Planar test device for rock slope destruction and test method thereof

A technology for rock slopes and test devices, which is applied in the direction of measuring devices, machine/structural component testing, instruments, etc., can solve the problems of limited number of tests, low utilization rate of test devices, and influence on the test process, so as to improve the test process , The structure is simple and novel, and the effect of improving the test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

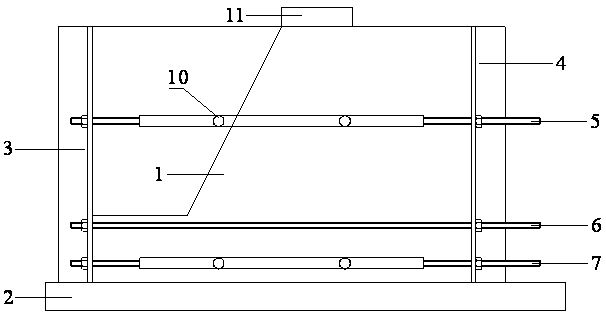

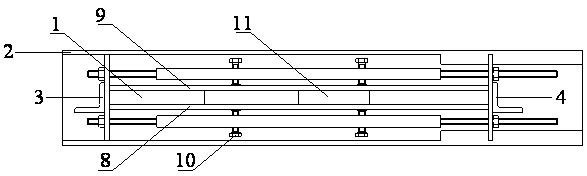

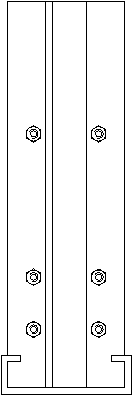

Method used

Image

Examples

Embodiment 1

[0036] Example 1: Research on the Influence of Main Control Joint Dip Angle on Rock Slope Failure under Slope Top Load

[0037] (1) On a rocky slope of a highway, field geological surveys show that there is a main controlling joint in the slope body. The influence of the main controlling joint dip angle on the rock slope failure under the action of the slope top load is analyzed, and the joint dip angle changes from 0 degrees to 90 degrees degrees, and the inclination increment is 15 degrees, that is, 0 degrees, 15 degrees, 30 degrees, 45 degrees, 60 degrees, 75 degrees and 90 degrees respectively, a total of 7 schemes, and three identical models are poured for each scheme. According to the proportional relationship between the slope model and the prototype, the slope mold is made, and the slope model materials are prepared according to the weight ratio of each material, gypsum: barite: fine sand: water = 1:1:2:1. The slope model is poured, and mica sheets are used to simulate...

Embodiment 2

[0044] Example 2: Research on the influence of main control joint dip angle on rock slope failure under the action of gravity increase

[0045](1) On a rocky slope of a highway, field geological survey shows that there is a main controlling joint in the slope body. The influence of the dip angle of the main controlling joint on the failure of the rock slope under the action of increasing gravity is analyzed, and the dip angle of the joint varies from 0° to 90° , the inclination increment is 15 degrees, that is, 0 degrees, 15 degrees, 30 degrees, 45 degrees, 60 degrees, 75 degrees and 90 degrees are taken respectively, and there are 7 schemes in total, and three identical models are poured for each scheme. According to the proportional relationship between the slope model and the prototype, the slope mold is made, and the slope model materials are prepared according to the weight ratio of each material, gypsum: barite: fine sand: water = 1:1:2:1. The slope model is poured, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com