Glue dispenser for glue filling of air cylinders

A dispensing machine and cylinder technology, which is applied to the surface coating liquid device, coating, etc., can solve the problems of slow pressure relief speed, large inner diameter of the material barrel, and slow pushing speed, so as to achieve faster pressure relief speed, The effect of stable pressure and adjustable pushing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing:

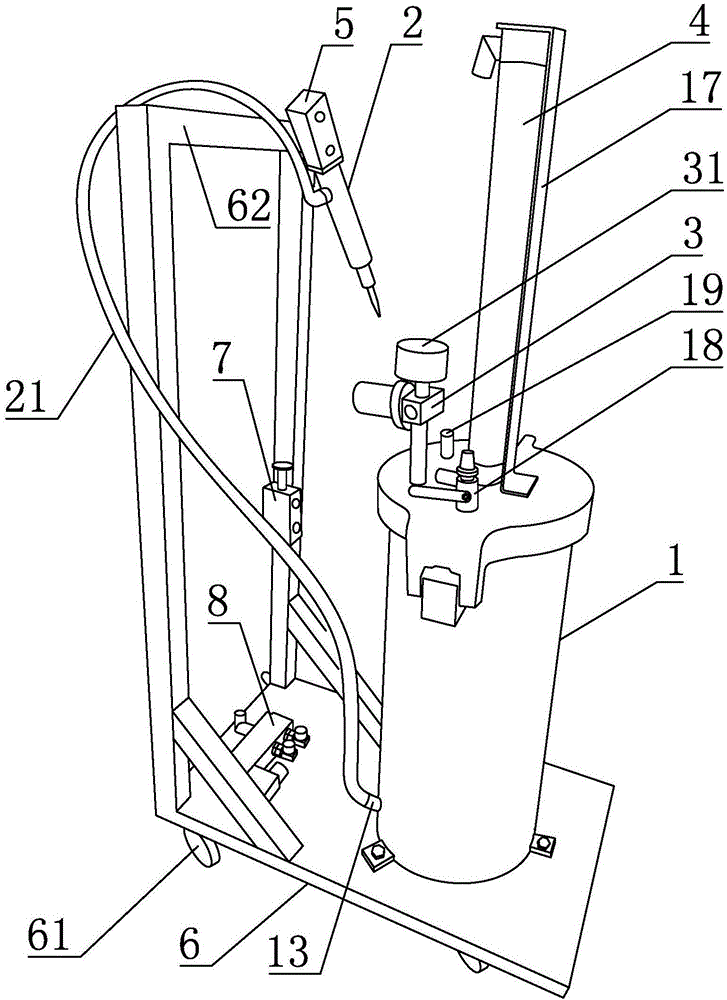

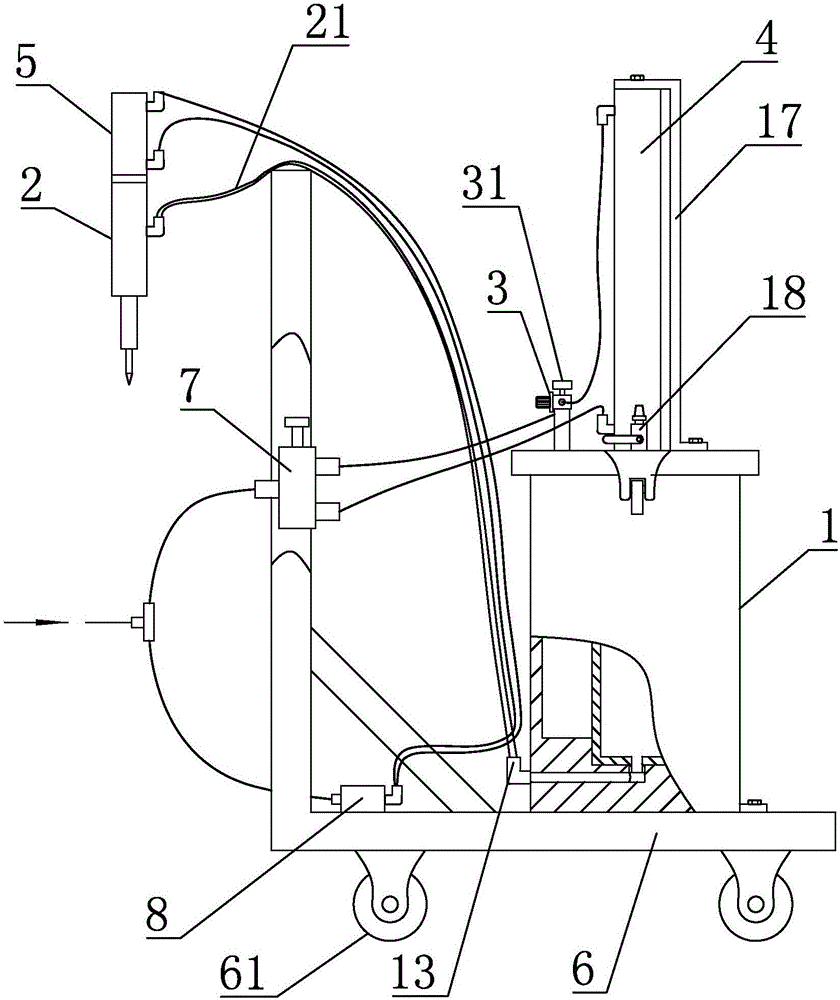

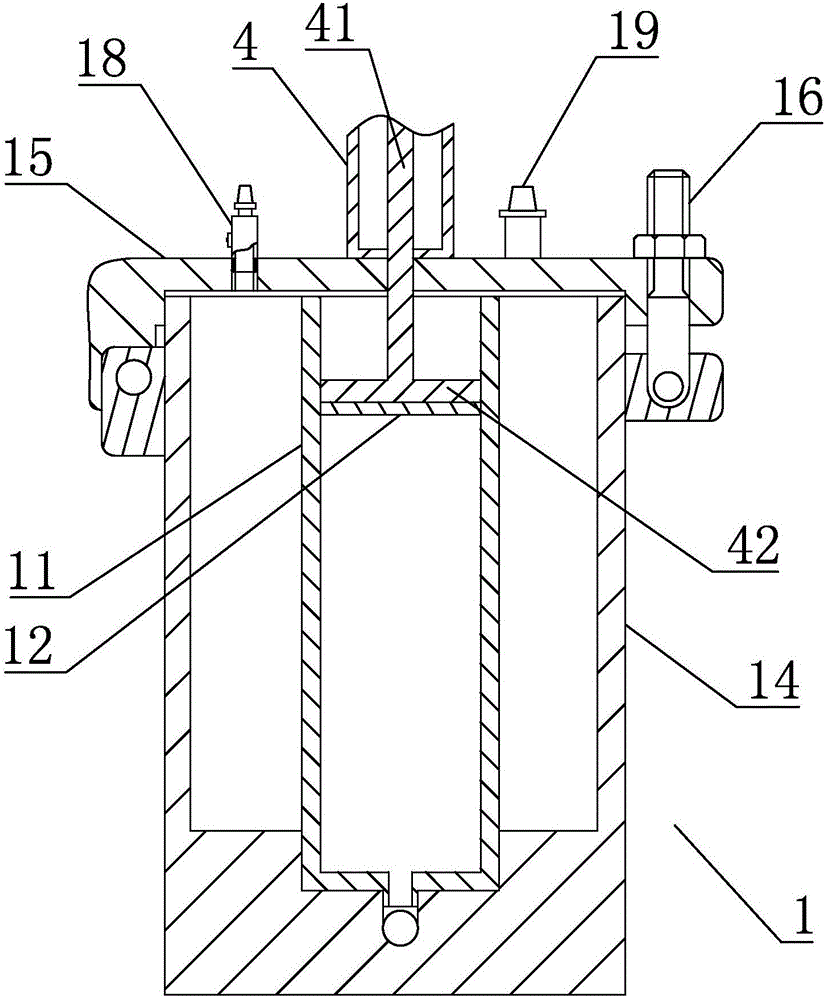

[0019] refer to figure 1 , a dispensing machine for cylinder glue replenishment of the present invention, comprising an air source supplied by an air compressor, a material barrel 1 that can accommodate glue, and a dispensing gun 2. The material barrel 1 is a cylindrical long barrel, and its Vertically installed on the movable trolley 6, the trolley 6 is a rectangular flat plate, and four movable wheels 61 are installed on its bottom, wherein one of the movable wheels 61 is provided with a brake device, and the brake device is stepped on when parking Just can position trolley 6, prevent its activity or slide away. Cart 6 one side is also provided with handrail 62, and handrail 62 is to comprise two columns, and the top of two columns is connected by a crossbeam, and the height of crossbeam is set to be flush with the waist of ordinary people, and hand-holding crossbeam can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com