Hydraulic lifting device of carrier

A hoisting device and hydraulic technology, which is applied in the direction of tilt-bearing vehicles and other directions, can solve the problems of affecting the appearance and complicated operation, and achieve the effects of convenient and labor-saving operation, high lifting efficiency and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

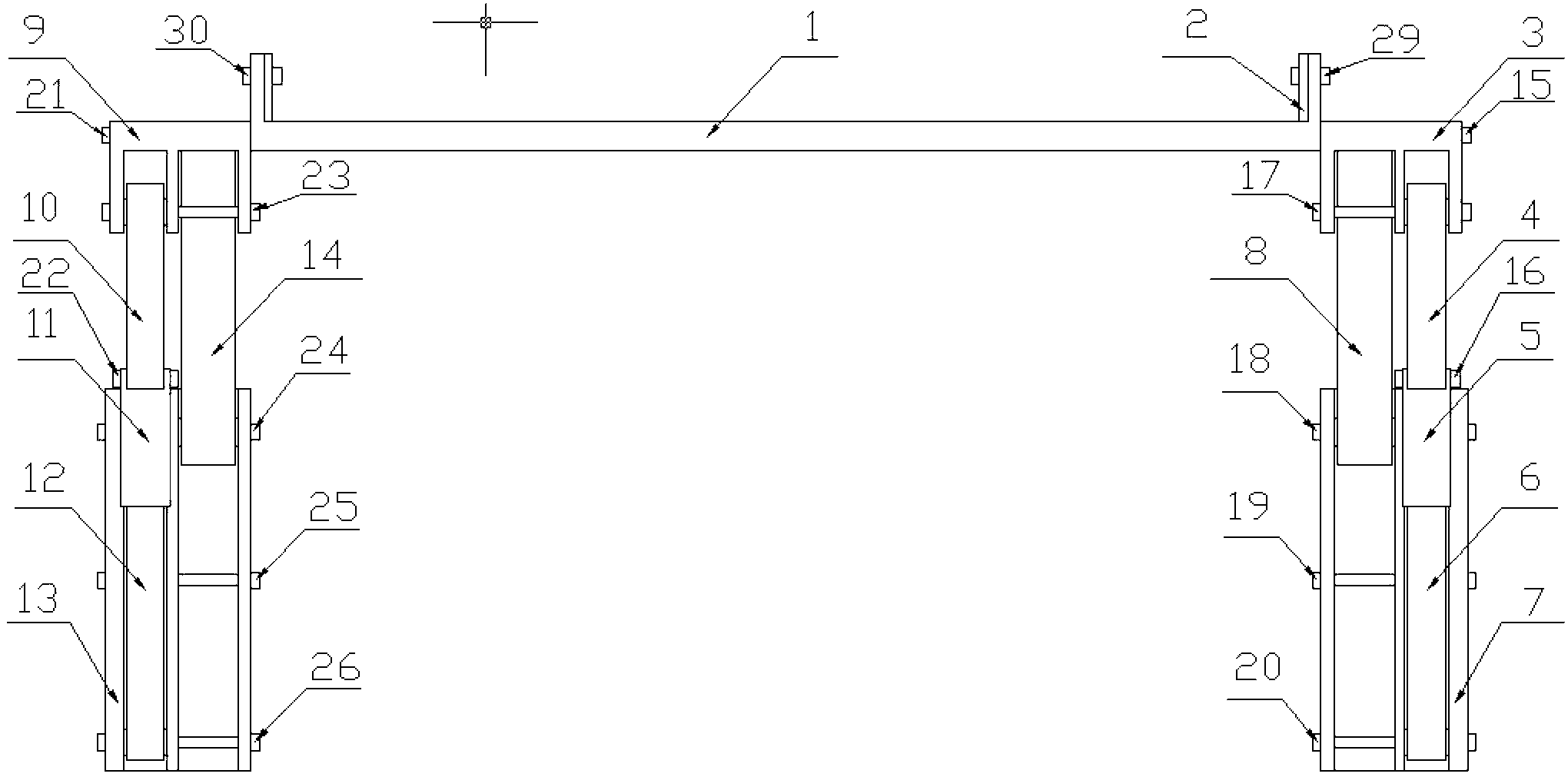

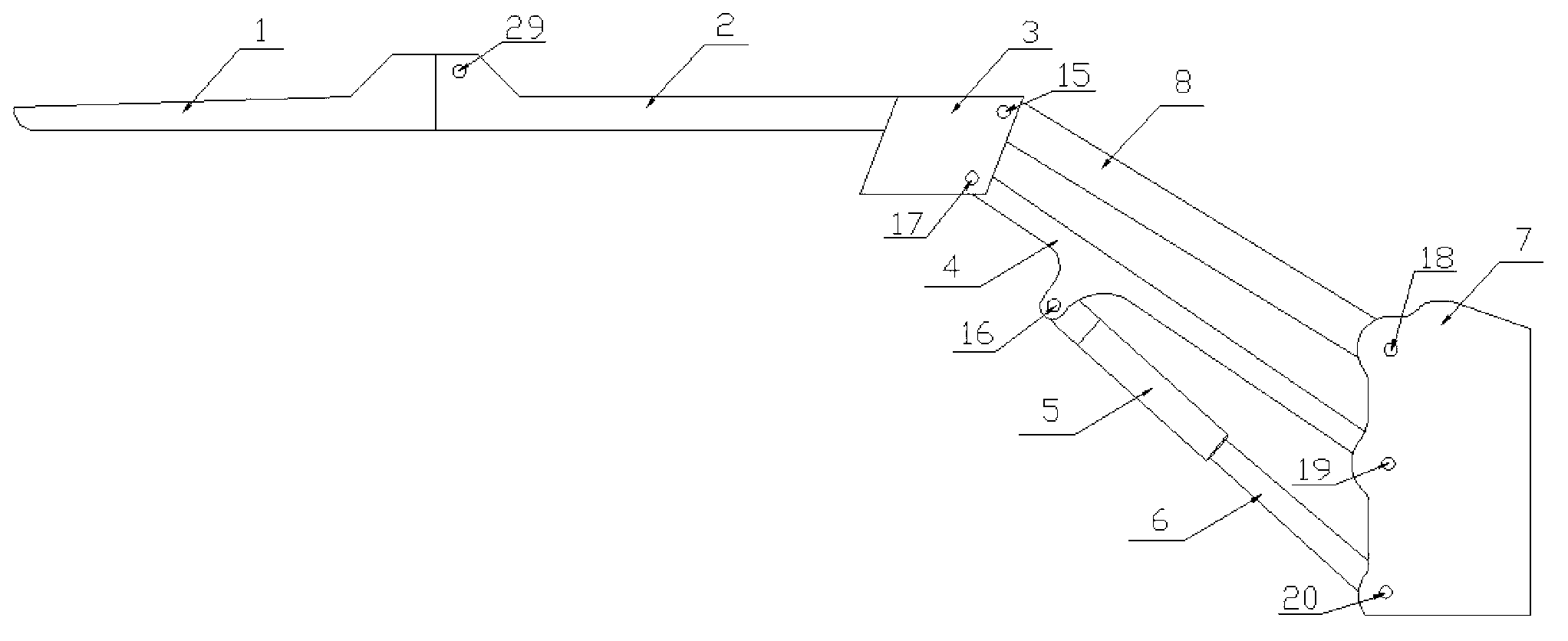

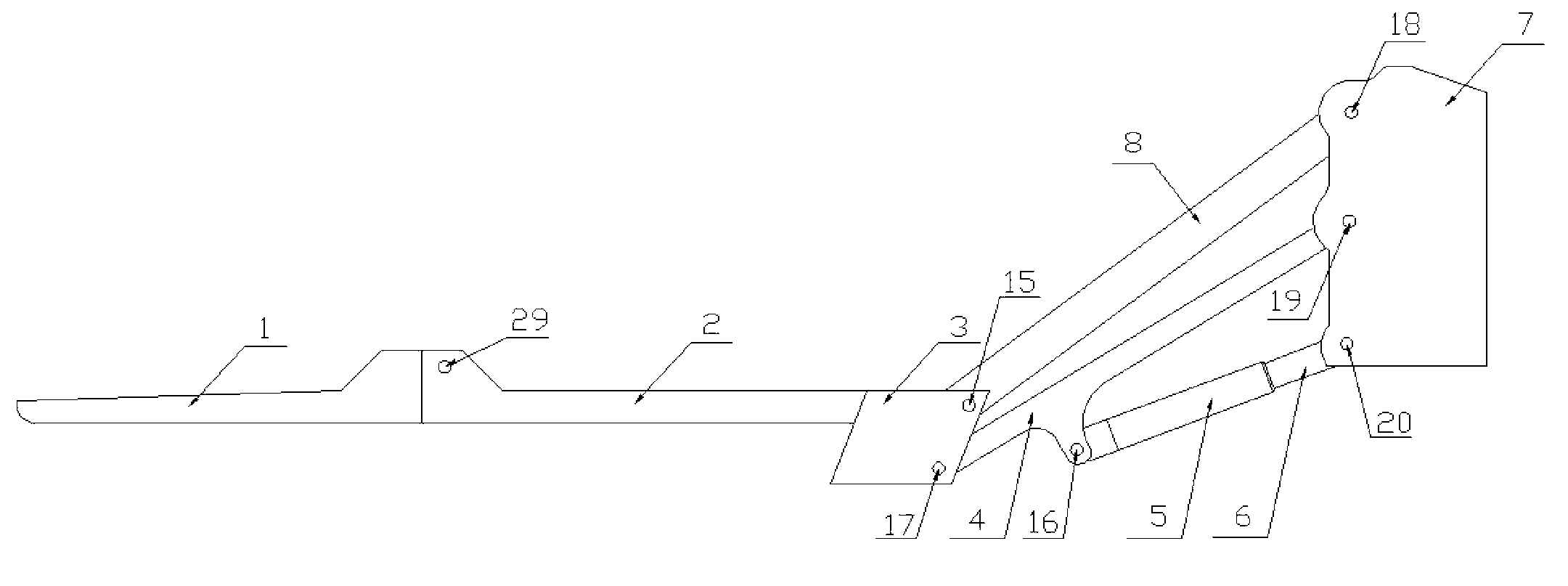

[0024] Below according to accompanying drawing and embodiment the present invention will be described in further detail:

[0025] refer to figure 1 , figure 2 , image 3 , Figure 4 As shown, the vehicle hydraulic lifting device includes a foldable primary wedge-shaped plate 1 and a secondary plate 2, and the primary wedge-shaped plate 1 and the secondary plate 2 are connected by bolts 29 and 30. The second-level flat plate is composed of the flat plate and the front hinge support 3 and the front hinge support 9 on both sides away from the bottom of the wedge-shaped flat end of the first level; There are upper pin holes, lower pin holes and connecting bolts, and the secondary plate 2 is fixedly connected with the front hinge support 3 and the front hinge support 9.

[0026] The horizontal lifting mechanism includes the two sides of the foldable carrying platform, each consisting of upper lifting arms 8 and upper lifting arms 14 on both sides, lower lifting arms 4 on both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com