Fixing device used in testing

A technology of fixing device and fixing column, applied in the direction of measuring device, impact test, testing of machine/structural components, etc., can solve the problem of inability to accurately find the weak point of the test piece and affect the test result, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In the following, the test fixture will be further described in detail mainly in conjunction with the accompanying drawings and specific embodiments.

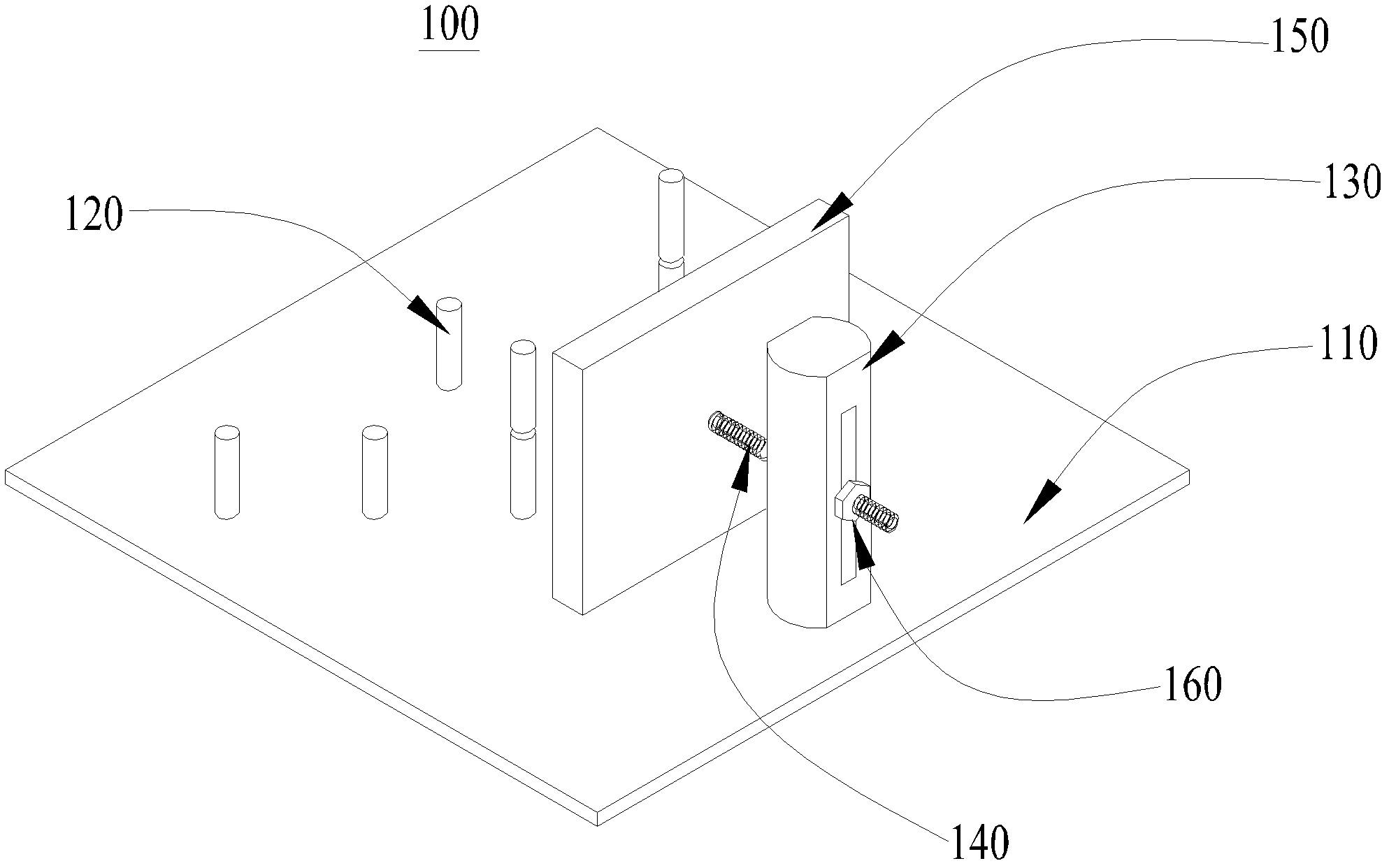

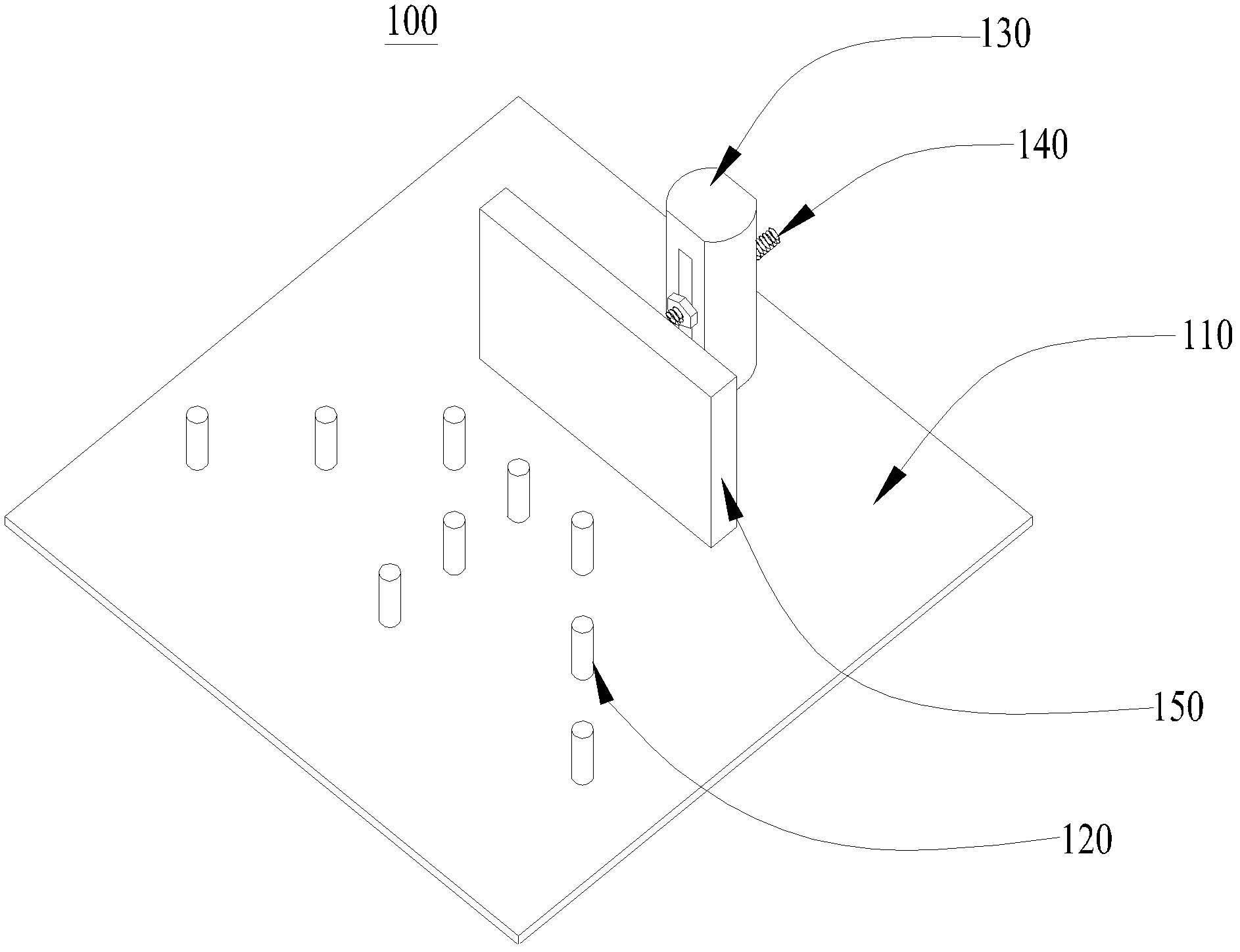

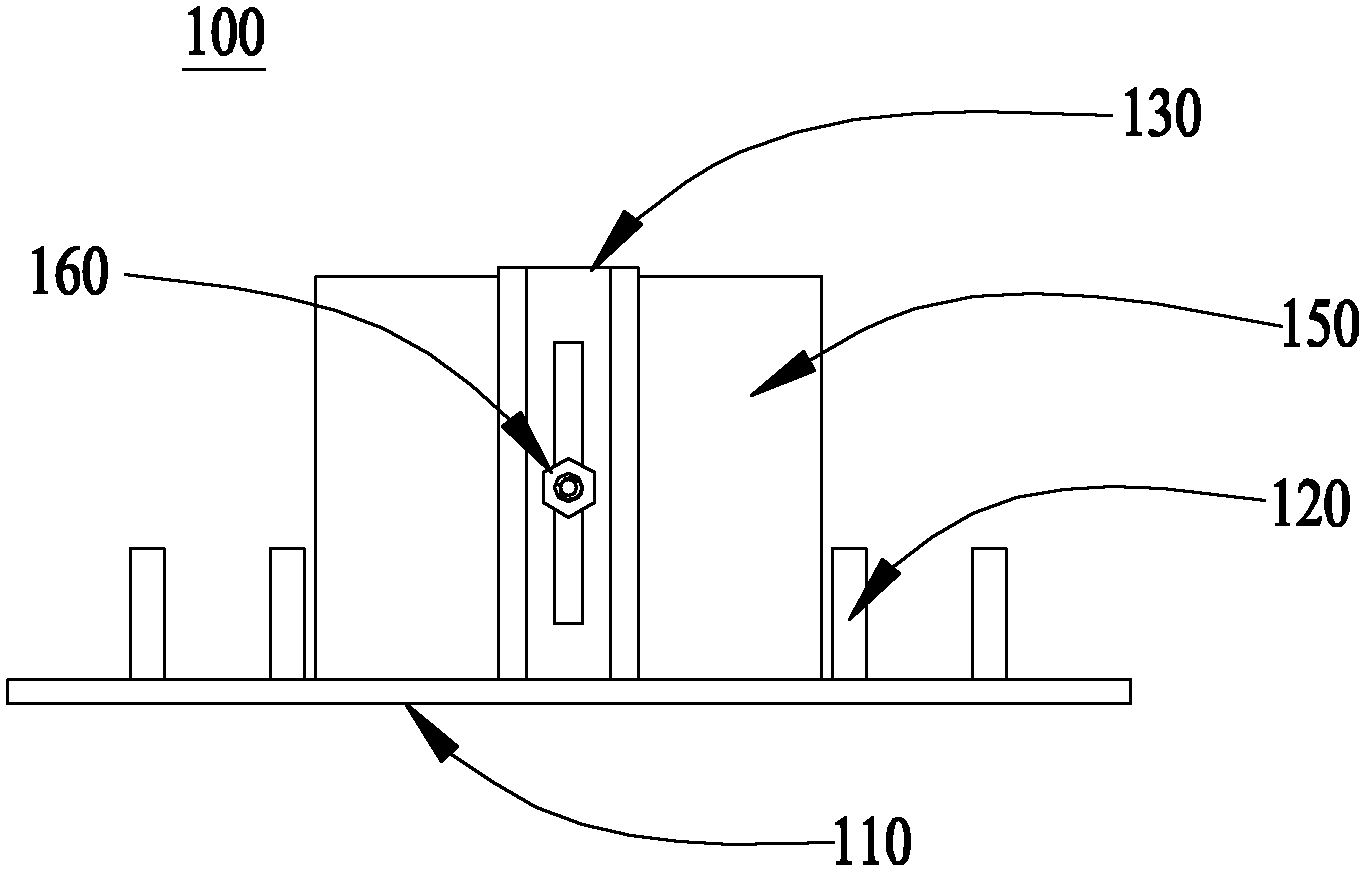

[0032] Such as Figure 1 ~ Figure 3 As shown, the test fixture 100 of this preferred embodiment is mainly used to fix the impact test piece (hereinafter referred to as the test piece) of the lamp during the impact test of the lamp, such as the lamp housing, the transparent piece, etc., so as to facilitate different angles of the impact test piece. Multi-point impact testing to find the weak point of the test piece. The test fixture 100 includes a base 110 , a first limiting component 120 , a fixing post 130 , a movable rod 140 and a second limiting component 150 . After being placed on the base 112 , the test piece can abut against between the first limiting member 120 and the second limiting member 150 to be fixed.

[0033] Wherein, the base 110 of this embodiment is preferably made of a square steel plate, such as a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com