Wet-type high pressure resistant torque motor

A high-pressure resistant technology, applied in the field of electrical-mechanical conversion mechanism, can solve the problems of being easily eroded by oil, scrapping, and affecting the normal operation of the torque motor, and achieves the effect of simple and reliable high-pressure-resistant structure without welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

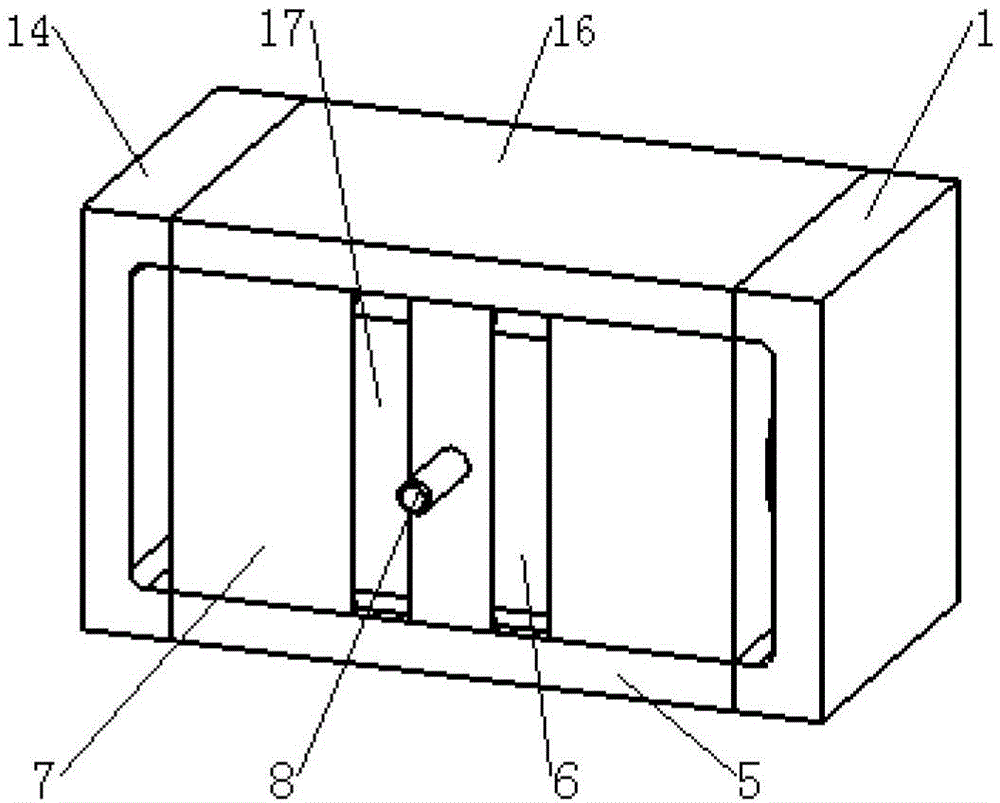

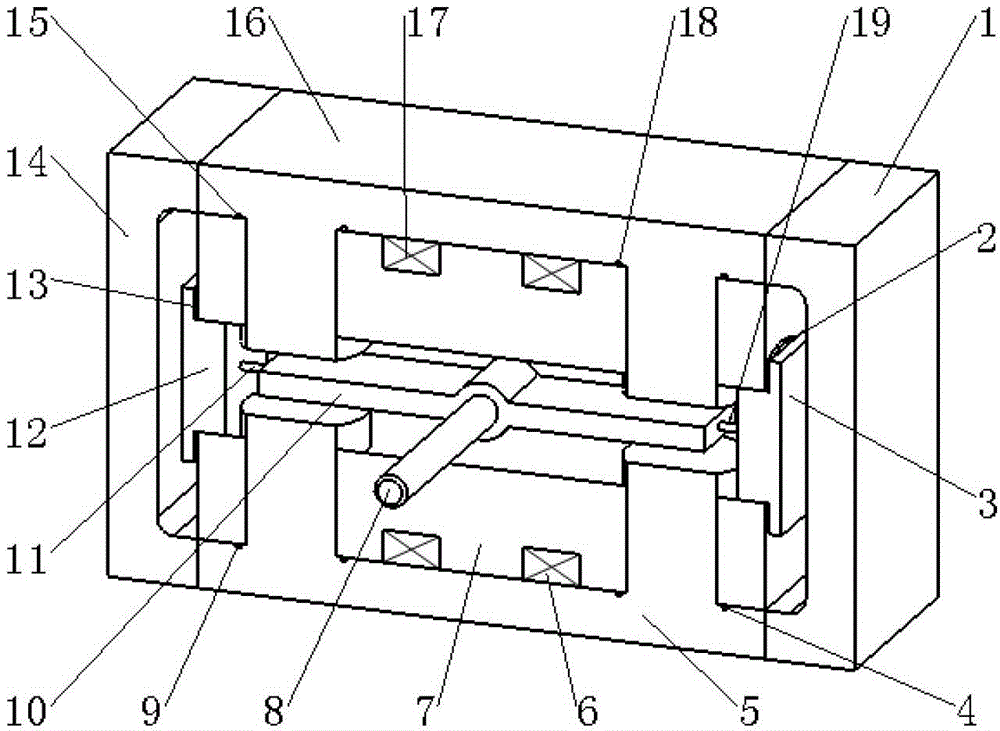

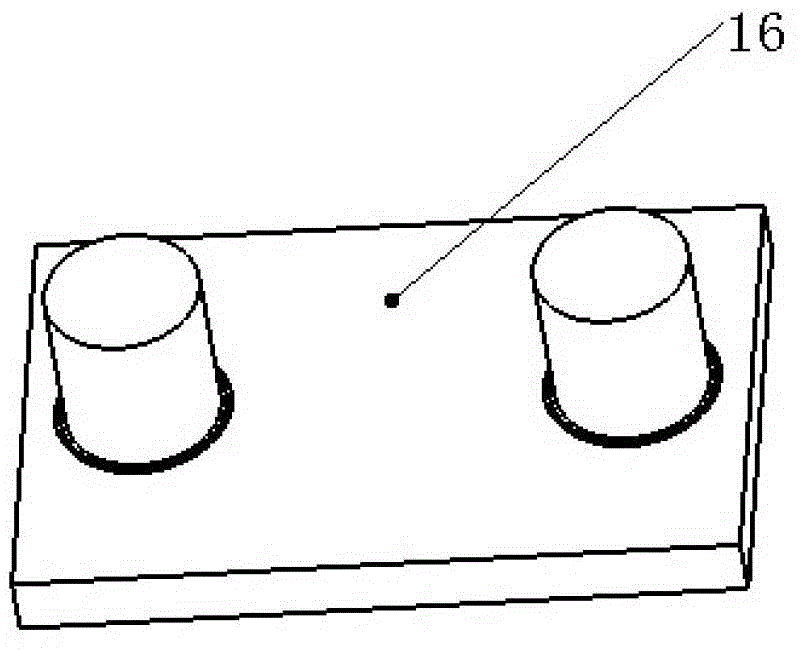

[0022] Attached below figure 1 -7 further describe the present invention:

[0023] A wet high-pressure torque-resistant motor includes an armature part and a yoke part. The armature components include an armature housing 7, an armature 10, an armature push rod 8, a first spring rod 19, a second spring rod 11, a first screw plug 3, a second screw plug 12, a first control coil 6 and a second control coil Coil 17, etc., one end of the armature push rod 8 is fixedly connected with the armature 10, and one end is used to directly connect with the main valve core of the servo valve; in order to form a wet structure, the armature 10 and the armature push rod 8 are sealed in the armature filled with oil cavity; the armature 10 is flat and long, and the armature 10 can rotate around the axis of the armature push rod 8 within a certain angle range. In addition, it can also move along the axial direction of the rotating shaft with the valve core. The structure is very suitable as an el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com