Fuel gas cylinder valve

A technology of gas cylinders and valve bodies, which is applied in the direction of valve details, safety valves, balance valves, etc., can solve problems such as insufficient pressure relief speed, high pressure of gas cylinders, and time delay, so as to improve service life and speed up pressure relief , the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

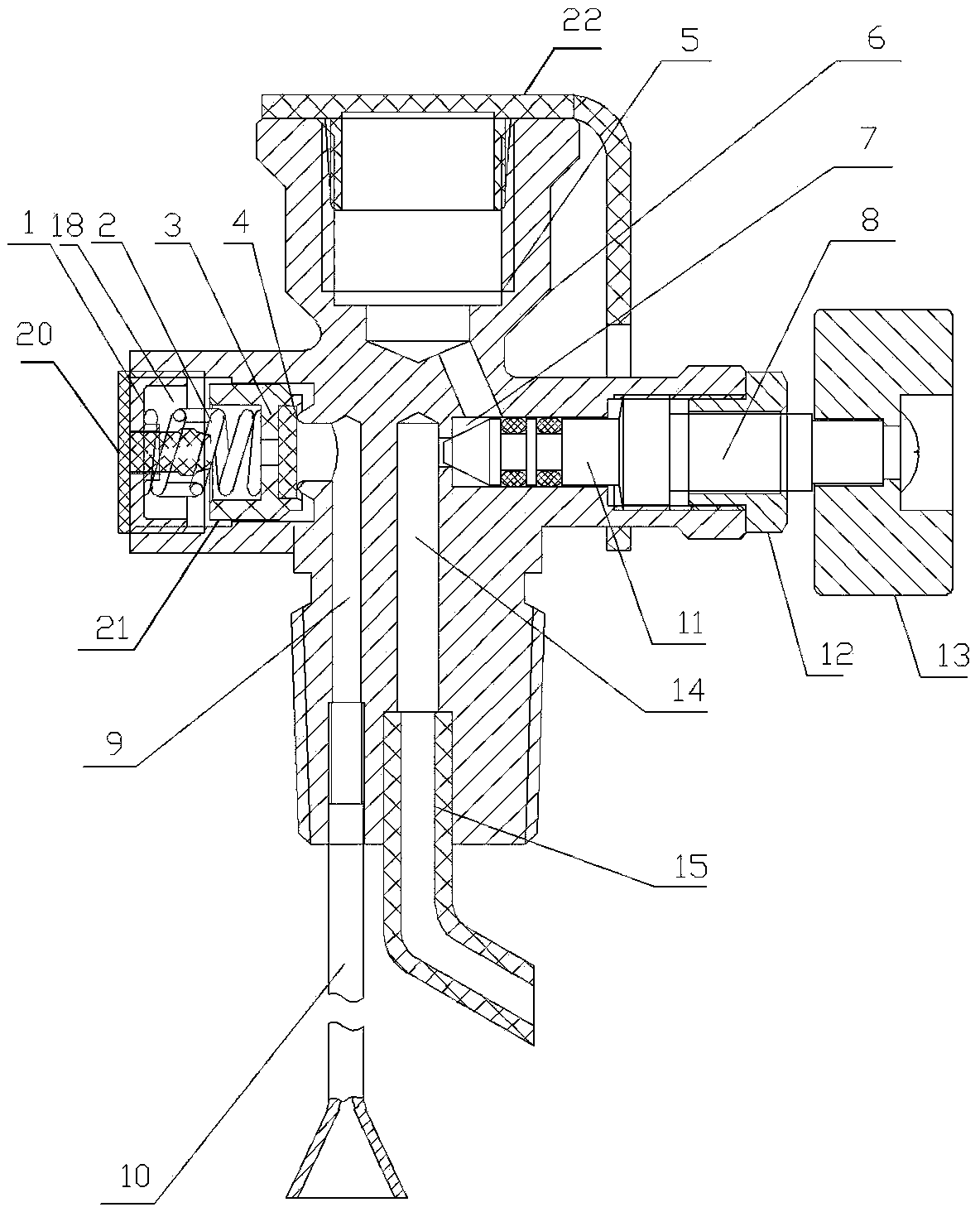

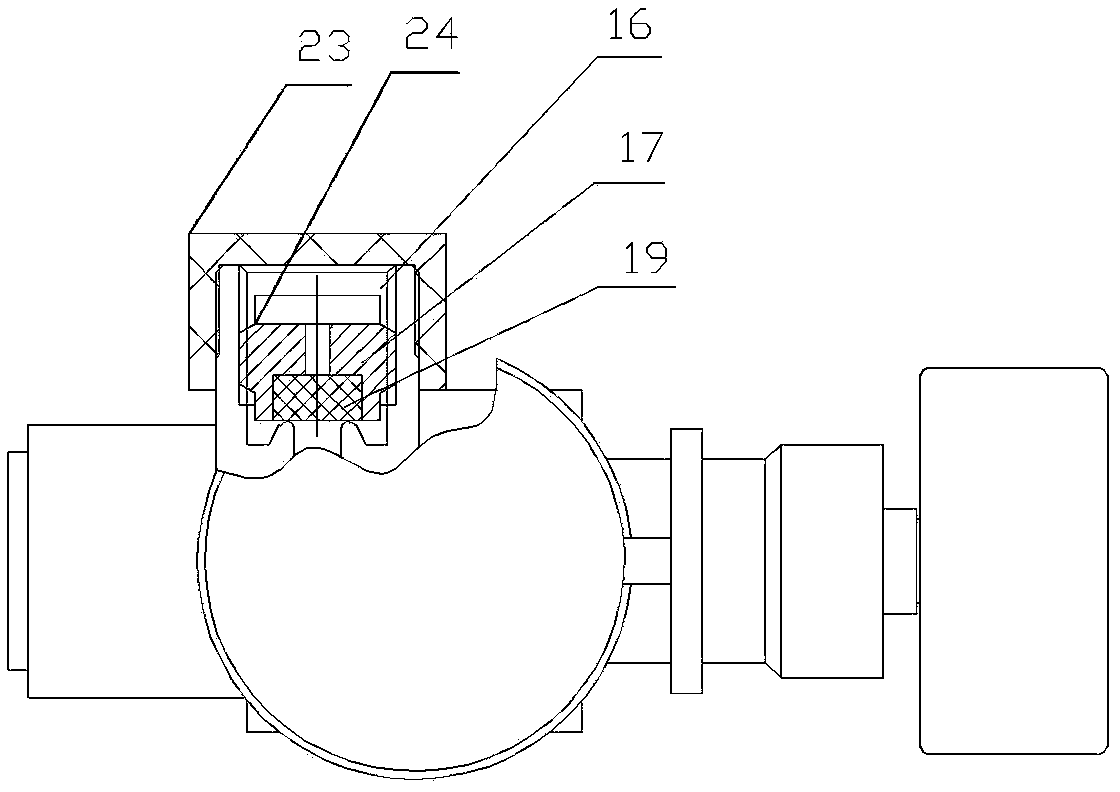

[0022] Such as figure 1 As shown, a gas cylinder valve includes a valve body 6, on which an air connection passage 14 and an air port 5 connected to the outside of the valve body are arranged, the air connection passage 14 communicates with or closes the air port 5 through a switch valve, and the end of the air port is covered A dustproof cover 22 is provided, and one end of the dustproof cover 22 is fixed on the valve body. The lower end of the air connection passage 14 is connected with a trachea 15 protruding from the inside of the valve body, and the end of the trachea is arranged in a curved shape. The bending angle at the end of the trachea is greater than 90°, and the bending part is arranged in an arc. An automatic pressure relief device is installed on the valve body 6, and the automatic pressure relief device includes a pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com