disc (1) provided with a valve hole (11) in the middle part, at least two slide bars (2) which are parallel to each other, a valve body plate (3) capable of sliding along the slide bars, a valve body (31) and a valve seat plate (4), wherein a buffer device is arranged on the end surface, close to the valve body plate, of the valve seat plate; the other end surface of the valve seat plate is fixedly provided with an oil cylinder body (5); a piston rod (52) passes through a through hole (41) and is fixedly connected with the valve body plate; the oil cylinder body is internally provided with a pressure spring (53) and / or a tension spring (54); one end of the oil cylinder body is provided with a vent hole (57), and the other end of the oil cylinder body is provided with a first oil through hole (55) and a second oil through hole (56) which have different sizes; and the quick-opening valve also comprises two electromagnetic valves which are respectively communicated with the two oil through holes.

Owner:李楠 +1

A desktop low-melting point metal three-dimensional printer nozzle

ActiveCN105965021BHigh precisionReasonable structureAdditive manufacturing apparatusInternal pressureSpray nozzle

The invention belongs to the field of equipment of the three-dimensional printing technology, and particularly relates to a spray nozzle of a tabletop low-melting-point metal three-dimensional printer. The spray nozzle comprises a melting material feeding device, a spray nozzle body, a melting material discharging device, a piston piece, a gas pressure controller, a gas pressure meter and a heating piece; the spray nozzle body is used for storing and spraying out melting materials, a gas pressure bin and a melting material bin are arranged in a spray nozzle shell, the gas pressure bin and the melting material bin are separated through the piston piece, and the gas pressure bin is connected with the gas pressure controller and is used for adjusting gas pressure in the gas pressure bin and gas pressure in the melting material bin; the gas pressure meter is arranged on the gas pressure bin, and pressure value in the gas pressure bin is displayed; and low-melting-point metal is adopted to serve as a printing material, the structure is novel, the gas pressure bin is additionally arranged in the spray nozzle, the pressure in the melting material bin is indirectly controlled through the gas pressure bin, the pressure value inside the melting material bin can be visually reflected, control precision is high, the pressure relief speed is high, the phenomena of excessive printing and material dragging are avoided, the precision of finished products is high, the unnecessary technology is removed, and the printing efficiency is improved.

Owner:YUNNAN MARVEL TECH CO LTD

Boiler anti-burning dry safe operation method

ActiveCN106322349BPrevent burnoutProtect from being burned dryFluid heatersSteam boilersWater storageEngineering

Owner:河南省锅炉压力容器安全检测研究院

Novel rapid discharging valve applied to large foaming machine

The invention discloses a novel rapid discharging valve applied to a large foaming machine. Pressure guide oil enters a first oil cavity and a second oil cavity of a pilot valve body through a pilot pressure guide channel, a pilot valve piston moves upwards under the pushing effect of the pressure guide oil till a channel between an oil passing groove and a first valve element hole is completely sealed and blocked, at the moment, a rapid hydraulic oil discharging channel is in a closed state, when the rapid hydraulic oil discharging channel is opened, the pressure guide oil in the first oil cavity and the second oil cavity is discharged through the pilot pressure guide channel, at the moment, the pilot valve piston moves downwards under the action of a first spring, the channel between theoil passing groove and the first valve element hole is rapidly opened, the hydraulic oil, located above a main piston mechanism, in a vertical oil cavity is rapidly discharged through the rapid hydraulic oil discharging channel, and therefore the ascending speed of the main piston mechanism is effectively increased. The novel rapid discharging valve applied to the large foaming machine has the characteristics of being novel in structure, higher in pressure relief speed and higher in practicability.

Owner:晋江市火炬油压机械有限公司

A Balanced Two-position Three-way Fuel Injection Valve

ActiveCN110242460BReduce shockSmall preloadFluid pressure injection controlMachines/enginesControl valvesPiston

The invention is a balanced two-position three-way fuel injection valve. The injection valve includes an armature, an armature rod, a control valve seat, an injector body, a control piston, an electromagnet and an electromagnet spring; the control valve seat is pressed into the cavity on the upper part of the injector body through the control valve seat fixing nut ; There is an electromagnet middle hole in the center of the electromagnet; a sealing cone is arranged at the middle hole of the upper end surface of the control valve seat; the electromagnet spring is placed in the electromagnet middle hole, and the armature is pressed tightly on the sealing cone surface. When pressed on the control valve seat, the sealing cone surface cooperates with the lower cone surface of the armature to form a line seal; the armature and the armature rod are integrated structure, and the armature rod extends into the middle hole of the control valve seat; the middle hole of the injector body The bore is provided with an axially movable control piston. The invention can reduce the dynamic oil return amount and improve the utilization rate of high-pressure oil; at the same time, it can reduce the spring preload of the control valve, improve the response, reduce the impact on the sealing element, and meet the injection requirement of higher pressure.

Owner:FAW JIEFANG AUTOMOTIVE CO

Gas and gas appliance valve pressure relief device

ActiveCN101514914BAccurately open the valve in placeIncreased sensitivityVolumetric apparatus damage preventionEngineeringHigh pressure

The invention discloses a gas and gas appliance valve pressure relief device. A pressure relief body is arranged in a valve body, a pressure relief rubber mat is pressed on the pressure relief body, a tray and a pressure plate are arranged on the rubber mat, and a pressure spring is arranged between the pressure plate and the tray. As the pressure relief device is arranged in the valve body, whenthe pressure relief device is driven, a transfer torque screw rod is subjected to small rotary torque, the pressure relief rubber mat on the pressure relief body is immediately separated from the plane of a gas port of the tray to generate a gap, and the gap expands continually; the high-pressure gas in a gas inlet box quickly enters a lower-pressure lateral box along three arc merohedral groovesof the pressure relief body, and instantly the two boxes have equal pressure; and the pressure spring resets the tray to the pressure relief body, the tray does not bear the pressure any longer, a valve port rubber mat on the tray is separated from a valve port under the dead weight of the tray and the valve opening rotation of the transfer torque screw rod continuously subjected to the torque, and the valve is accurately opened. The device has the advantages of good sensitivity, quick pressure relief speed and stable work, and is applicable to being arranged at a gas outlet end and a valve.

Owner:LIAONING SCALER TECH CO LTD

A combined relief valve

ActiveCN104712798BFast pressure reliefImprove work efficiencyEqualizing valvesSafety valvesWork cyclePetroleum engineering

The invention provides a combined pressure relief valve, which includes a valve core, a manual pressure relief valve, a main oil passage, an auxiliary oil passage, a spring seat and other structures, which can realize primary and secondary pressure relief. Under special circumstances such as power failure, manual pressure relief can be realized. By implementing the invention, when the main oil cylinder of the hydraulic machine releases pressure, the pressure release speed is accelerated, the working cycle is shortened, the valve volume is reduced, and the operation and maintenance are convenient.

Owner:天津帝广机电设备有限公司

Upper cylinder barrel device

InactiveCN106040713AEasy to installEasy maintenanceEngine sealsSolid waste disposalDischarge efficiencyTherapeutic effect

The invention discloses an upper cylinder barrel device. The upper cylinder barrel is a barrel which is open on the upper end and closed on the bottom. The upper cylinder barrel comprises a steam valve port on the bottom and discharge ports on the side, an external steam pipeline is connected with the steam valve port and is used for injecting high-temperature high-pressure steam into the upper cylinder barrel; the upper cylinder barrel is provided with mounting support lugs, the mounting support lugs are connected with a mounting frame through bolts. By using the upper cylinder barrel, the limitation of the effective section area of a traditional method is conquered and a multi-directional discharging is adopted, so that the discharge area of gas and materials is increased, the discharging efficiency of a pressurizing pressure relief device is obviously increased, the pressure relief speed is increased, the good explosion effect is achieved, the organic matter treatment effect is safer and more reliable, and the efficiency is higher.

Owner:TIANZI ENVIRONMENTAL PROTECTION EQUIP MFG TIANJIN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com