Microlens sheet and manufacturing method thereof

A technology of microlens arrays and lenses, applied in lenses, instruments, stereography, etc., can solve the problem of not necessarily thickness reproducibility, and achieve the effects of good reproducibility, excellent scratch resistance and dust resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0134] Working examples of the present invention are described below, but of course, the scope of the present invention is not limited to these examples.

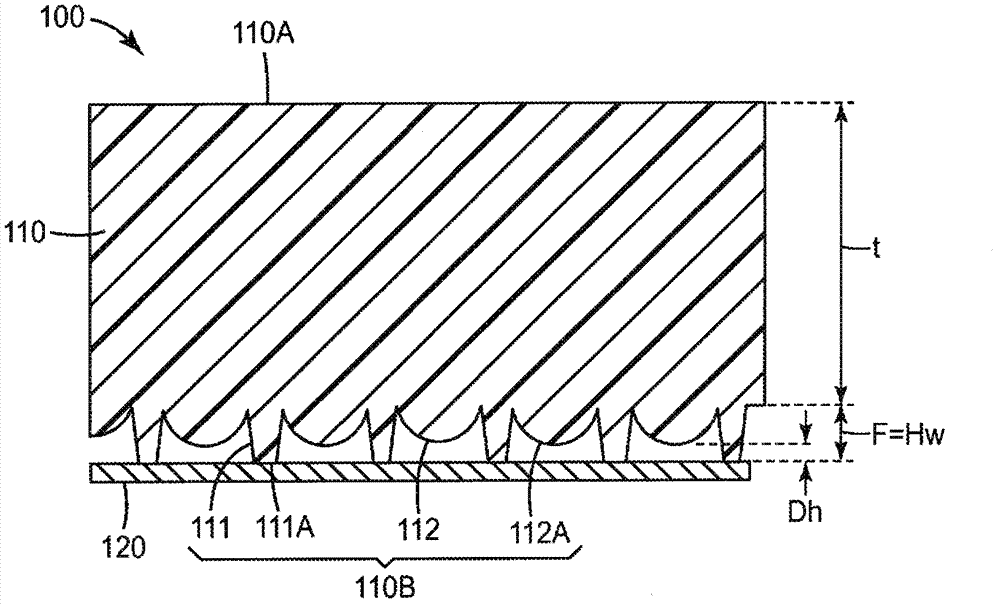

[0135] Fabrication of the microlens array layer

[0136] First, a sheet-shaped first structure body having a depressed pattern was produced by replicating air bubbles by the following procedure. As a master mold, a laminated sheet having a two-layer structure in which copper foil with a thickness of 20 μm was laminated on a polyimide layer with a thickness of 25 μm (trade name: TWO LAYER COPPER CLAD SUBSTRATE) , manufactured by Japan Interconnection Systems, Ltd.). The polyimide layer of the laminated sheet was treated with a laser to generate holes (processed by Tosei Electrobeam Co., Ltd.) in a region with a side length of 100 mm, thereby imparting a Matrix pattern of conical depressions. Fig. 6(a) is a partial cross-sectional view showing the obtained base mold, and Fig. 6(b) is a partial top view of the obtained ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com