Consequent-pole motor and compressor with same

A technology of alternating poles and polarities, which is applied to electrical components, electromechanical devices, electric components, etc., and can solve problems such as asymmetry, fluctuations, and small reluctance torque between adjacent magnetic poles of alternating pole motors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

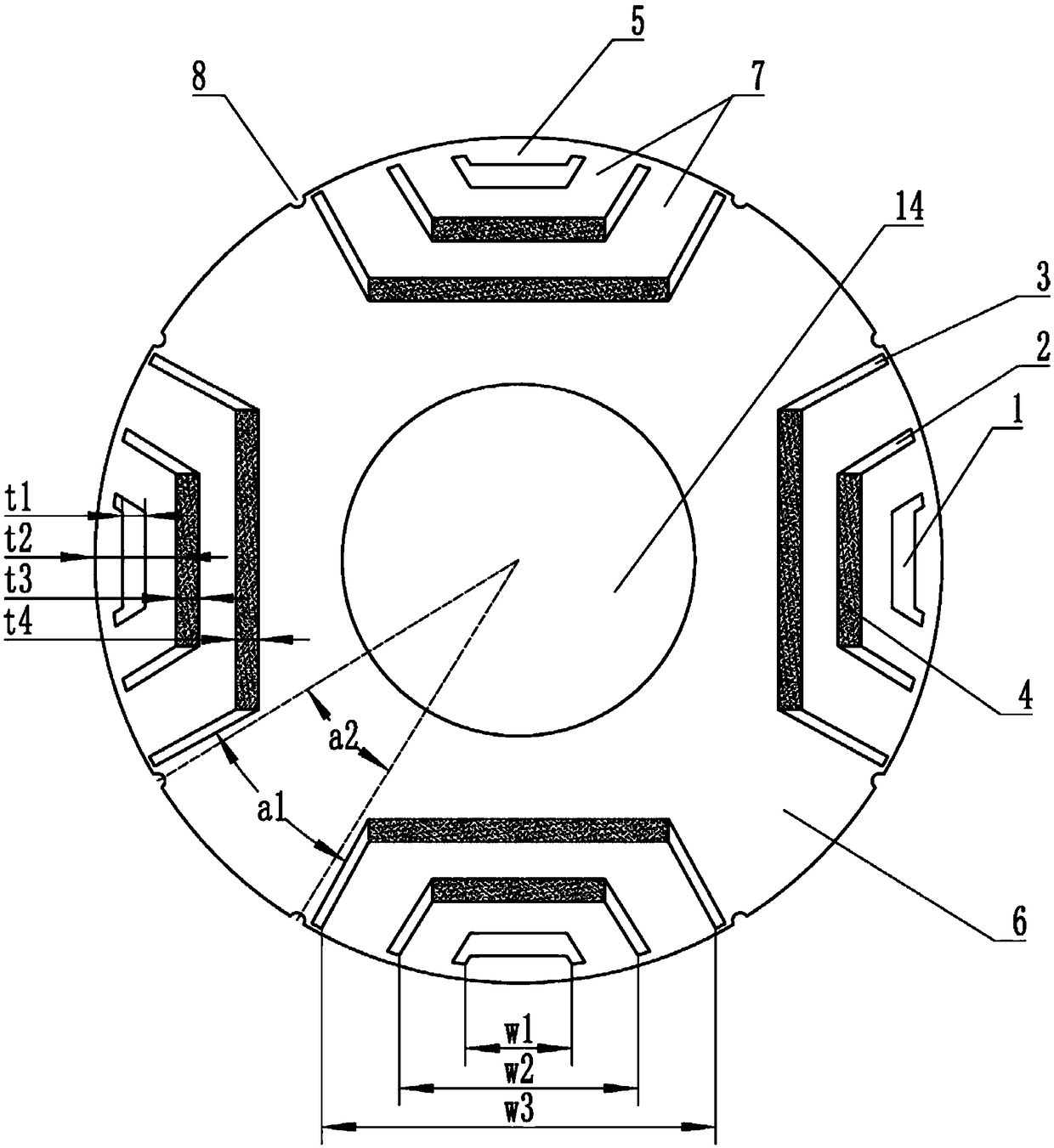

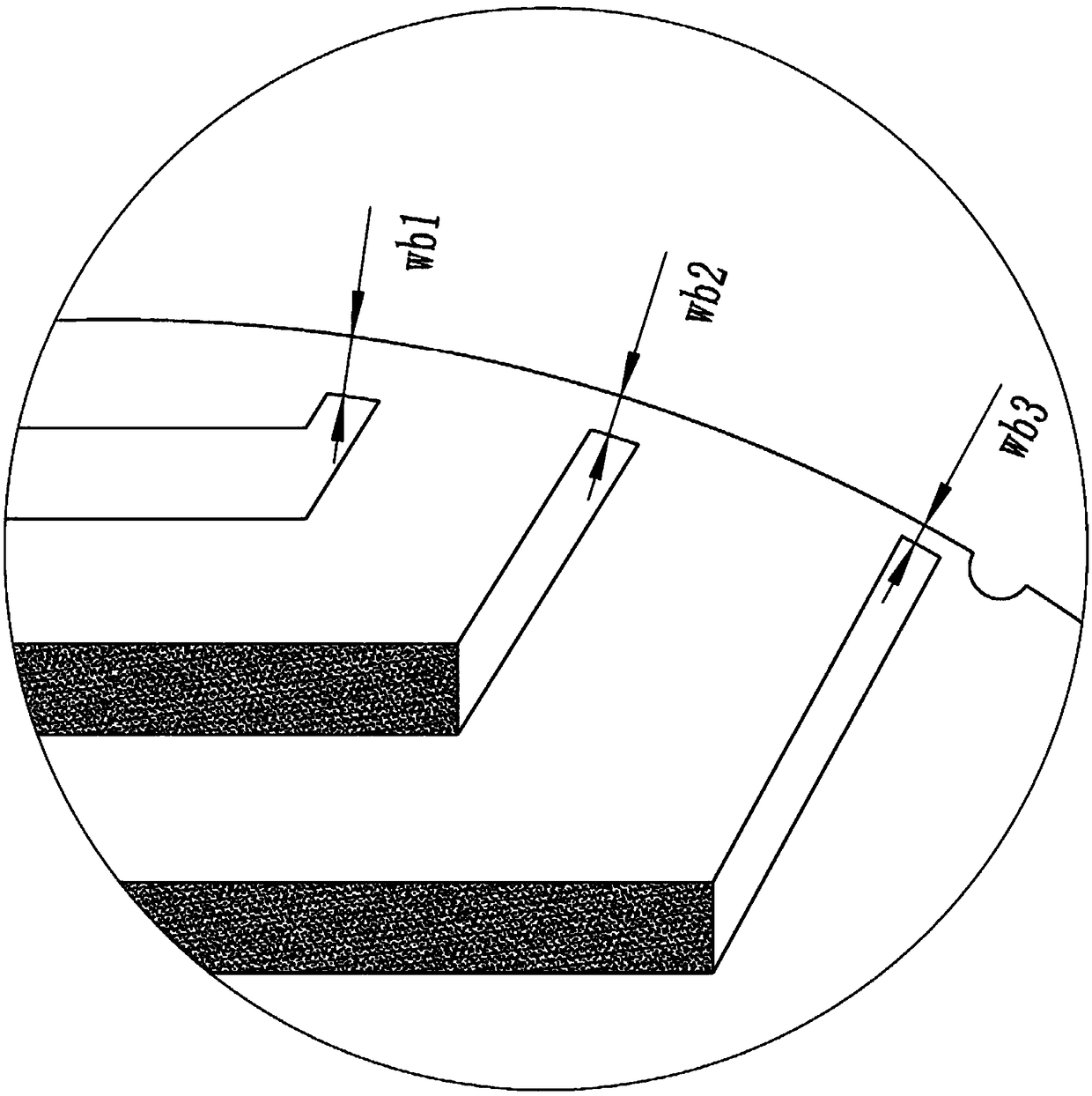

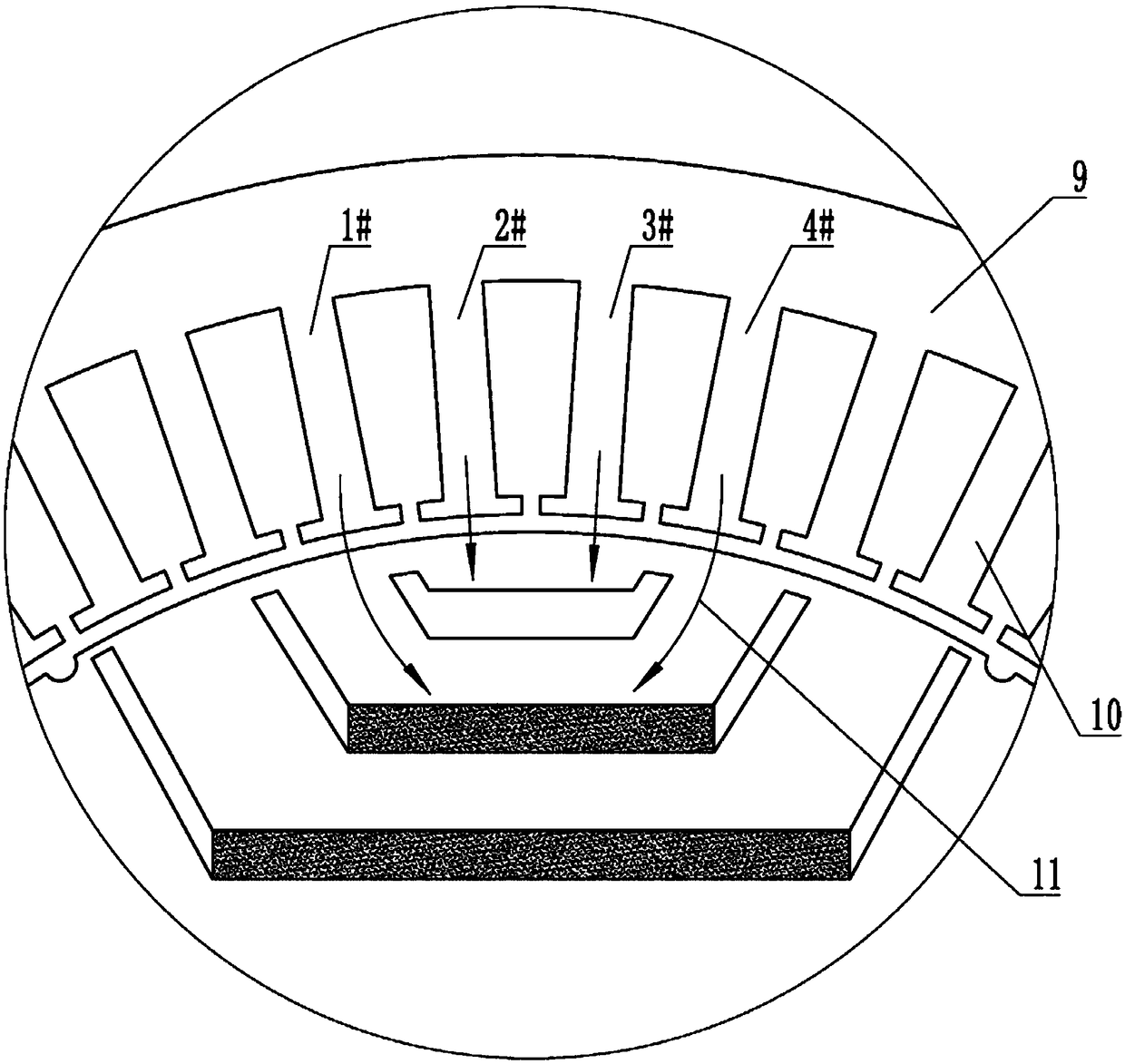

[0041] An alternating pole permanent magnet motor includes a rotor and a stator. figure 1 Shown is the schematic diagram of the rotor structure. There are four sets of slot groups on the rotor, and each set of slot groups is composed of three layers in the radial direction. There is no permanent magnet installed in the slot 1 of the first layer, and the slots (2, 3) of the second layer and the third layer Permanent magnets 4 are installed, and the polarities of all the permanent magnets facing the outer periphery of the rotor are the same polarity, and the sectors where the permanent magnets are located are generally called permanent magnet poles 5 . The soft magnetic material between the different sets of slots is magnetized to the opposite polarity of the permanent magnets, called alternating poles 6 .

[0042] The slots are arranged in three layers, which can be understood as adding a layer of air slots outside the two layers of permanent magnets, adding such Figure 4 Th...

Embodiment 2

[0065] Permanent magnets are installed in the slots 1 of the first and third layers of the rotor, and no permanent magnets are placed in the slots of the second layer. Other settings are the same as in Example 1.

Embodiment 3

[0067] A compressor comprising the alternating pole motor in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com