High pressure resistant rotary electromagnet with low inertia

A rotating electromagnet, high-voltage technology, applied in the direction of electromagnets, electrical components, electromechanical devices, etc., can solve the problem of inability to work in wet state, and achieve the effect of maintaining accuracy, fast response speed and long system life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

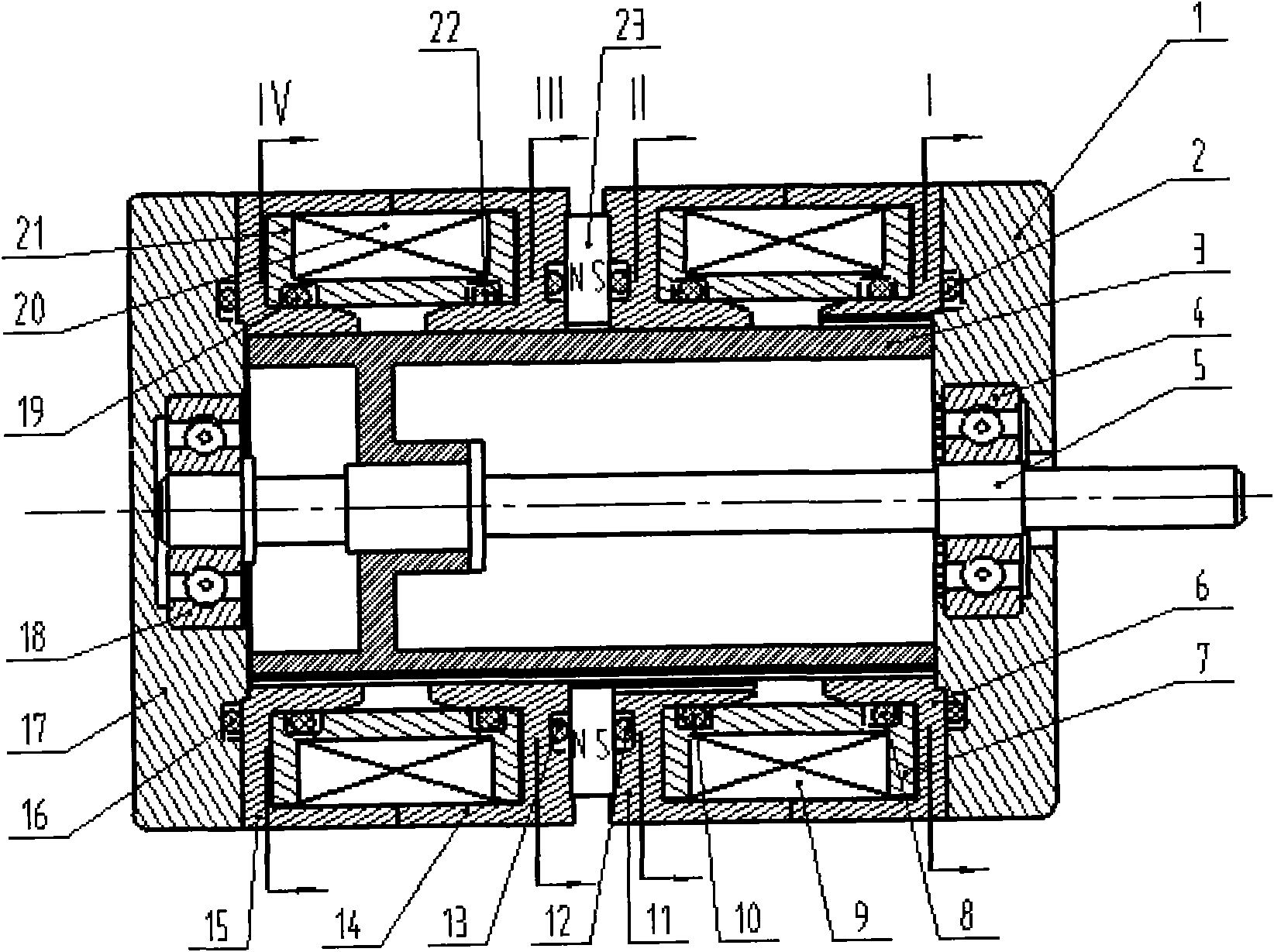

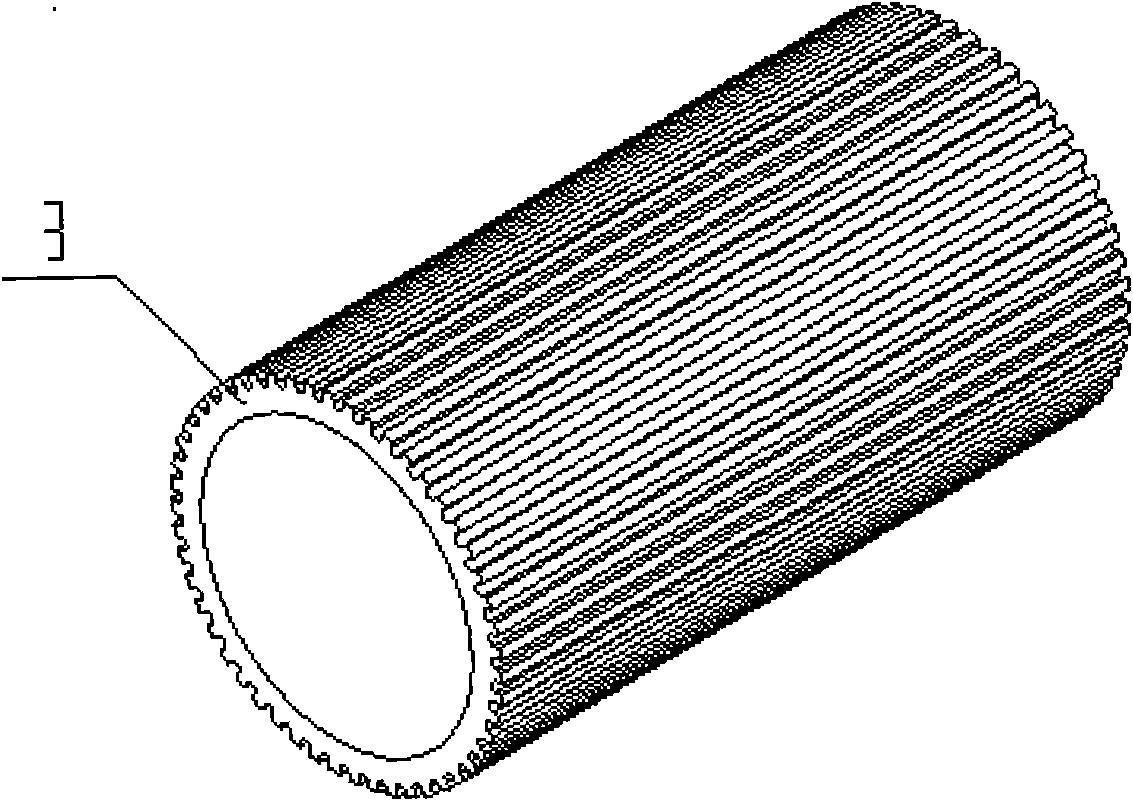

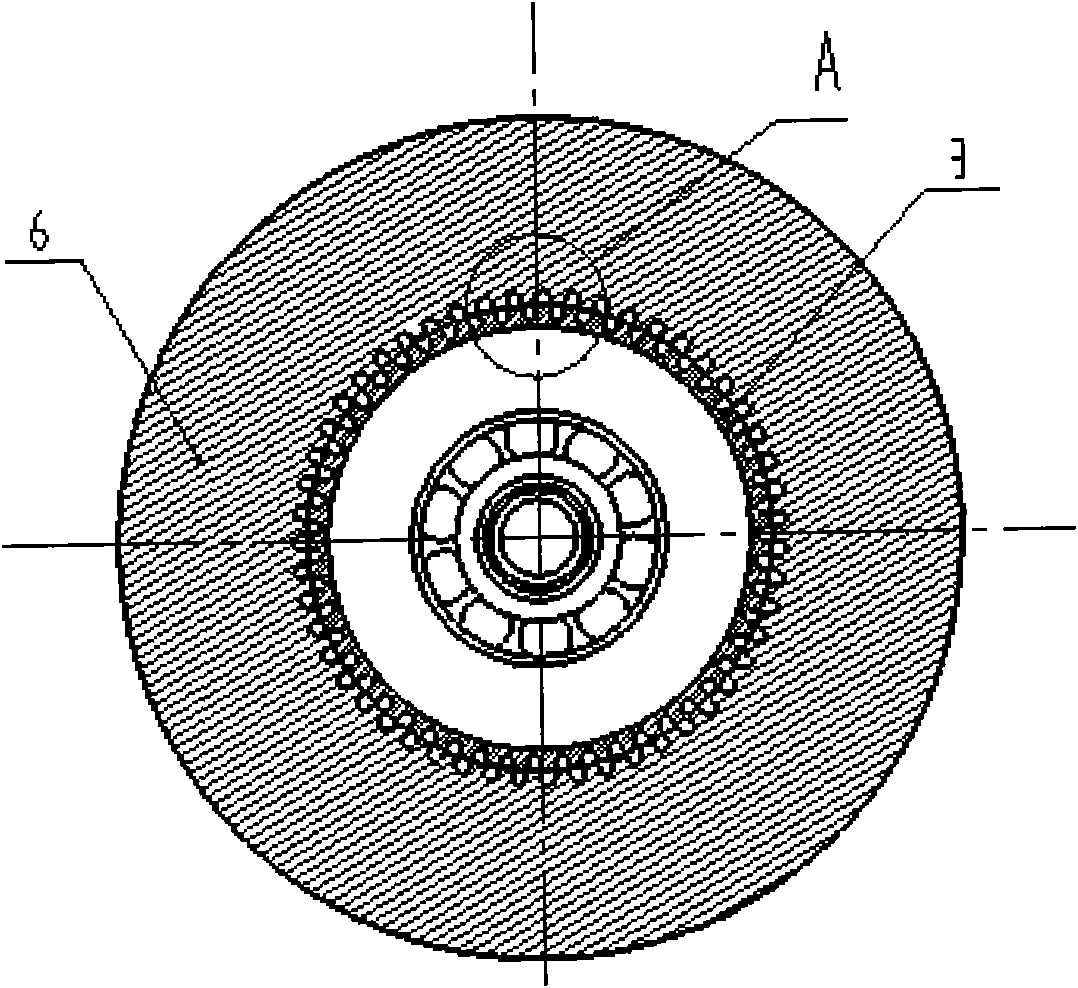

[0021] refer to Figure 1 ~ Figure 4e , a high-pressure-resistant low-inertia rotating electromagnet, including a stator part, a rotor part, a front end cover 1 and a rear end cover 17, the stator part is located outside the rotor part, the rotor part includes a rotor and a rotor shaft, and the rotor is mounted on On the rotor shaft 5, the two ends of the rotor shaft 5 are installed on the front end cover 1 and the rear end cover 17 respectively, and the stator components include a first stator core 6, a second stator core 11, a third stator core 14, The fourth stator core 15, the first magnetic isolation ring 7, the second magnetic isolation ring 21, the first control coil 9, the second control coil 20 and the permanent magnet 23, the first stator core 6, the second stator core 11 , the third stator core 14, and the fourth stator core 15 are all semi-open, and the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com