Target control method and control system of liquid-type on-line autobalance device

A technology of automatic balancing and control method, applied in the direction of balancing rotating body, rotating vibration suppression, etc., can solve the problem of inability to accurately orient and eliminate unbalanced vibration, the sequence of liquid or gas injection, and the difficulty of accurately matching the dynamic balance state of rotating equipment. problem, to save balancing time and avoid misalignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

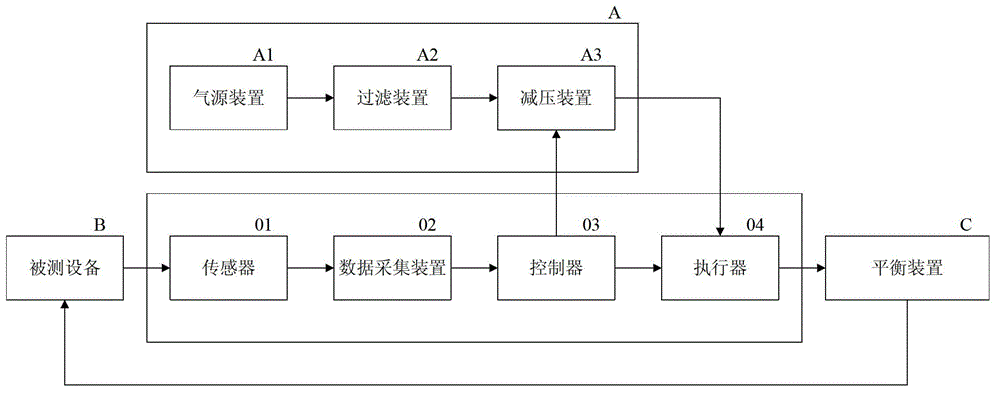

[0062] Such as image 3 As shown, the embodiment of the targeted control system includes a sensor 01, a data collector 02, a controller 03, and an actuator 04,

[0063] Sensor 01 is used to collect the vibration state of the equipment under test B under working conditions, and generate real-time vibration signals of the equipment under test B;

[0064] The data collector 02 is used to provide a signal transmission channel and transmit real-time vibration signals;

[0065] The controller 03 is used to receive real-time vibration signals, locate the vibration source according to the built-in data processing model, convert the state data of the vibration source into suppression data to offset the unbalance, and convert the suppression data to change the liquid in the liquid storage chamber of the balance device C Distributed control parameters to generate corresponding drive signals;

[0066] The state data of the vibration source includes the magnitude and phase of the unbalan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com