Saponin derivatives and uses thereof

A technology of derivatives and saponins, applied in furostane-type saponin derivatives, the application field in the prevention and treatment of depression, can solve the problems of no depression, rare relationship between chemical structure and pharmacodynamic mechanism, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

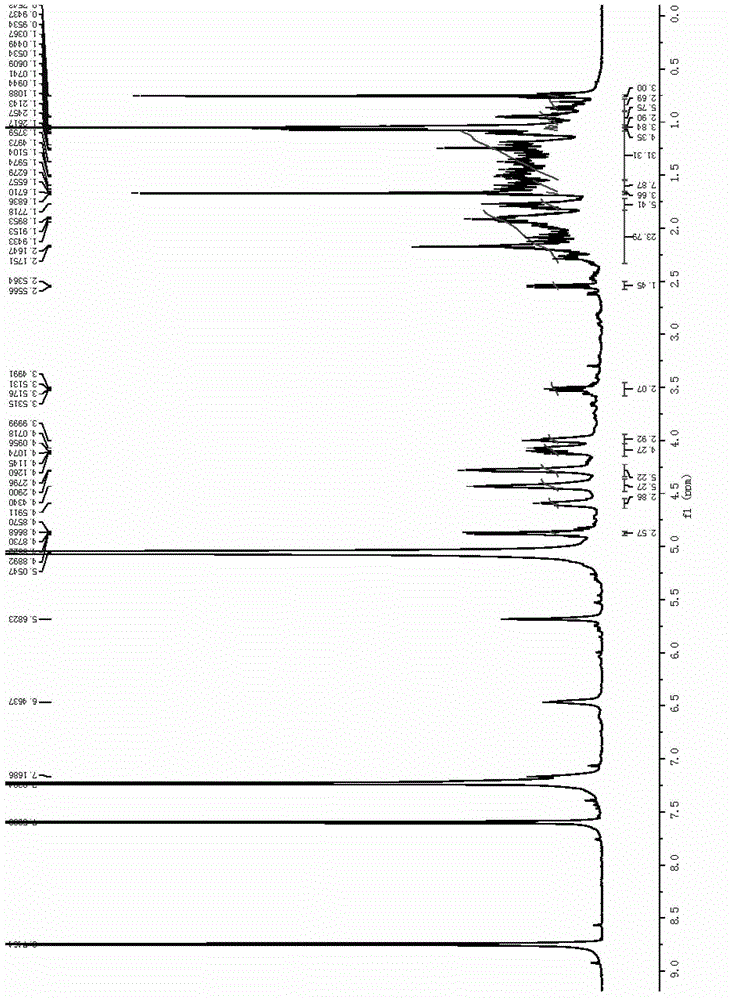

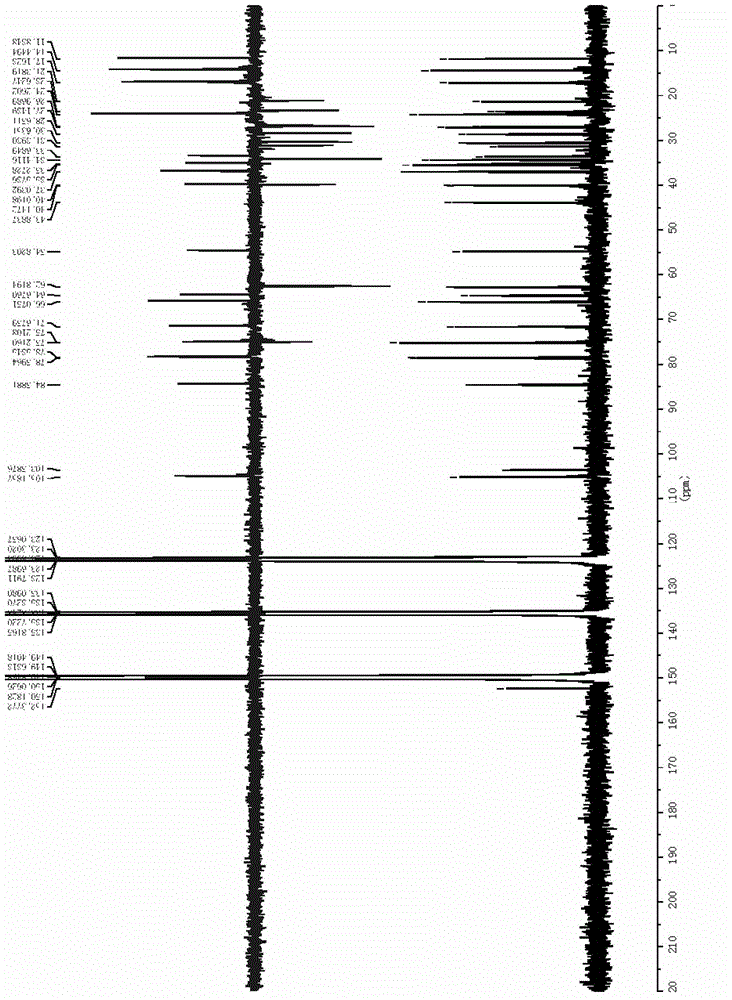

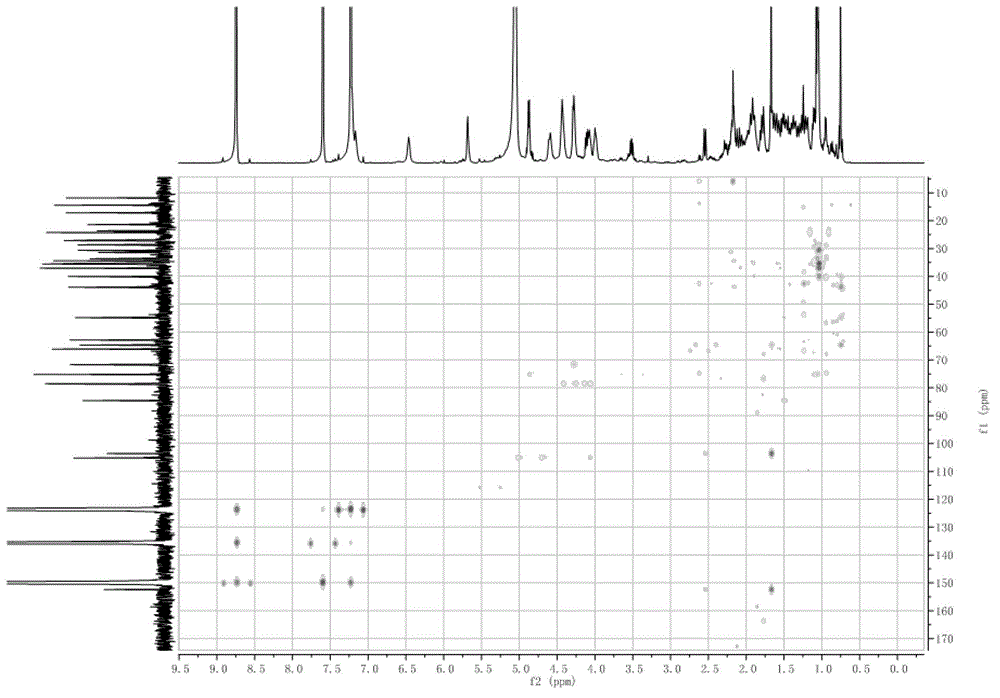

[0074] Example 1 Preparation of furostane-type saponin monosaccharide derivatives

[0075]

[0076] To prepare furostane-type saponins monosaccharide derivatives with timosaponin B-III as the reaction starting material, the specific steps are as follows:

[0077] (1) Dissolve 0.05mol Zhimu Saponin B-Ⅲ in 300ml methanol solution (water or 30v / v% ethanol solution or 1w / v% Tween solution) with a volume ratio of 10v / v%, and add 0.5ml-1ml Concentrated sulfuric acid, react at 80°C-150°C for 1 hour to 6 hours.

[0078] (2) Adjust the pH of the above reaction solution to 6-7 with sodium hydroxide.

[0079] (3) Use 900ml-1200ml n-butanol to extract the solution obtained after neutralization in step (2) for 3 times, and concentrate the extract under reduced pressure to evaporate to dryness.

[0080] (4) After dissolving the above solid with water and adsorbing the saponin on the ODS column, eluting with 40v / v%-60v / v% methanol, collect the eluate.

[0081] (5) Recover the solution under reduced pr...

Embodiment 2

[0082] Example 2 Preparation of furostane-type saponin derivatives

[0083]

[0084] (1) Dissolve 0.05mol Anemarrhena saponin B-Ⅲ in 300mL methanol solution (water or 30% ethanol solution or 1% Tween solution) with a volume ratio of 10%, add 2mL-4mL concentrated hydrochloric acid, 80-150℃ React for 1 hour to 6 hours.

[0085] (2) Adjust the pH of the above reaction solution to 6-7 with sodium hydroxide.

[0086] (3) Use 900mL-1200mL n-butanol to extract the solution obtained after step (2) neutralization for 3 times, and concentrate the extract under reduced pressure until it is evaporated to dryness.

[0087] (4) After dissolving the above solid with water and adsorbing the saponin on the ODS column, eluting it with 40v / v%~60v / v% methanol, collect the eluate.

[0088] (5) Recover the solution under reduced pressure and evaporate to dryness to obtain furostane-type saponin monosaccharide derivative 2 (NMR: see Table 1 for details).

Embodiment 3

[0089] Example 3 Preparation of furostane-type saponin monosaccharide derivatives

[0090]

[0091] To prepare furostane-type saponins monosaccharide derivatives with timosaponin B-III as the reaction starting material, the specific steps are as follows:

[0092] (1) Dissolve 0.1 mol Zhimu Saponin B-III in 600ml methanol solution with a volume ratio of 10v / v%, add 30ml-50ml concentrated hydrochloric acid, and react at 80℃-100℃ for 2 hours.

[0093] (2) Adjust to pH=6-7 with sodium hydroxide.

[0094] (3) Use 1.8L-2.4L of n-butanol to extract the solution obtained after neutralization in step (2) for 3 times, and concentrate the extract under reduced pressure to evaporate to dryness.

[0095] (4) After dissolving the above solid with water and adsorbing the saponin on the ODS column, eluting with 40v / v%-60v / v% methanol, collect the eluate.

[0096] (5) Recover the solution under reduced pressure, and evaporate to dryness to get the aglycon 3 of mother saponin B-III (NMR: 30.63(1-C); 27.14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com