Electromagnetic pilot-operated diaphragm valve

A pilot-operated, diaphragm valve technology, applied in the direction of diaphragm valve, diaphragm, valve details, etc., can solve the problems of high minimum opening water pressure, easy water hammer phenomenon, slow water switching speed, etc., to achieve volume reduction, small vibration, The effect of increasing the pressure release speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

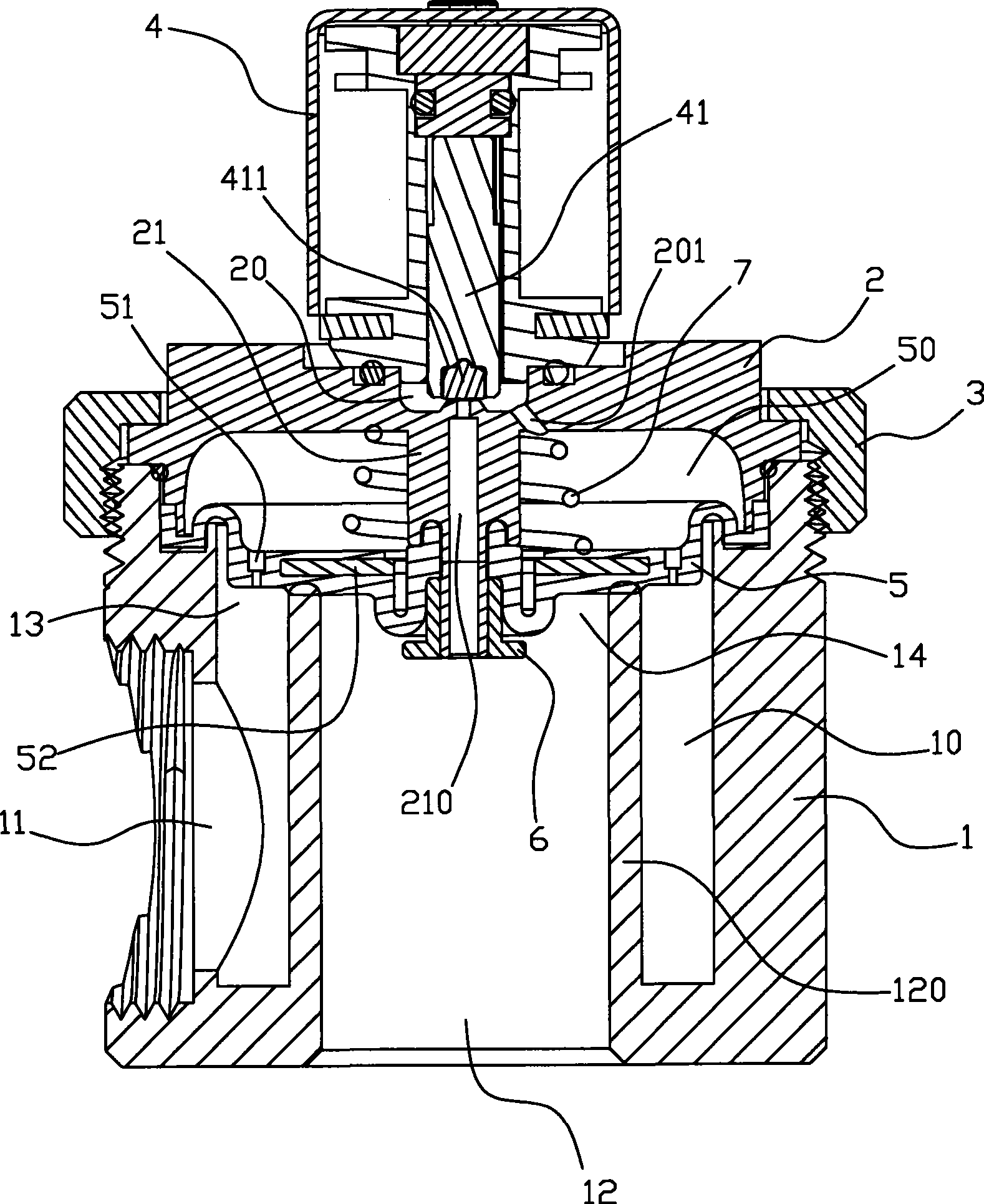

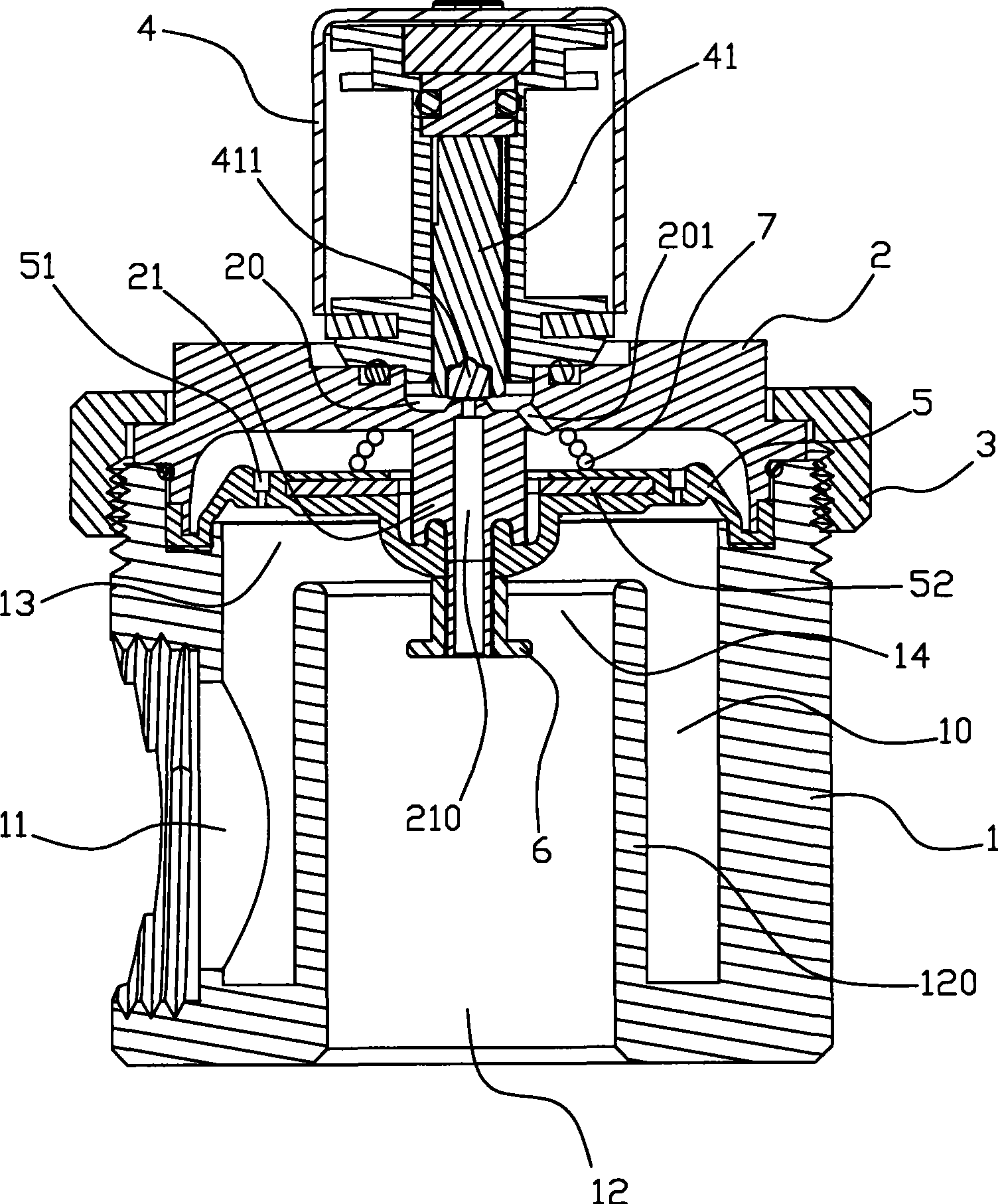

[0020] Solenoid pilot operated diaphragm valve, see figure 1 , its main structure includes valve body 1, valve cover 2, gland 3, solenoid valve 4, diaphragm 5, nut 6 and spring 7. The valve body 1 is provided with a valve chamber 10 and a water inlet 11, a water outlet 12, a control port 13 and a water outlet 14 communicating with the valve chamber. The central axes of the water outlet 12 and the control port are on the same straight line. The central axis of the water outlet 11 is perpendicular to the central axis of the water outlet 12 and the control port. The peripheral edge of the water outlet 12 protrudes into the valve cavity 10 to form a ring wall 120, and the inner end of the ring wall 120 forms the water outlet 14. It can be seen that the water outlet 14 is located between the water inlet 11 and the water outlet 12. , the on-off of the water port 14 can control the on-off of the passage between the water inlet 11 and the water outlet 12 .

[0021] The bonnet 2 is ...

Embodiment 2

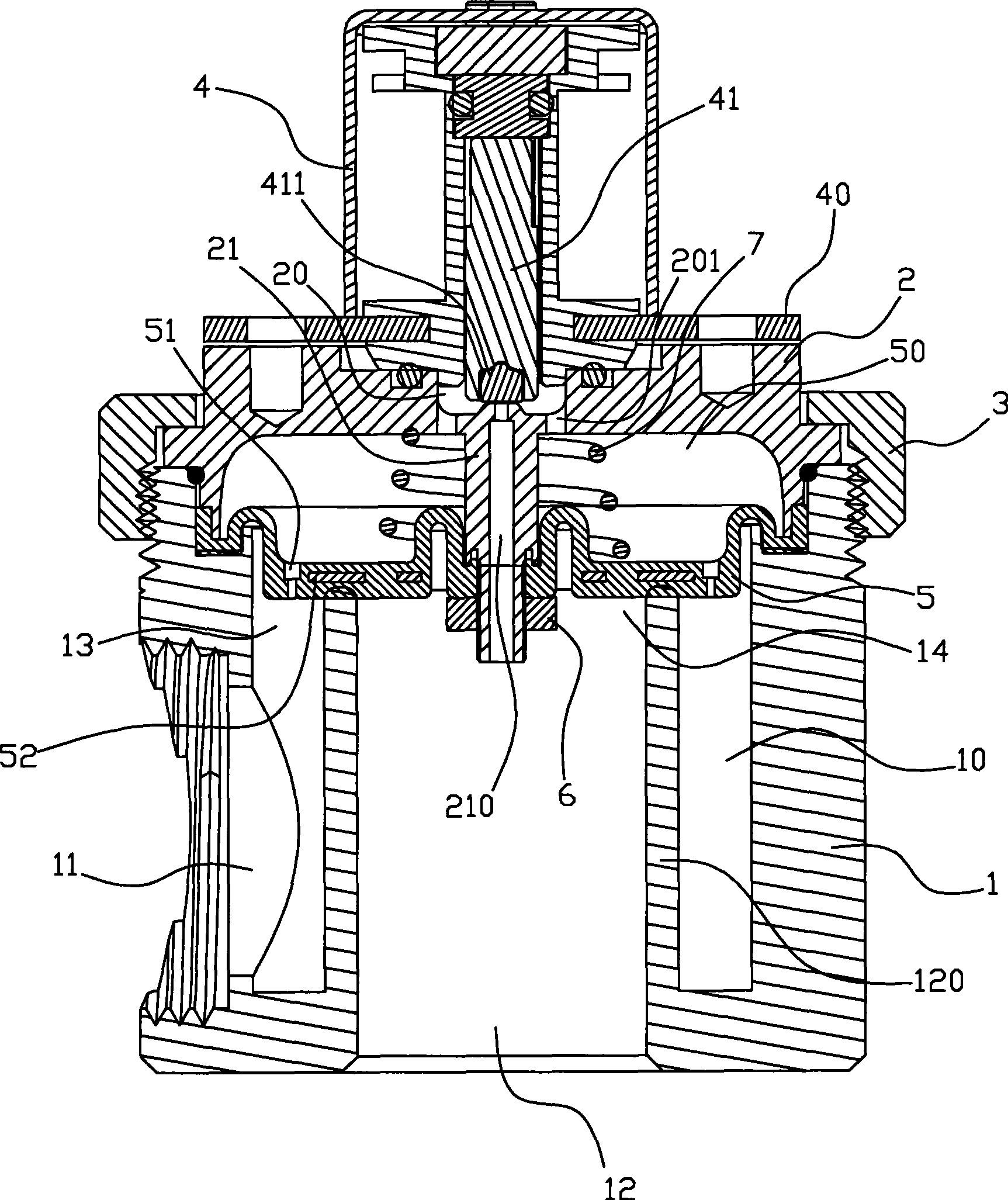

[0027] refer to image 3 and Figure 4 , the structure of this embodiment is basically the same as that of the first embodiment above, the difference is that when the diaphragm valve is in the open or closed state, the shape of the diaphragm 5 of the two is different, and correspondingly, the ring wall 120 and the protrusion 21 of the two are different. The dimensions are also different, and the shapes of the nuts 6 of the two are also different. In addition, the solenoid valve 4 of this embodiment is positioned on the valve cover 2 through a fixing piece 40 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com