Long-span high-backfill open cut tunnel structure

A large-span, open-hole technology, used in shaft equipment, shaft lining, mining equipment, etc., can solve the problems of unguaranteed durability of open-hole lining, waste of masonry, etc., to reduce heat of hydration and harmful cracks, reduce Cost, effect of reducing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

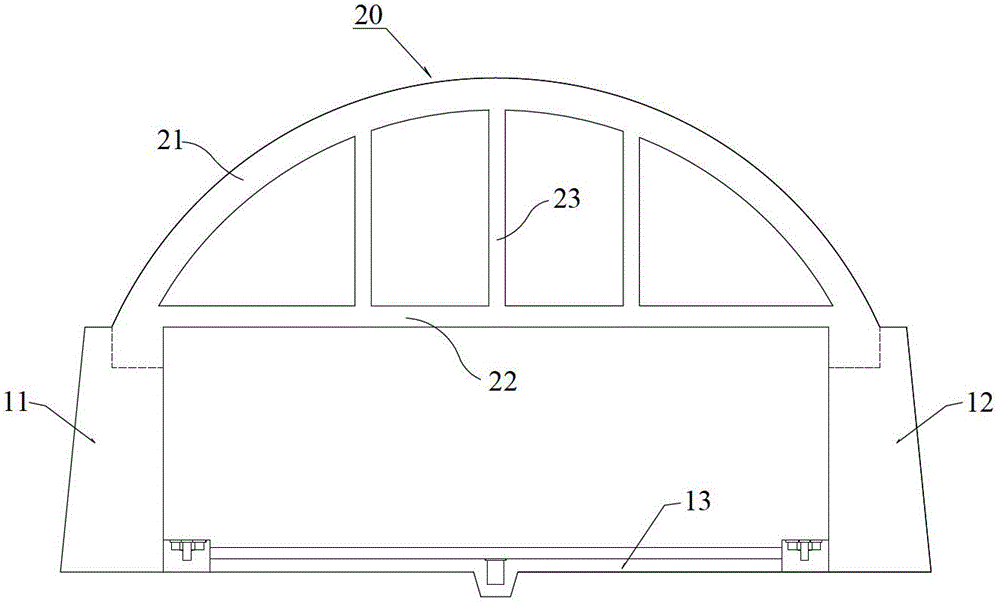

[0014] refer to figure 1 , a large-span and high-backfill open cavity structure of the present invention includes: left wall 11 and right wall 12, which are respectively poured on the lateral sides of the open cavity section; bottom plate 13, which is poured between the lower ends of left wall 11 and right wall 12; truss arch The roof 20 is a reinforced concrete structure, which is arranged on the upper ends of the left wall 11 and the right wall 12 and is integrated with them. Compared with the traditional arched open hole lining structure, it has the following advantages: the vertical bending rigidity of the section is large, and the mechanical properties of the material can be better exerted under the condition of large bending moment, which can be flexibly changed according to the magnitude of the force The rigidity and section characteristics of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com