A desktop low-melting point metal three-dimensional printer nozzle

A technology of 3D printers and low-melting-point metals, applied in the direction of additive processing, etc., can solve problems such as low precision, redundant printing, and affecting the accuracy of finished products, and achieve the effects of reducing production costs, simplifying production processes, and increasing printing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

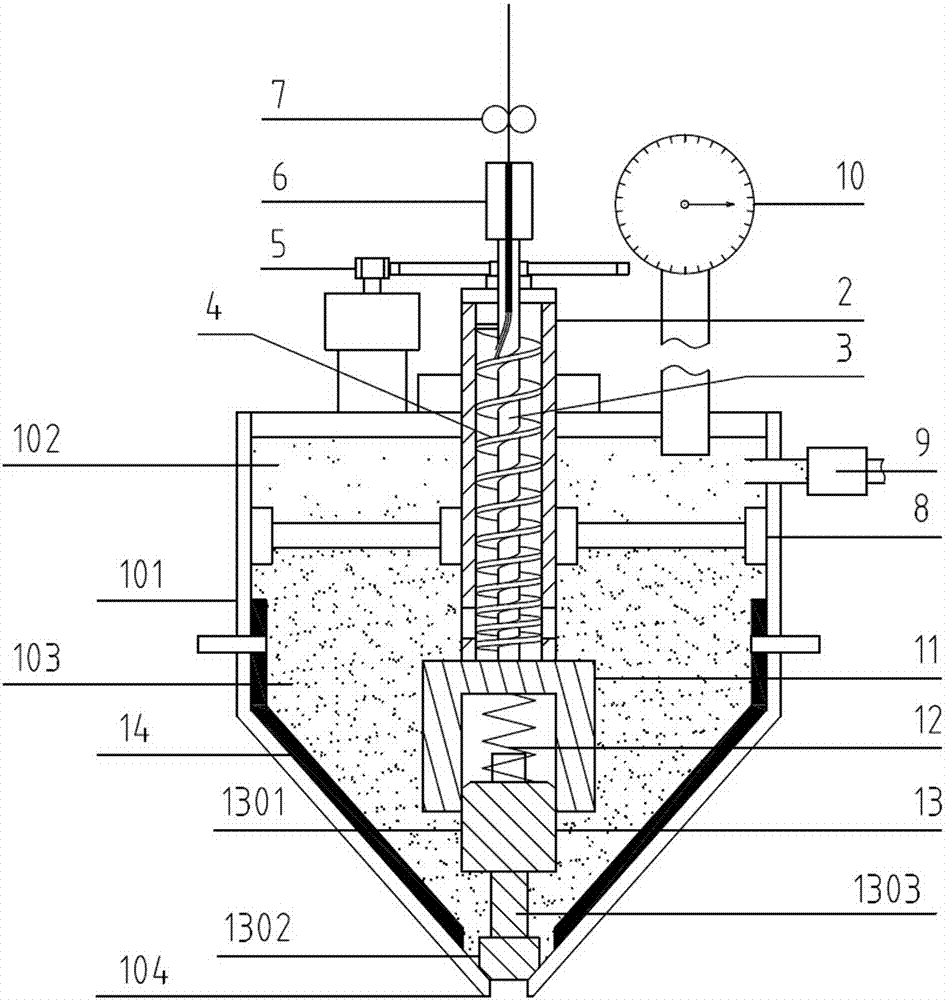

[0023] like figure 1 As shown, a desktop low-melting point metal three-dimensional printer nozzle includes a molten material feeding device, a nozzle body, a molten material discharging device, a piston plate 8, an air pressure controller 9, an air pressure gauge 10 and a heating plate 14;

[0024] The nozzle body is used for storing and ejecting molten material, and includes a nozzle housing 101, an air pressure bin 102, a melting bin 103 and a spout 104. The nozzle housing 101 is provided with an air pressure bin 102 and a melting bin 103, and the air pressure bin 102 Separated from the melting bin 103 by the piston plate 8, the lower end of the nozzle housing 101 is provided with a nozzle 104, the melting bin 103 is connected to the nozzle 104, and the inner wall of the melting bin 103 is provided with a heating sheet 14;

[0025] The air pressure chamber 102 is connected with an air pressure controller 9 for adjusting the air pressure in the air pressure chamber 102 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com