A permanent magnet motor

A permanent magnet and unified technology, applied in the direction of magnetic circuits, electrical components, electromechanical devices, etc., can solve problems such as failure to achieve, and achieve the effect of improving electromagnetic torque and reducing torque fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

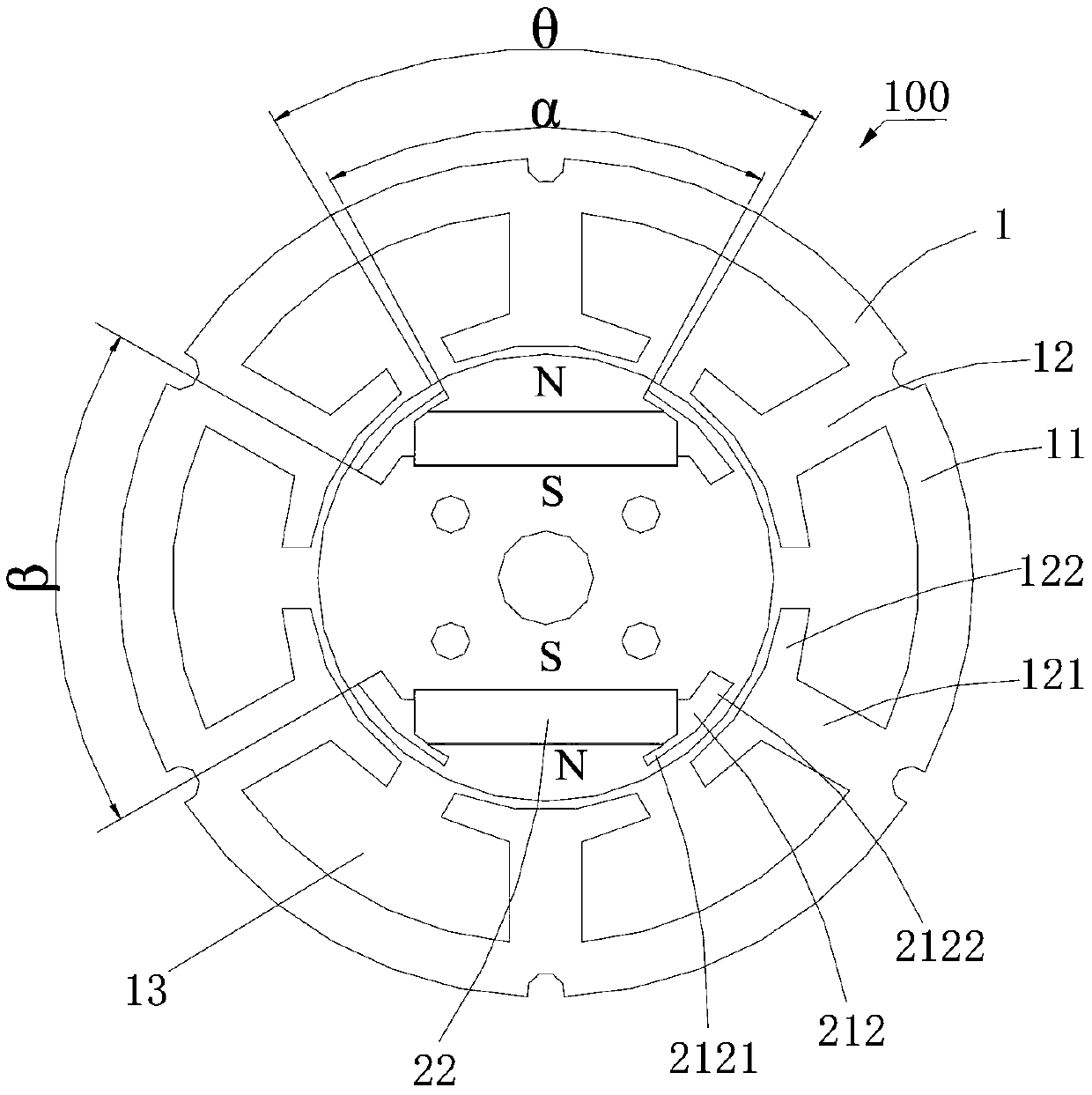

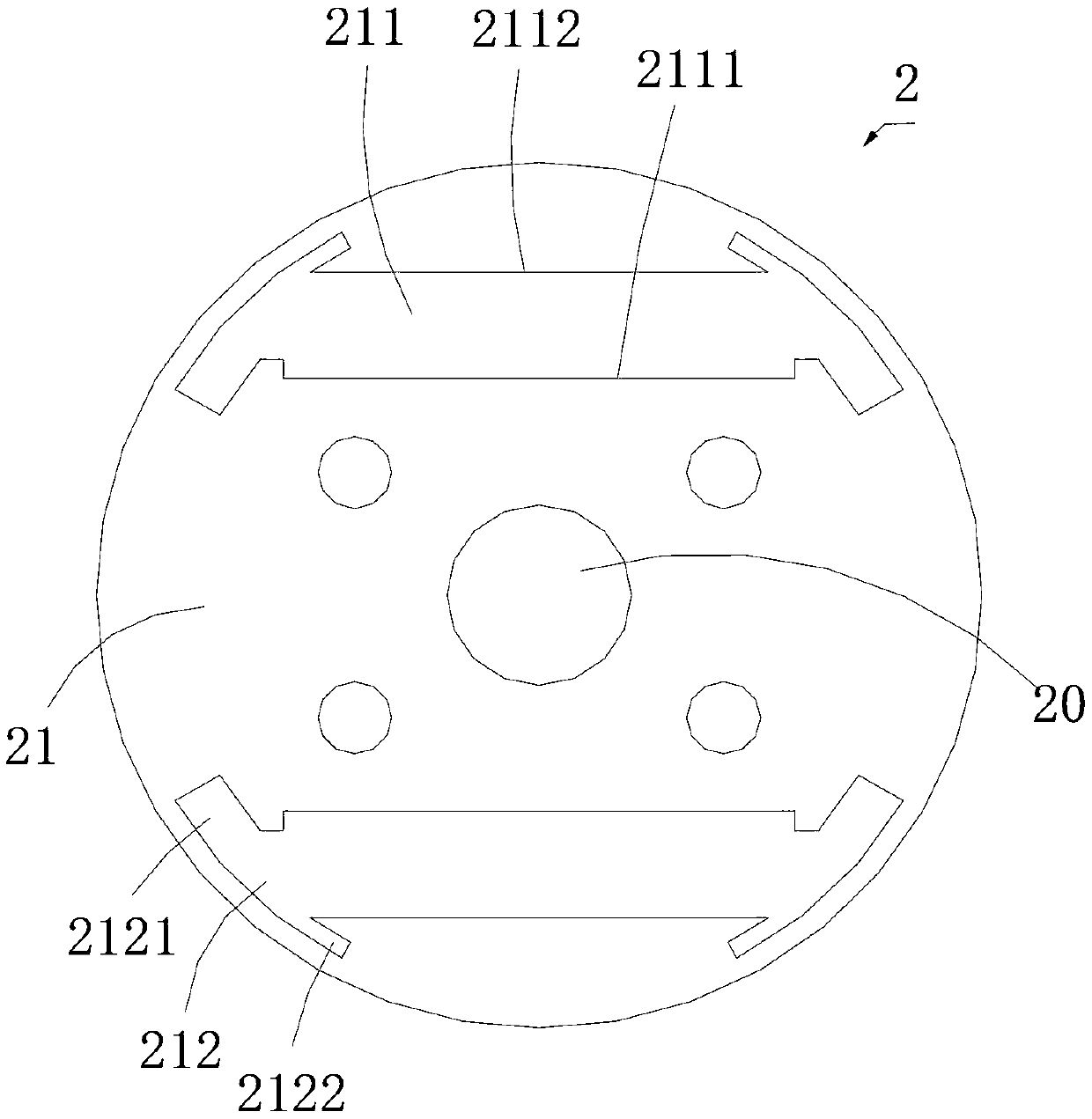

[0020] Please refer to 1 to figure 2 , a permanent magnet motor 100 according to the first embodiment of the present invention, which includes a stator 1 located outside and a rotor 2 located inside the stator 1 .

[0021] In this embodiment, the stator 1 includes an outer edge portion 11 located at the periphery, a plurality of stator teeth 12 extending from the inner surface of the outer edge portion 11 to the center of the outer edge portion 11 , and winding slots 13 between the stator teeth 12 . The outer edge portion 11 is annular, and the stator tooth 12 includes a winding portion 121 connected to the outer edge portion 11 and pole shoes 122 extending from the end of the winding portion 121 to both sides. The stator teeth 12 and winding slots 13 are evenly distributed inside the outer edge portion 11 , and the pitch between two adjacent stator teeth 12 and the slot pitch between two adjacent winding slots 13 are θ degrees. In this embodiment, the number of stator teeth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com