Novel rapid discharging valve applied to large foaming machine

A foaming machine, a new type of technology, applied in the direction of mechanical equipment, fluid pressure actuators, servo motor components, etc., can solve the problem of affecting the working efficiency of the hydraulic system of the large foaming machine, the slow pressure relief speed, and the impact of the large foaming machine Foaming quality and other issues, to achieve the effect of novel structure, fast pressure relief, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

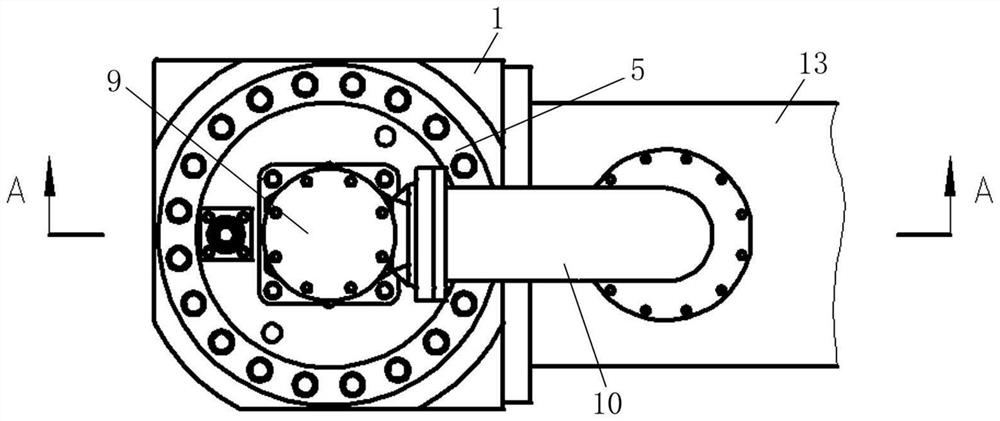

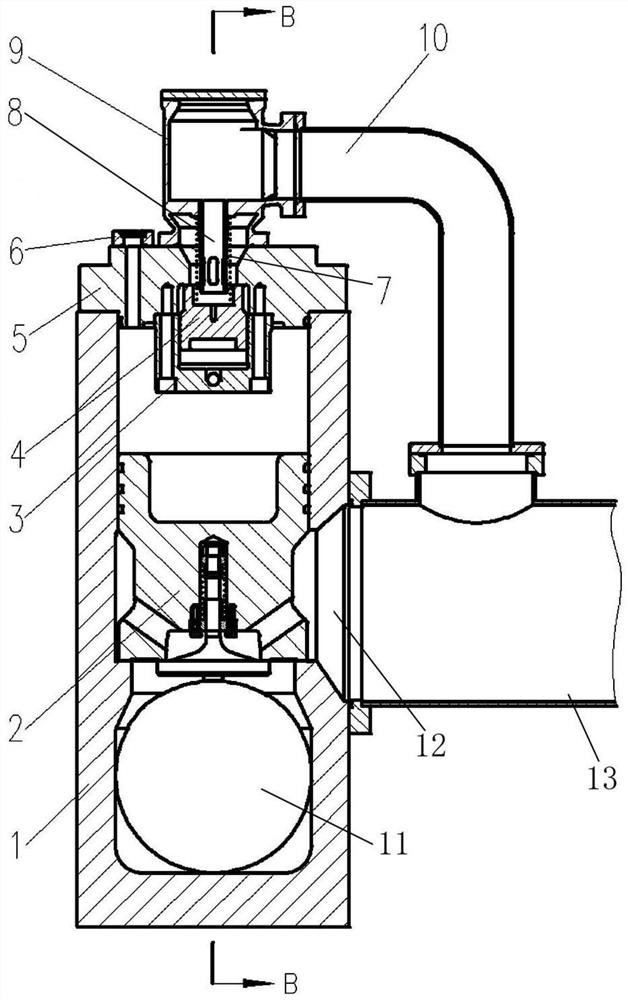

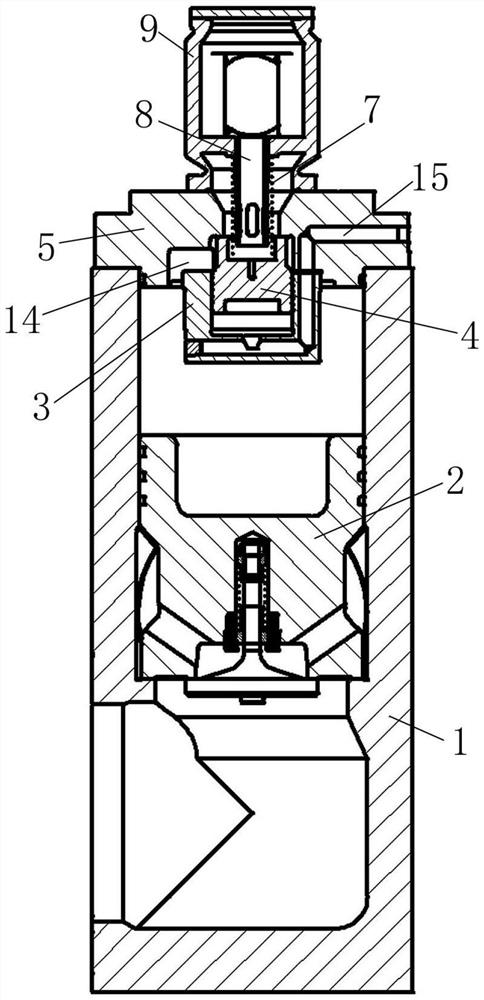

[0033] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a new type of quick discharge valve used in a large foaming machine is composed of a vertical main valve body 1, a main piston mechanism 2, a pilot valve body 3, a pilot valve piston 4, a valve cover 5, and a main valve plus The pressure flange 6, the spring, the tee flange 9, the oil return pipe 10, and the vertical core pipe 8 are characterized in that,

[0034] The lower end of the front side of the vertical main valve body 1 is integrally formed with the first oil port 11 connected to the main oil cylinder, the lower end of the right side of the vertical main valve body 1 is integrally formed with the second oil port 12, and a pipe of the horizontal oil pipe 13 One end communicates with the second oil port 12, and the other end of the transverse oil pipe 13 communicates with the oil tank;

[0035] The inside of the vertical main valve body 1 is integrally formed with a vertical oil chamber, the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com