Silencer clapboard and silencer

A muffler and partition technology, which is applied in the direction of mufflers, machines/engines, mechanical equipment, etc., can solve the problems of harsh howling, affecting the performance of muffler, increasing the source of noise, etc., and achieves high manufacturing pass rate and large contact area Less, the effect of stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

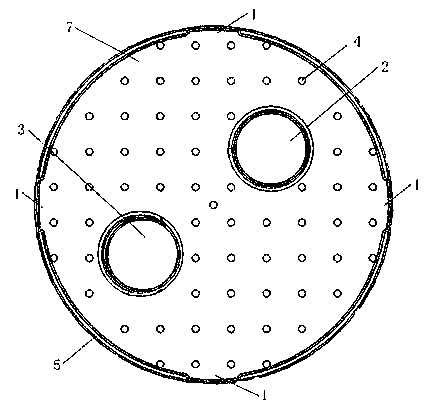

[0025] Such as figure 1 As shown, four bosses 1 are provided on the outer edge of the muffler partition 7 provided in this embodiment, and the partition 7 is provided with an air inlet pipe hole 2, an air outlet pipe hole 3, and an air diffuser hole 4; 7 is circular in shape; the four bosses 1 are evenly distributed on the outer circumference of the partition 7 .

Embodiment 2

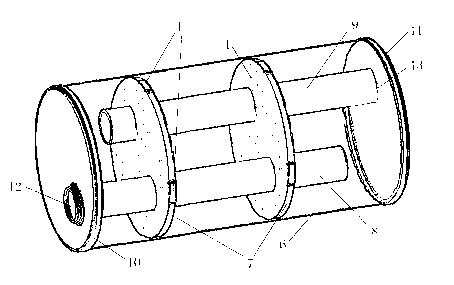

[0027] Such as figure 2 As shown, the muffler provided in this embodiment includes a housing 6 and a partition 7. The outer edge of the muffler partition 7 is provided with four bosses 1, and the bosses 1 are in contact with the inner wall of the housing 6 with an interference fit. , a gap 5 is formed between the outer edge of the partition 7 and the housing 6 except for the boss 1;

[0028] Described housing 6 comprises front end cover 10, rear end cover 11, and described front end cover 10 is provided with air inlet 12, and described rear end cover 11 is provided with air outlet 13; At least one partition 7, the partition 7 is provided with inlet pipe hole 2, air outlet pipe hole 3, diffuser hole 4; the diffuser hole 4 and the gap 5 on each partition 7 are used as the diffuser after the muffler inner partition 7 is installed. Gas part; the air inlet pipe hole 2 on the dividing plate 7 is aligned with the air inlet 12, and the air outlet pipe hole 3 on the dividing plate 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com