Method for mounting a front axle/cradle assembly to a body part of a motor vehicle

A technology for the installation of main parts and components, which is applied in the direction of motor vehicles, vehicle parts, upper structure sub-assemblies, etc., and can solve complex and expensive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

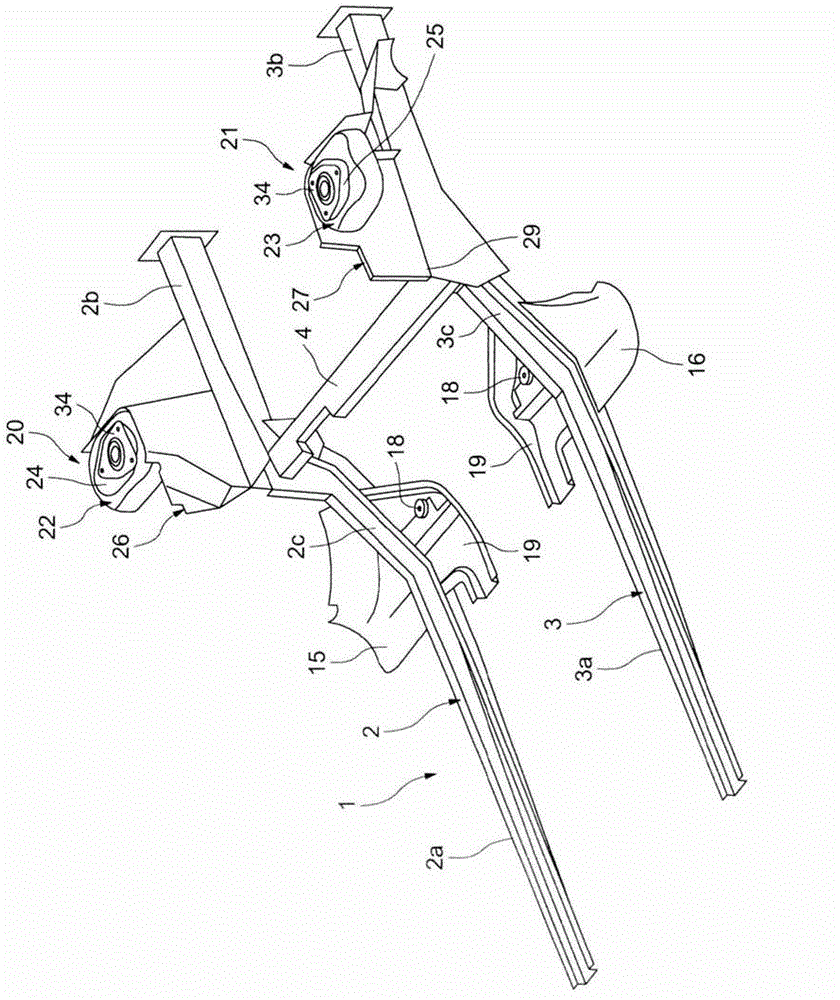

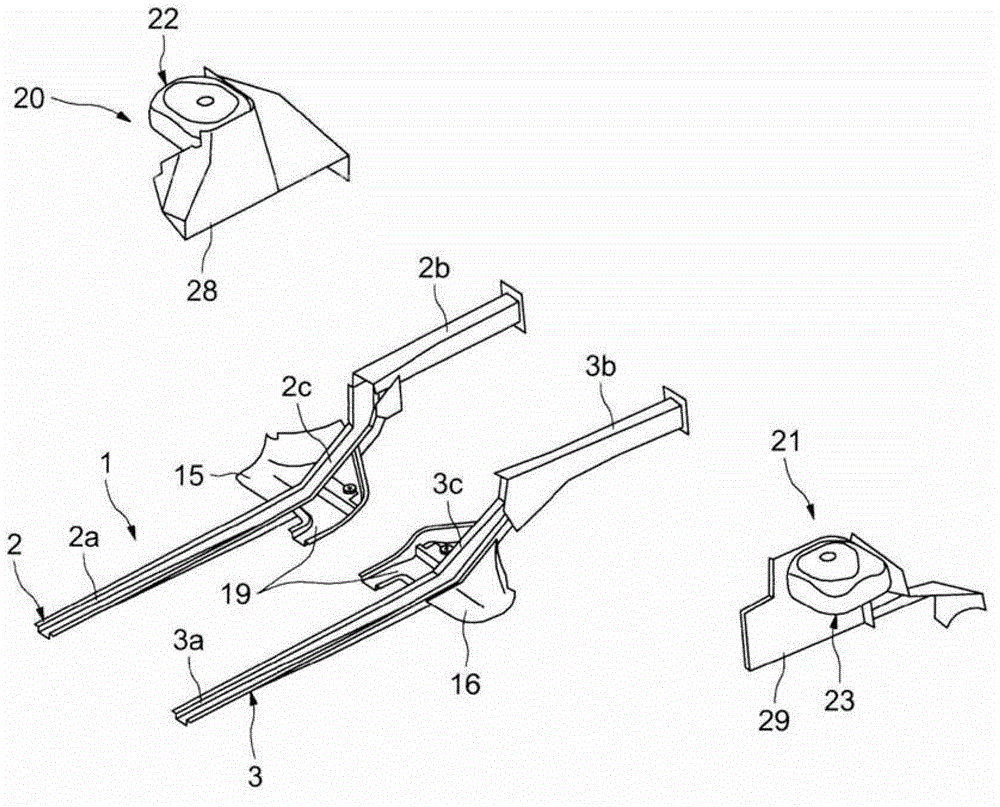

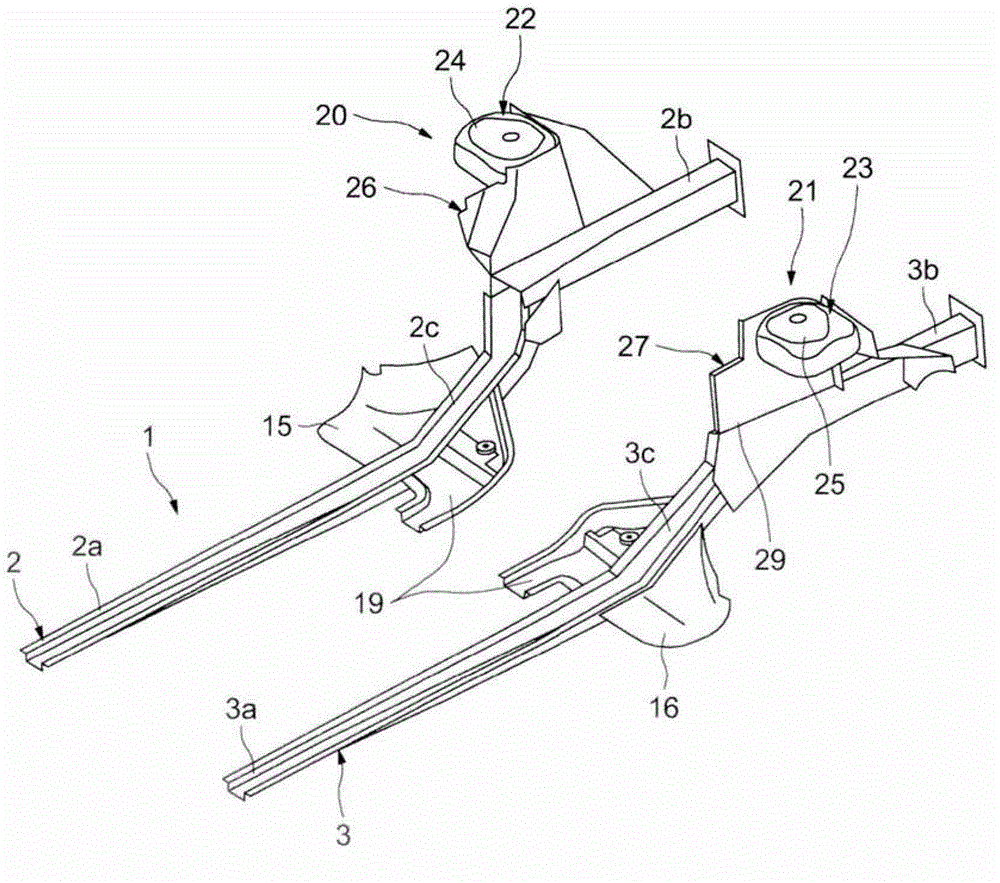

[0035] Figures 1 to 8 A part of a car subframe is shown, comprising a support structure 1 comprising two struts 2, 3 placed symmetrically with respect to the longitudinal center plane of the vehicle on the right and left side of the vehicle.

[0036] Each of the struts 2, 3 comprises a left central beam 2a and a right central beam 3a and a left front beam 2b and a right front beam 3b on the corresponding side of the vehicle, the front beams are towards the front of the vehicle and at a higher level than the central beams 2a, 3a , and is connected to the central beams 2a, 3a on the left and right by inclined beams 2c, 3c.

[0037] Respective rear ends of the left front beam 2 b and the right front beam 3 b are connected by a cross beam 4 .

[0038] The struts 2, 3 of the support structure each extend from a partition 5 to which they are permanently fixed, in particular by welding.

[0039] The assembly consisting of the struts 2, 3 of the support structure 1, the beam 4 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com