Slider type Mach-number-variable spray pipe and wall determination method thereof

A technique for determining the method and Mach number, which is applied to injection devices, injection devices, etc., can solve the problems of high non-uniformity of Mach number at non-design points and poor flow field quality, and achieve simple structure, overcome flow field inhomogeneity, Easy to control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

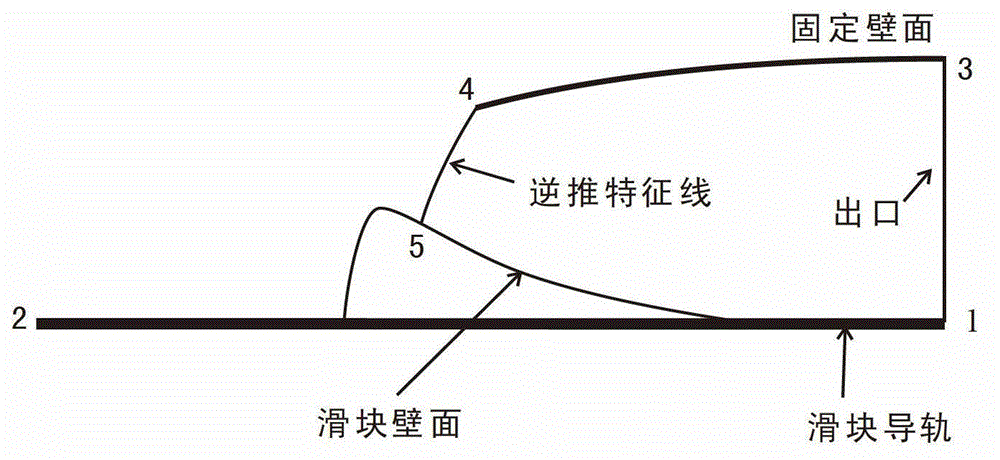

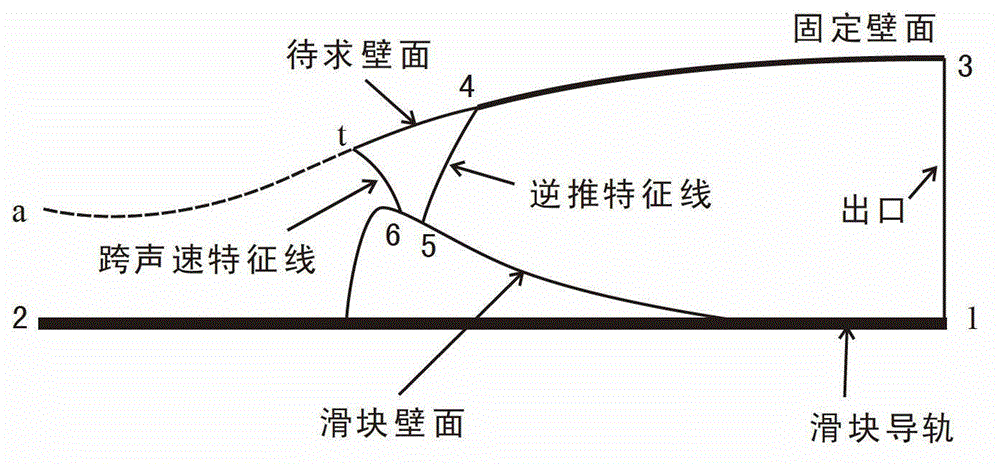

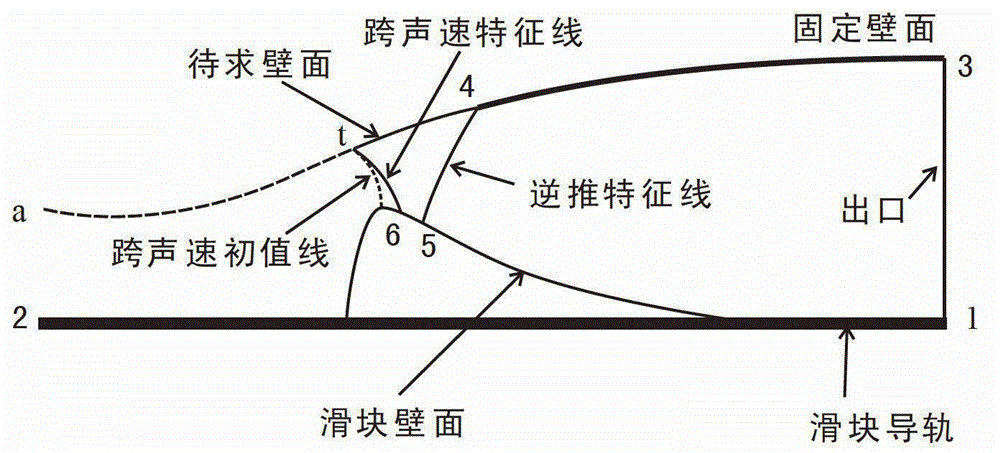

[0024] Hereinafter, the present invention will be described in detail with reference to the drawings and examples. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

[0025] In the present invention, the Mach number of the supersonic section is greater than 1.2, the Mach number of the subsonic section is less than 0.8, and the Mach number of the transonic section is between 0.8 and 1.2.

[0026] The value of the unit precession distance is selected by the vertical distance from the end point of the fixed wall curve far away from the outlet to the slider wall curve through the constraint of the expansion ratio.

[0027] According to an embodiment of the present invention, the wall surface of the slider type variable Mach number nozzle is determined by the following method.

[0028] Firstly, the relationship curve X-Ma between the precession distance of the slider ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com