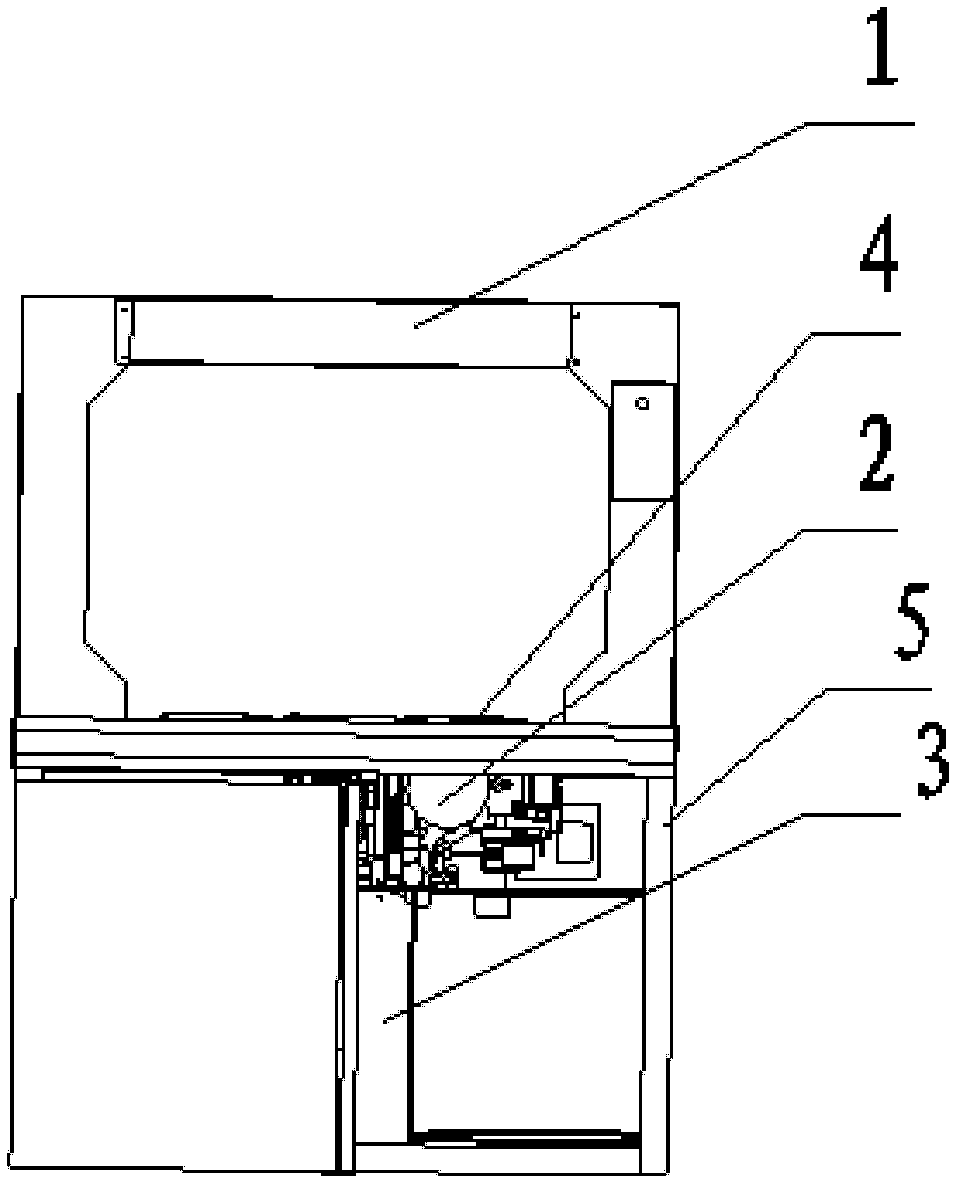

Automatic packaging mechanical equipment

A kind of mechanical equipment and automatic technology, applied in the parts and materials of strapping machinery, etc., can solve the problems of being exposed to the outside of the box, unpredictable size of packing objects, insufficient packing strength, etc., to improve efficiency and quality, fast and automatic packing effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

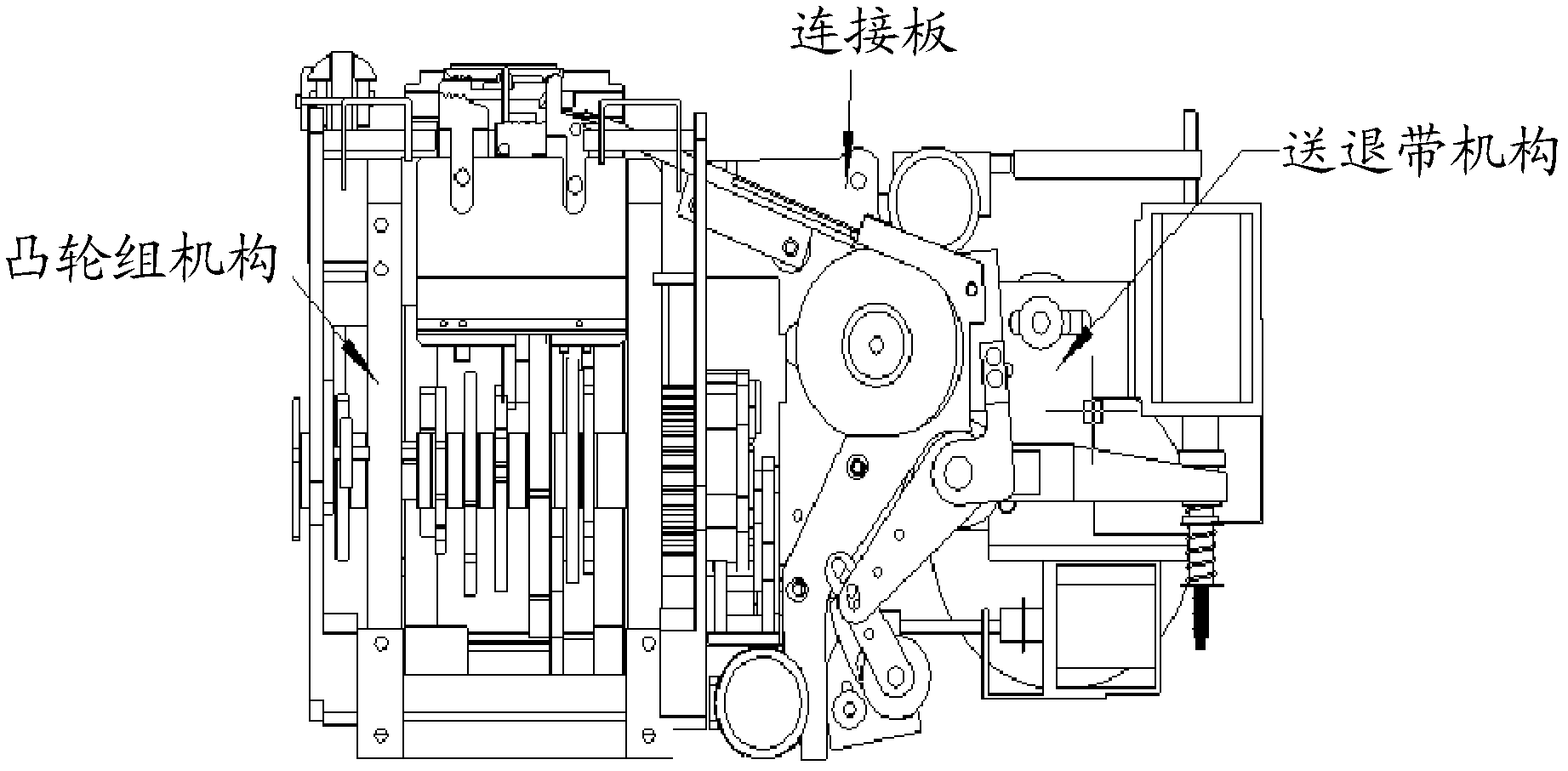

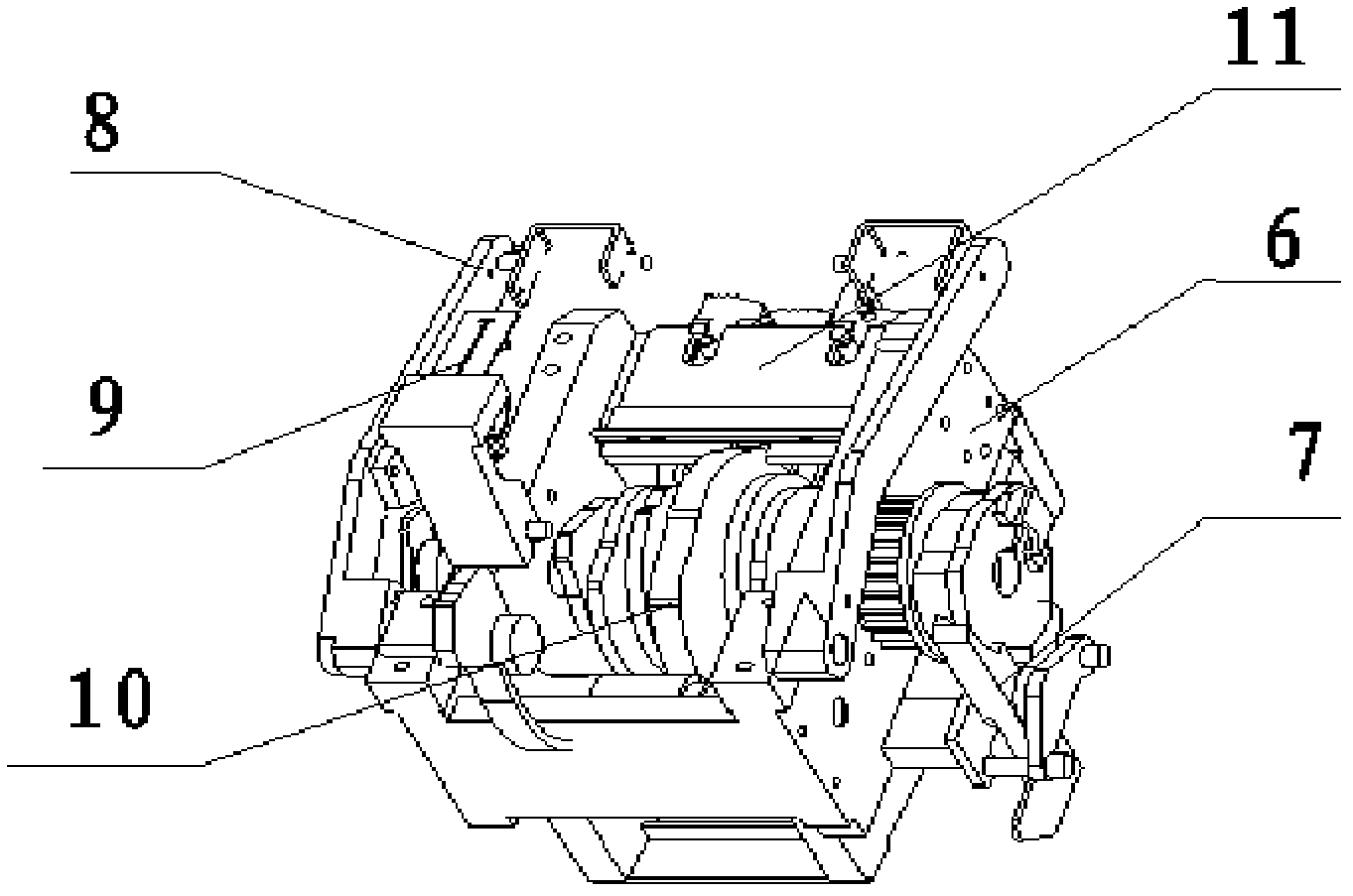

[0032] The specific implementation manners of the present invention will be described in further detail below with reference to the accompanying drawings. Those of ordinary skill in the art should understand that the following examples are only schematic illustrations of the technical solutions of the present invention, and preferably introduce the specific implementation of the present invention and the operation process of the fully automatic fast packing machine of the present invention, but the present invention The invention is not limited thereto.

[0033] As mentioned above, traditional baler equipment mainly adopts semi-automatic mode (that is, the combination of mechanical operation and manual mode), manually inserting the belt into the belt feeding port, and then automatically feeding the belt to the bow-shaped arch belt under the action of the mechanical mechanism. Road, and every time you pack it, you have to send it manually. In this way, the higher the number of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap