Method for testing dragging force of rake pipe of trailing suction dredger

A technology of a trailing suction dredger and a detection method, which is applied to force/torque/power measuring instruments, measuring devices, earth movers/shovels, etc., and can solve the impact of drag head life saving, large deviation, and difficulty in improving Problems such as high efficiency of mud suction have achieved the effects of wide application range, convenient detection and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

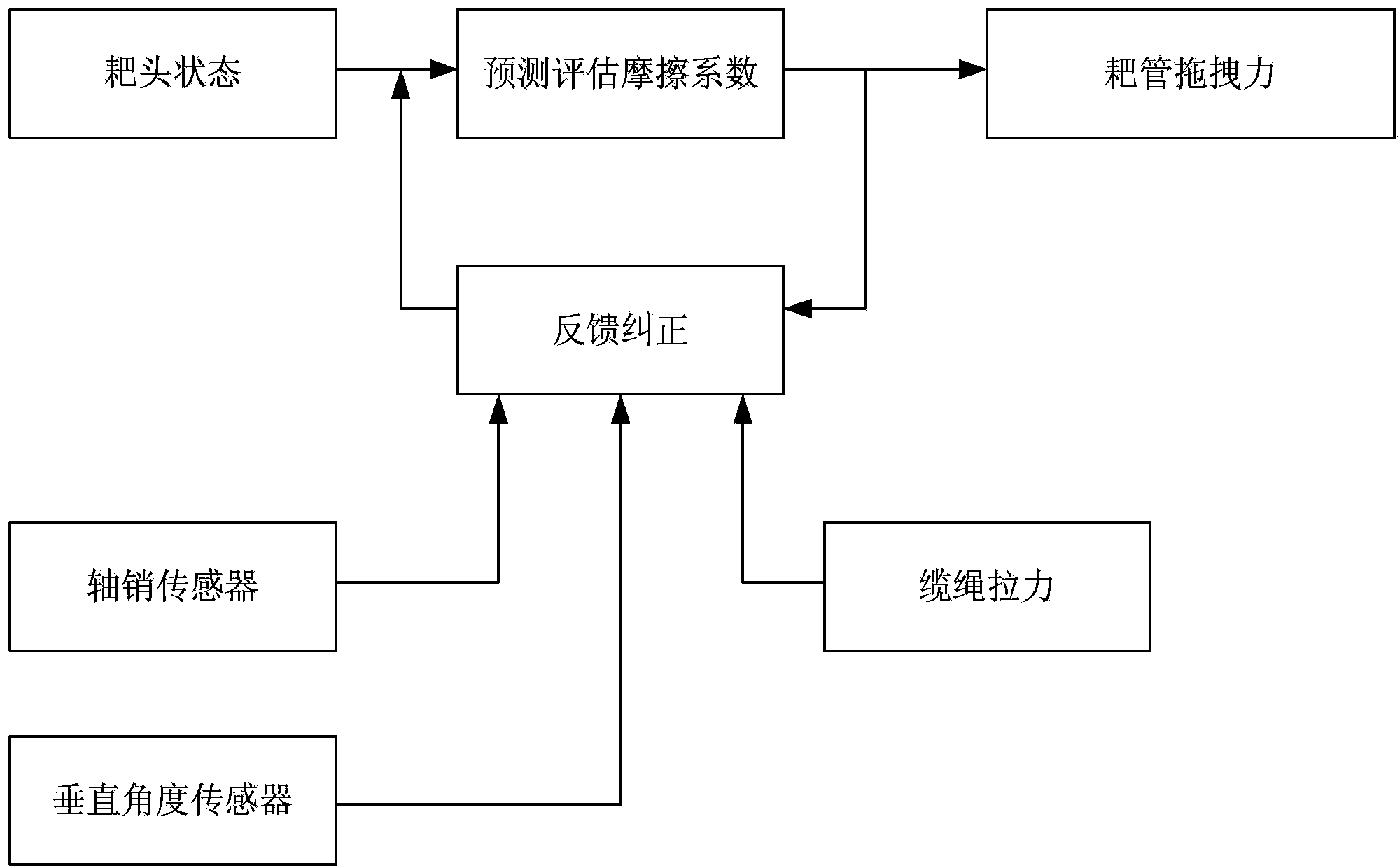

[0029] A method for detecting the dragging force of the rake tube of a trailing suction dredger, through the force balance analysis of the rake head and the rake tube, and the evaluation of the effect of the seabed friction on the rake head during the process of rake suction, how to reduce the drag force of the rake Effective and reasonable estimation of the resistance of the head on the seabed.

[0030] The information collection system of the trailing suction dredger is used to obtain the physical quantities of various evaluation indicators of the raking state, including the pin sensor at the joint of the raking pipe, the angle encoder at the joint of the raking pipe, the angle encoder at the joint of the cable, and the distance between the cable and the pipe. The physical quantity data collected by the force sensor and wave compensator of the rake head.

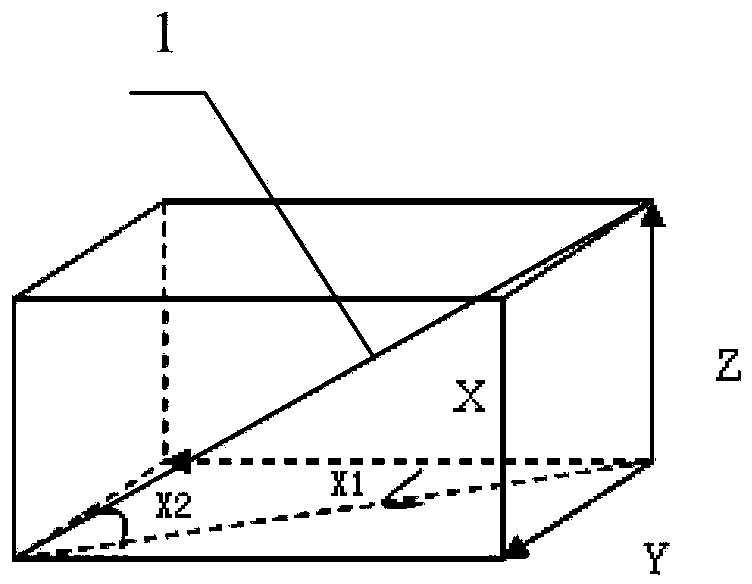

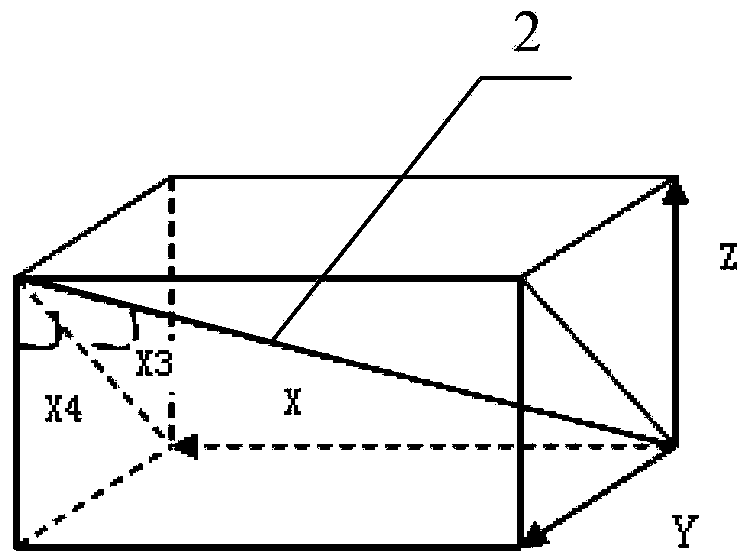

[0031] The physical quantities obtained by the information collection system of the trailing suction dredger include: th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com