Rapid suppressing device of high-speed hydraulic stamping press

A technology of high-speed stamping and hydraulic presses, which is applied in the field of pressing devices of hydraulic presses, can solve the problems of high-speed stamping hydraulic presses such as the decrease in working efficiency, high operating frequency, sliding block running speed, and large volume of the control chamber, so as to improve energy efficiency and working efficiency. The effect of short, small control volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

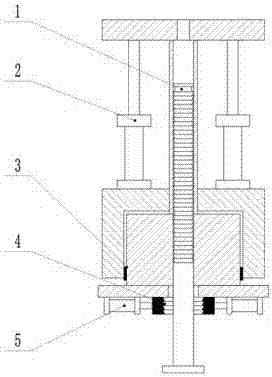

[0022] see figure 1 , the present invention mainly includes: a dowel rod 1, a plunger return cylinder 2, a short-stroke plunger cylinder 3, a force transmission claw 4, and a driver 5.

[0023] see figure 1 A section of the dowel 1 of the present invention has fine teeth in the shape of elephant trunks, the length of the dowel 1 is adapted to the stroke of the hydraulic press slider, and the lower end of the dowel 1 has a connecting flange .

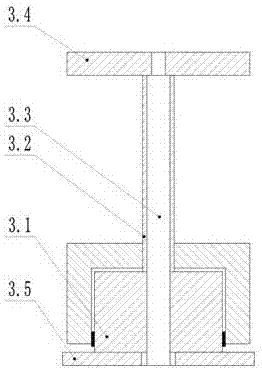

[0024] see figure 2 , the short-stroke plunger cylinder 3 of the present invention mainly includes a plunger 3.1, a sleeve 3.2, a through hole 3.3, a return connecting plate 3.4, and a connecting plate 3.5. There is a through hole in the middle of the plunger 3.1, and there is a A section of sleeve 3.2, the plunger 3.1 and the sleeve 3.2 are an integral component, the inner hole of the sleeve 3.2 is coaxial with the middle t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com