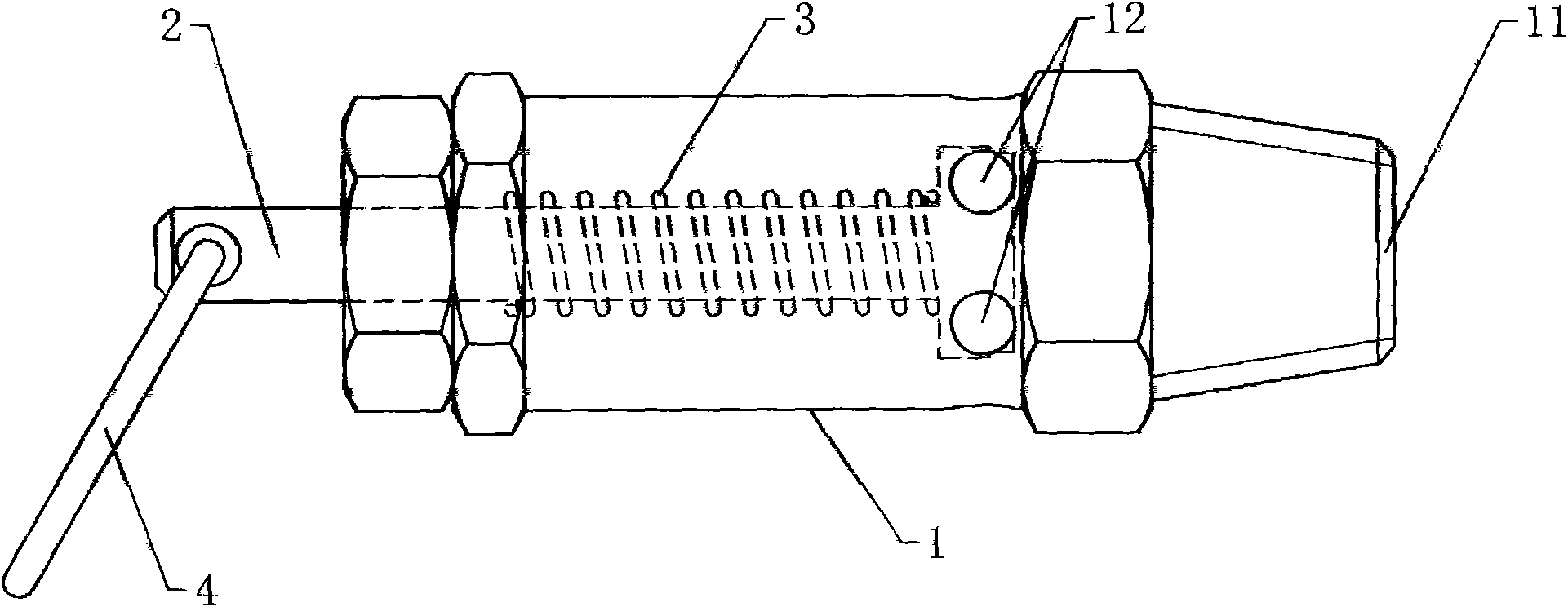

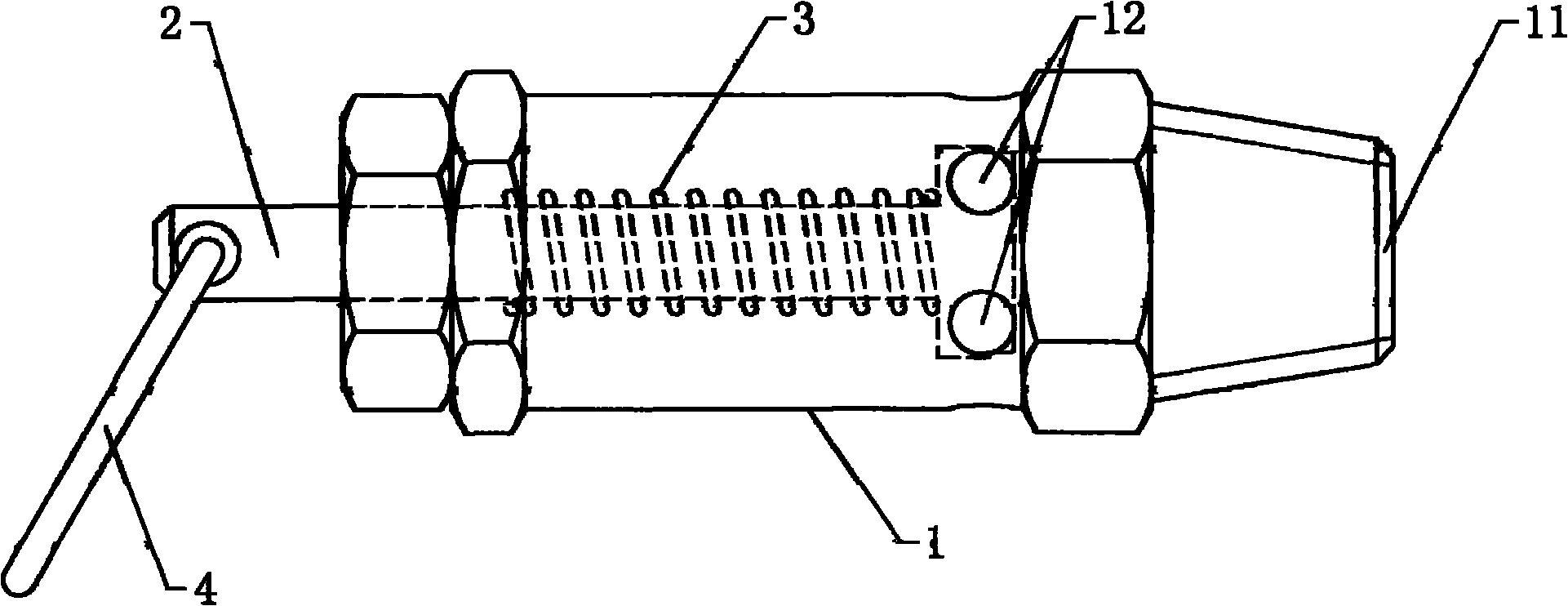

Pressure relief and noise reduction safety valve

A safety valve and noise reduction technology, which is applied in the field of safety valves, can solve problems affecting the comfort of driving vehicles, loud noise, etc., and achieve the effects of reducing amplitude and frequency, improving comfort, and reducing noise duration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] A pressure relief and noise reduction safety valve, as shown in the accompanying drawings, it includes a valve body 1 and a valve core 2, the valve body 1 is provided with an air inlet 11 and an exhaust port 12, and the exhaust port 12 is Several exhaust holes, the valve core 2 is slidingly installed in the valve body 1, and there is a valve between the valve core 2 and the valve body 1 that compresses the valve core 2 and the air inlet 11 Elastic pressing part 3 with sealing fit. The elastic pressing member 3 is a compression spring, and the compression spring is squeezed between the valve body 1 and the valve core 2, and the valve core 2 and the air inlet 11 are hermetically fitted by the spring pressure of the spring itself. Preferably, the exhaust holes are six radial exhaust holes uniformly distributed on the outer circumference of the valve body 1 . The exhaust hole is located at the sealing fit between the valve core 2 and the air inlet 11 . The outer end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com