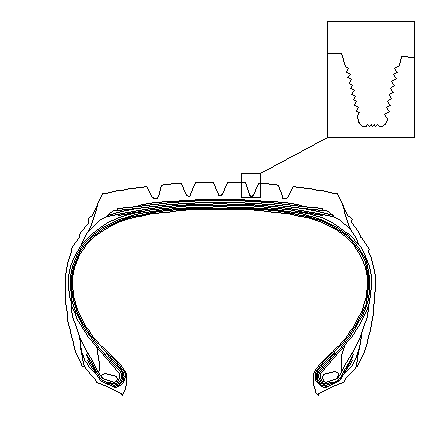

Bionic non-skid tire pattern groove

A technology of anti-skid tires and grooves, which is applied in the direction of tire tread/tread pattern, tire parts, transportation and packaging, etc., and can solve the problems of increasing the cross-sectional area of tread grooves and increasing tire noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

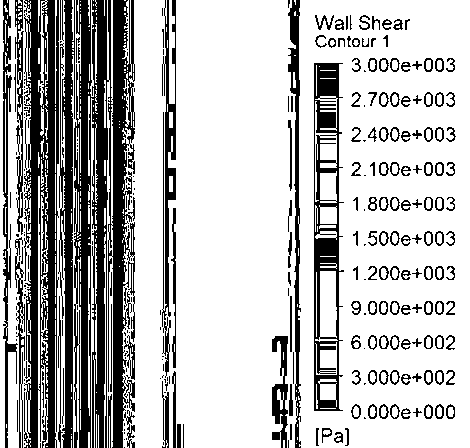

[0010] Depend on figure 2 It can be seen that the wall shear force at the bottom of the tire tread groove with the non-smooth surface of the V-shaped groove is smaller than that without arrangement, and it is particularly prominent at the bottom of the V-shaped groove. This structure can reduce the flow of rainwater from the tread groove. The resistance encountered when discharging from the tank.

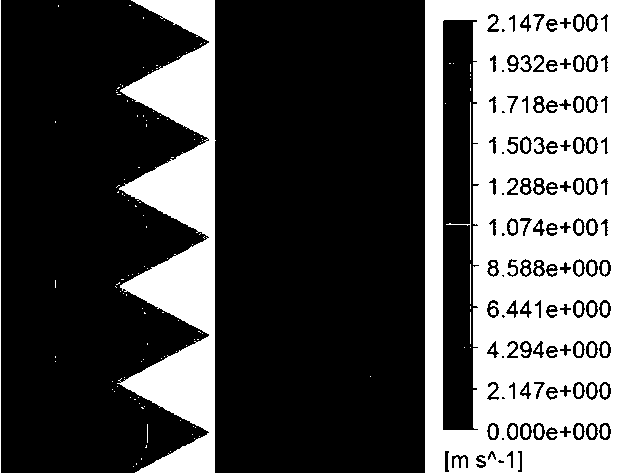

[0011] Depend on image 3 It can be seen that the velocity gradient in the near-wall area of the non-smooth surface of the V-shaped groove is small, and the thickness of the boundary layer is large, thereby reducing the energy loss caused by eddy motion in the boundary layer, achieving the effect of reducing drag, and improving The drainage volume of the pattern groove increases the hydroplaning speed of the tire.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com