Deformable assembly

A frame and rigid frame technology, applied in aircraft parts, ground installations, transportation and packaging, etc., can solve problems such as hidden safety hazards, poor flexibility and sealing, lack of real-time detection and alarm devices for passengers, etc. sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

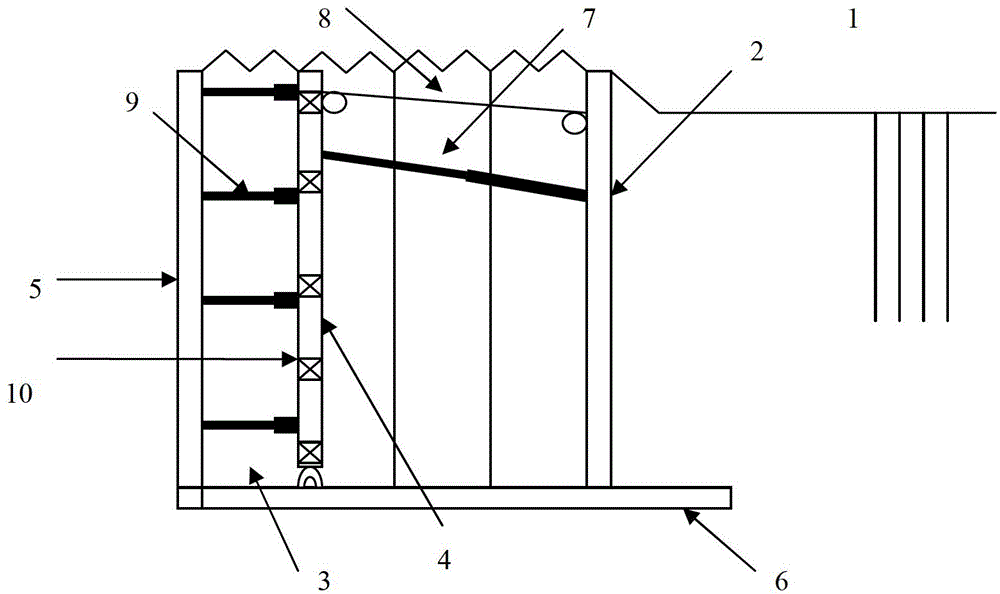

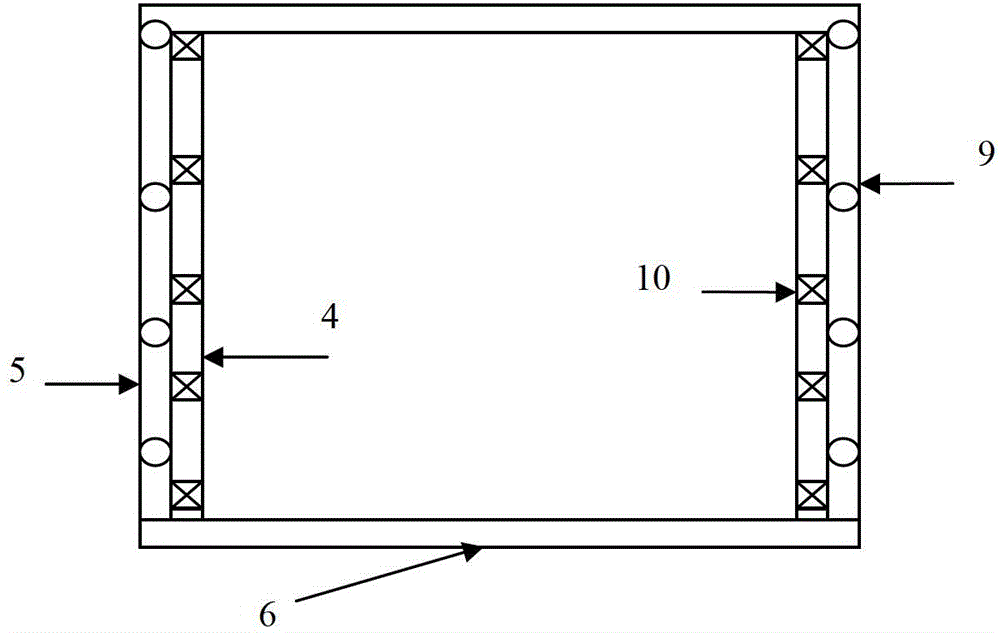

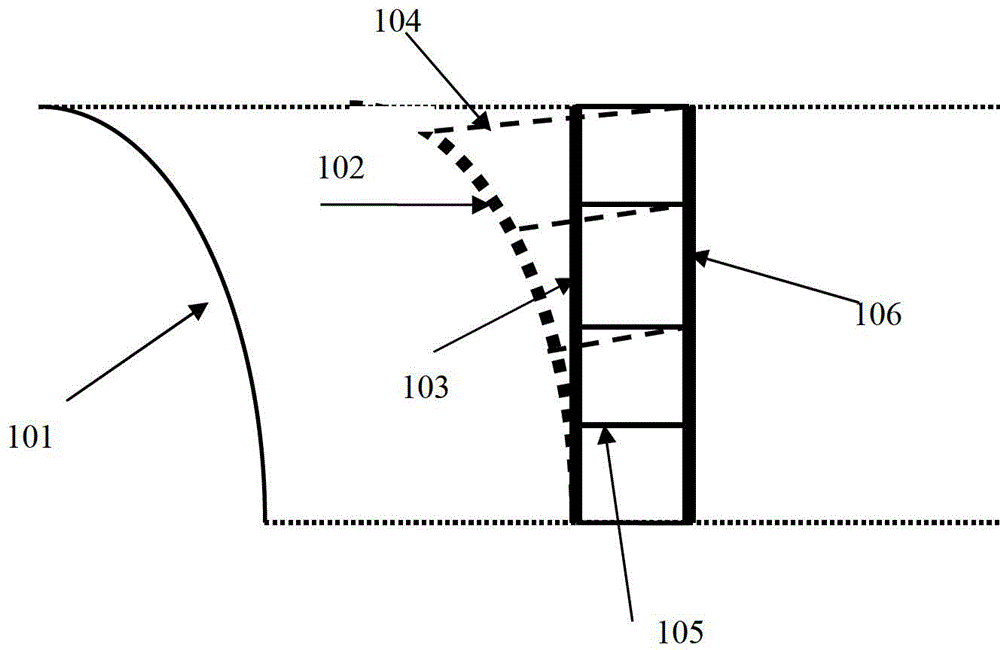

[0015] Refer to attached figure 1 , which shows a canopy device 1 comprising a docking frame according to the present invention, the bellows device 1 includes a door-shaped frame 2 and a docking frame 3, and the docking frame 3 is directly used to realize the docking of the bellows device 1 with the aircraft fuselage shell . The docking frame 3 includes a rigid frame 4 and a flexible frame 5 that will be in direct contact with the fuselage shell. The flexible frame 5 is made of flexible material, but the material has poor ductility, such as plastic. The flexible frame may further include cushioning materials, air cushions or elastically deformable tubes, etc. around the flexible frame. The door frame 2 is fixedly connected to the floor layer 6 . The floor layer is a non-retractable fixed floor layer that cannot change shape. The hard frame 4 is then pivotally hinged to the floor layer 6 of the bellows device 1, and the hard frame 4 may also include a snap lock device that c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com