Magnetron sputtering device

A magnetron sputtering device and magnet technology, applied in sputtering plating, ion implantation plating, coating, etc., can solve the problems of complexity, heavy weight, and 10 large magnet units, and achieve the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach )

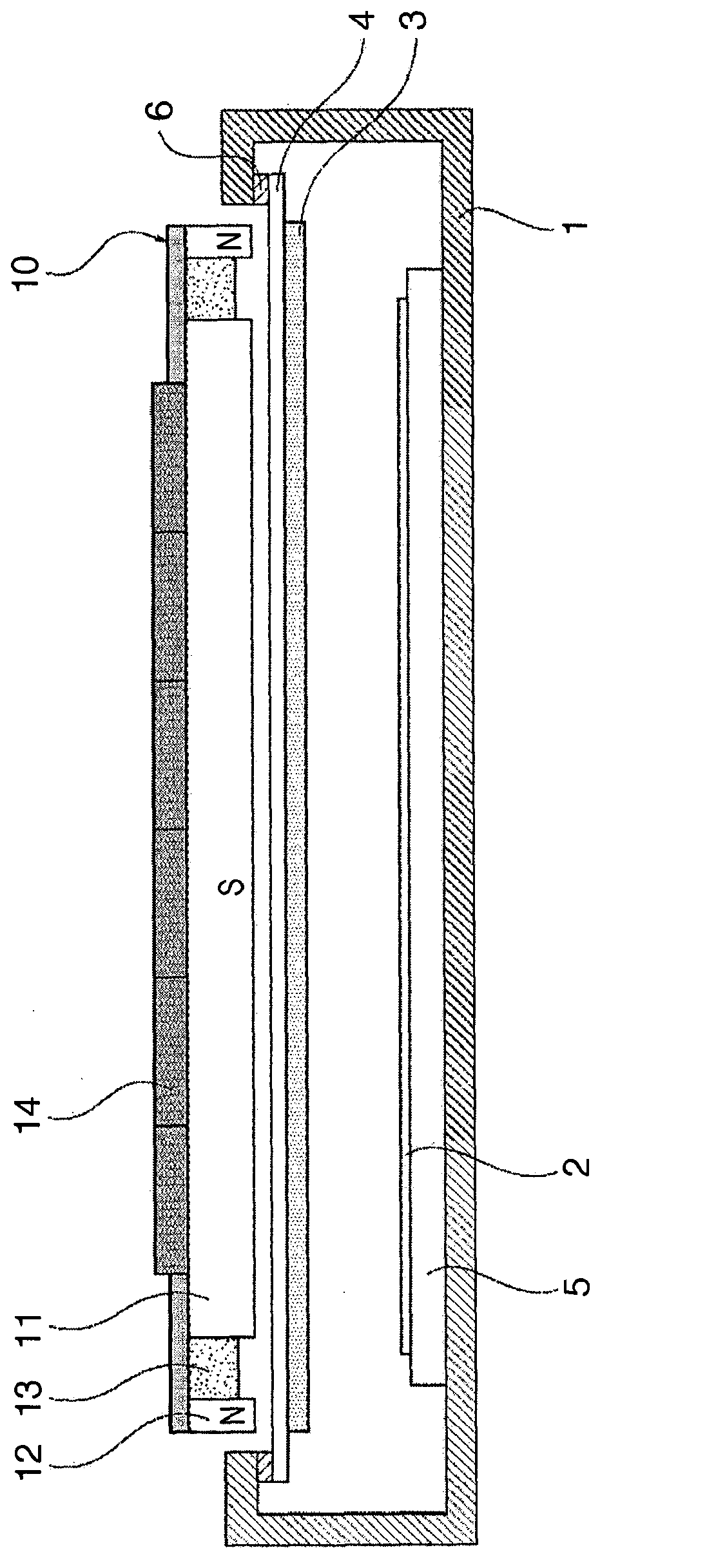

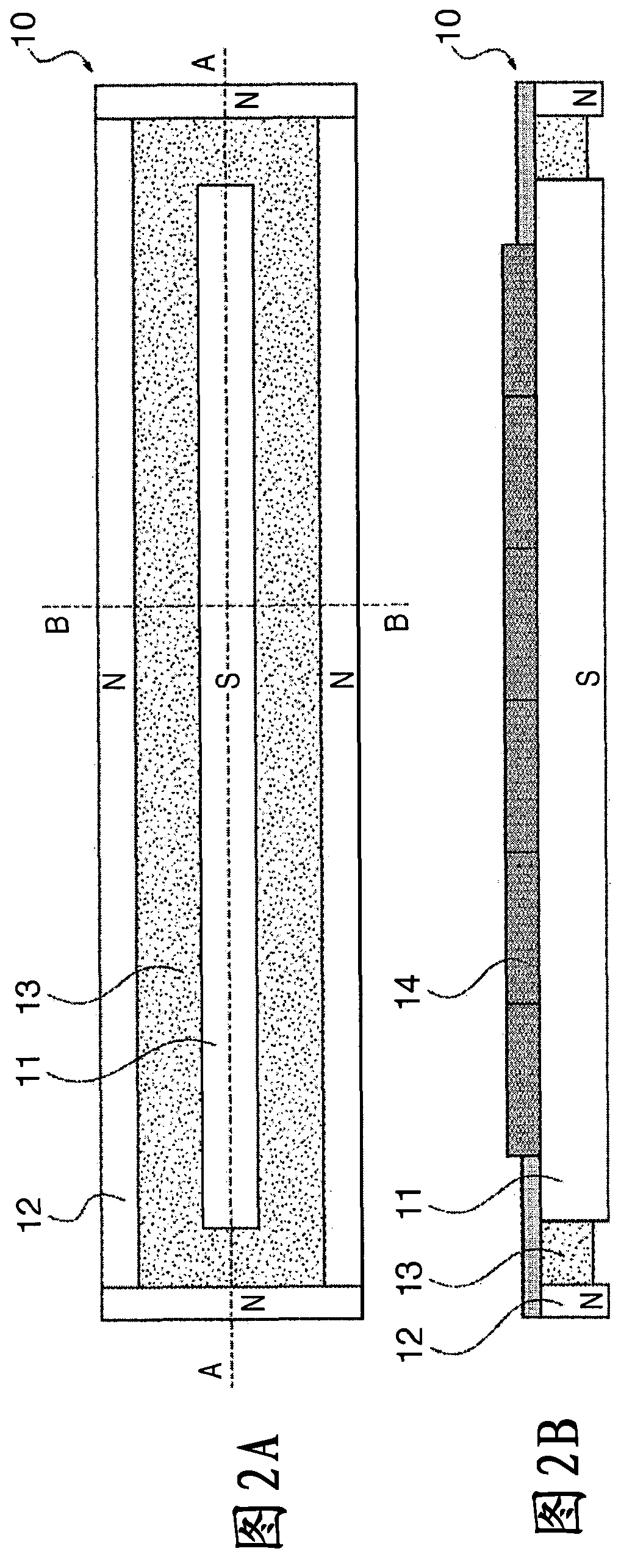

[0043] Next, a magnetron sputtering apparatus according to a first embodiment of the present invention will be described with reference to the drawings. figure 1 The schematic structure of the magnetron sputtering apparatus concerning this embodiment is shown in . A substrate 2 is placed on a substrate rack 5 in the chamber 1 . The chamber 1 is evacuated to a vacuum by an exhaust pump not shown, and a process gas such as Ar gas is supplied through a gas pipe not shown to form a predetermined pressure.

[0044] The target 3 is disposed above and facing the substrate 2 . The cathode 4 enables the target 3 to be mounted on the mounting surface, and the cathode 4 is installed in the cavity 1 through the insulator 6 .

[0045] In this embodiment, an example is shown in which the rear surface side of the cathode 4 where the target 3 can be mounted is exposed to the air. The cathode 4 is connected to an unillustrated DC power supply. On the back side of the cathode 4, a magnet u...

no. 2 Embodiment approach )

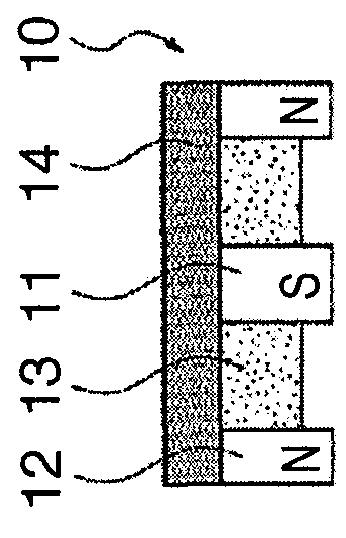

[0066] Next, a second embodiment of the present invention will be described. exist Figure 7A The inner magnet 11 and the outer magnet 12 of the magnet unit 10 shown have magnets 15 made of ferromagnets such as iron and SUS430 respectively connected to the magnetic poles on the opposite side to the target 3 by adhesive or the like. A magnet 15 connected to the inner magnet 11 and the outer magnet 12 is connected into the magnetic circuit via the yoke 14 .

[0067] The yoke 14 is not fixed by an adhesive or the like, but is attached only by the attraction force (magnetic force) of the magnets (inner magnet 11 , outer magnet 12 ), and thus can be removed. There is a non-magnetic body 13 between the inner magnet 11 and the outer magnet 12, and the magnet 15 and the non-magnetic body 13 are fixed by an adhesive, bolts, or the like.

[0068] The structure of the magnet unit 10 without the yoke 14 is in Figure 7B shown in . Since the magnet 15 and the non-magnet 13 are fixed, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com