A kind of shear magneto-rheological buffer compensator

A magneto-rheological and compensator technology, applied in the direction of shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve the problems of small load bearing, easy aging, and damage to surrounding parts of the airbag, and achieve the change of the buffer force. , fast response and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

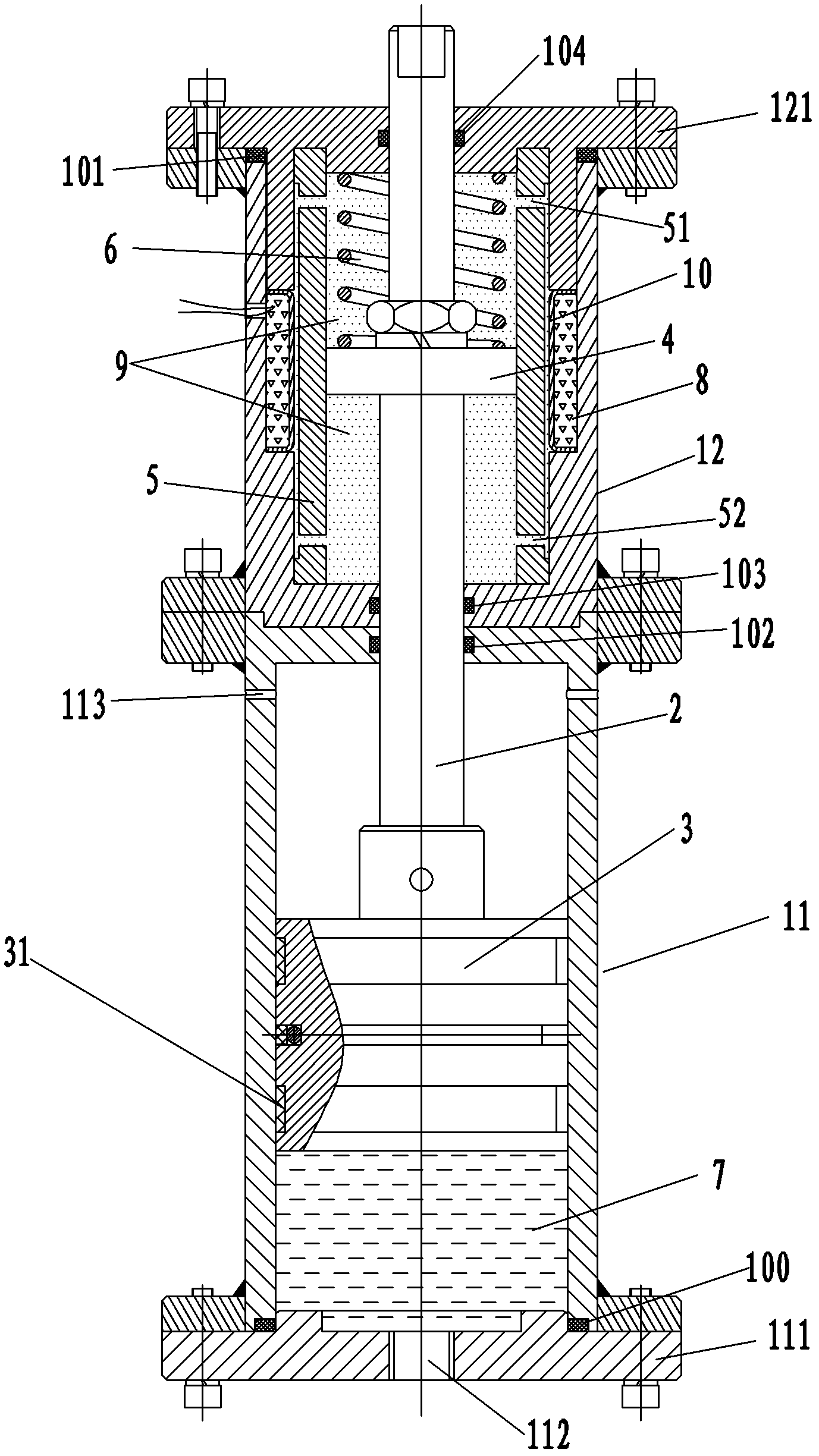

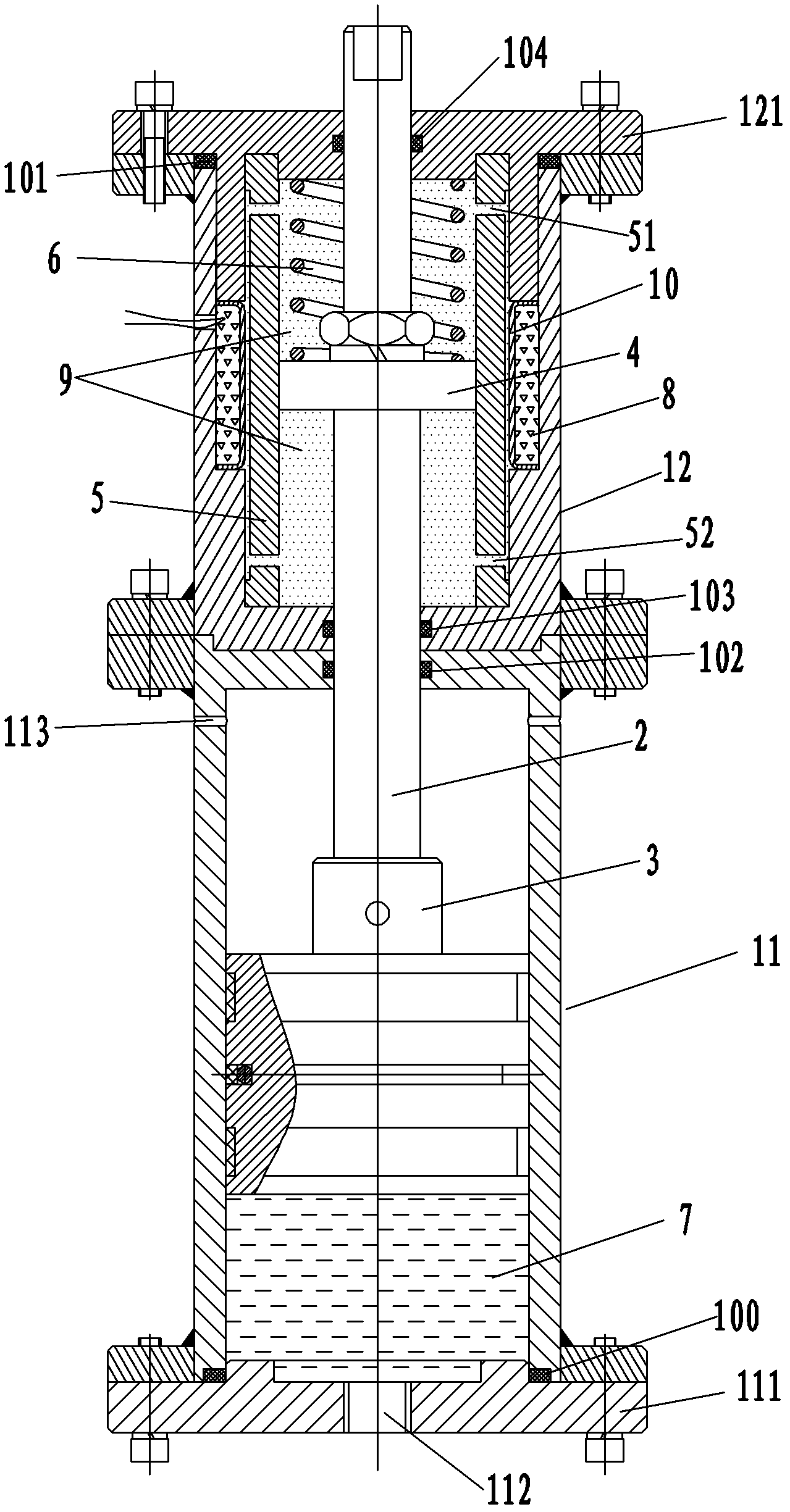

[0023] A shear type magneto-rheological buffer compensator of the present invention, such as figure 1 As shown, it includes a cylinder, a piston rod 2, a first piston 3, a second piston 4, an inner cylinder 5, a spring 6, hydraulic oil 7, an excitation coil 8, a magneto-rheological fluid 9 and a closed-loop coil installation frame 10, wherein :

[0024] The cylinder body includes a lower cylinder body 11 and an upper cylinder body 12 stacked on the lower cylinder body 11. The lower end of the lower cylinder body 11 is open, and the lower end opening of the lower cylinder body 11 is covered with a lower cylinder cover 111. The lower cylinder cover 111 is locked on the lower cylinder body 11 by hexagon socket bolts, and the lower cylinder cover 111 is protruded with a first closed ring protruding ring extending into the lower cylinder body 11, and the lower cylinder cover 111 and the lower cylinder body 11 The opening of the lower end is sealed by an O-ring 100 sleeved on the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com