Boiler anti-burning dry safe operation method

A safe operation and anti-drying technology, which is applied to steam boilers, steam boiler accessories, steam boiler components, etc., can solve the problems of steam pollution in the working environment, no longer conforming to safe production, and fuel will not stop synchronously, etc., to achieve The operation steps are simple and easy, the effect of stable operation and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

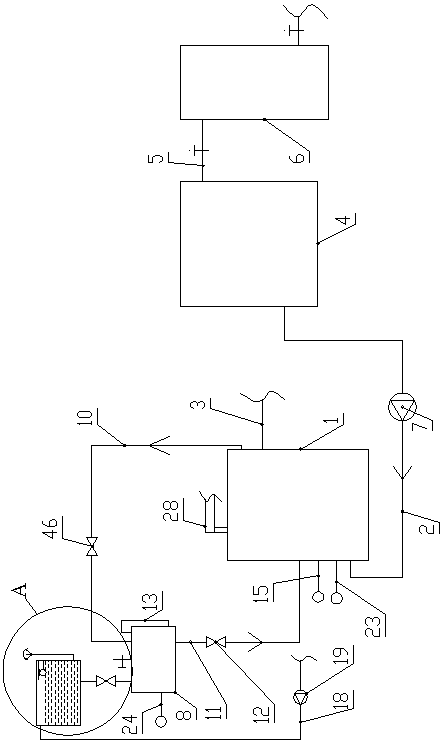

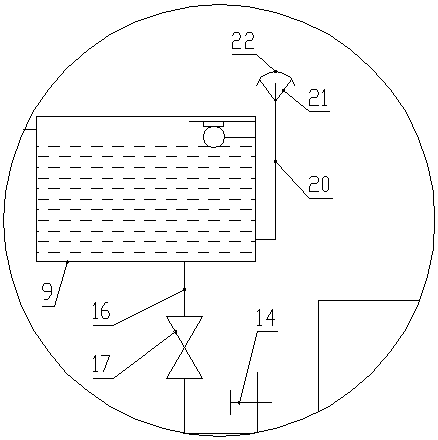

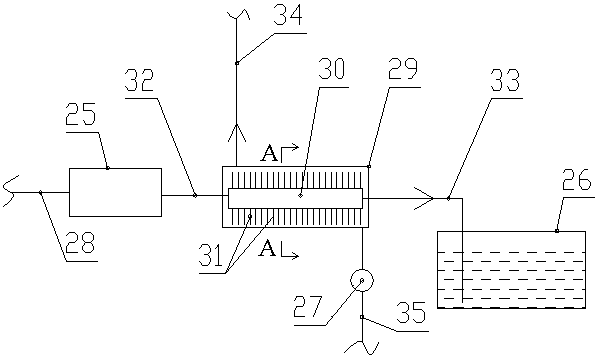

[0040] figure 1 and Figure 7 The direction indicated by the middle arrow is the flow direction of the fluid.

[0041] Such as Figure 1 to Figure 7 As shown, the safe operation method of the boiler for preventing overheating and dryness according to the present invention is implemented by the boiler for preventing overheating and dryness for safe production.

[0042]Boiler anti-drying safety production system includes a boiler, which is equipped with a combustion chamber and a heating chamber 1 (combustion chamber and heating chamber 1 are conventional technology, the part of the combustion chamber is not shown in the figure); the heating chamber 1 is connected to the boiler water inlet pipe 2 and The boiler outlet pipe 3 and the boiler inlet pipe 2 are connected to the softened water tank 4, the top of the softened water tank 4 is connected to the soft water inlet pipe 5, the soft water inlet pipe 5 is connected to the water softener 6, and the water softener 6 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com