Supercritical fluid extracting, spraying and granulating system and method

A supercritical fluid and granulation technology, which is applied in the direction of liquid droplet granulation, etc., can solve the problems of inability to monitor and operate the whole process of the process method, inability to truly measure the particle size and particle size distribution, and inability to realize real-time detection, etc. , to reduce the experimental labor intensity, save equipment investment, and shorten the experimental period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

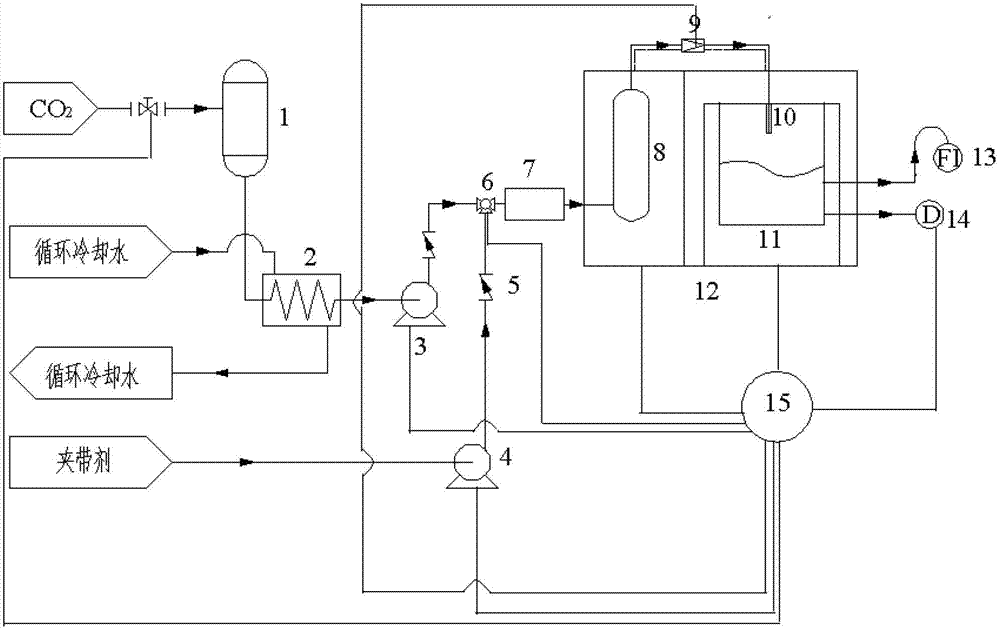

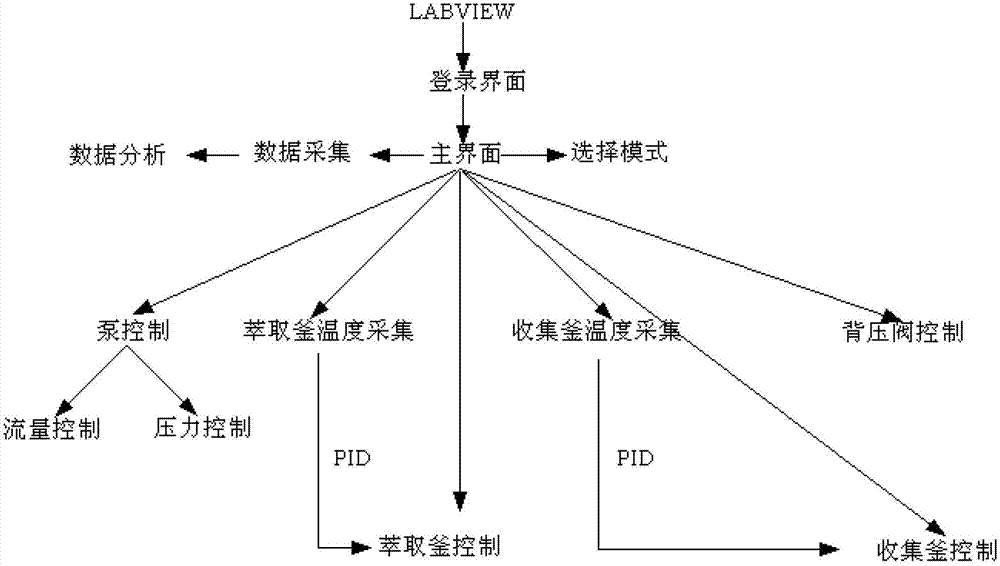

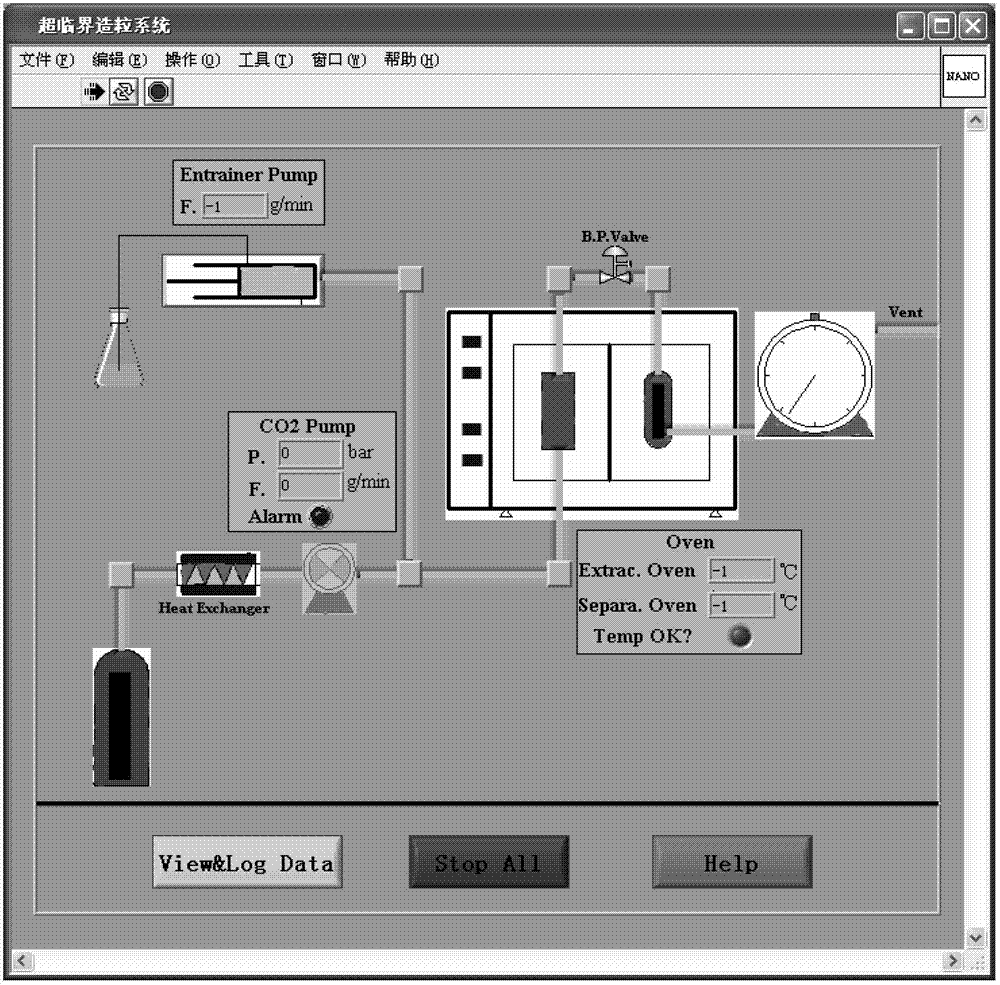

Method used

Image

Examples

Embodiment 1

[0072] Supercritical fluid extraction spray granulation technology is from AKD mixture (AKD purchased from Hebei Shijiazhuang Hengyuan Auxiliary Co., Ltd., large particles, containing C 16 AKD and C 18 AKD (Alkyl Ketene dimer: alkyl ketene dimer) particles are directly prepared in AKD:

[0073] ①Turn on the cooling heat exchanger 2 to reduce its temperature to about -5℃;

[0074] ②Fill the ground experimental materials (AKD mixture) into the extraction autoclave 8, and seal it well;

[0075] ③Check and make sure that the back pressure valve 9 is closed and the inlet valve of the high-pressure pump 3 is opened;

[0076] ④ Turn on the main power supply of the heating temperature control box 12 30 minutes before the operation and set the temperature of the extraction autoclave 8 and the collection kettle 11 (40°C) on the labVIEW software;

[0077] ⑤Open the cylinder after the temperature meets the requirements (CO 2 Pressure tank) valve;

[0078] ⑥Turn on the high-pressure pump 3, observe t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com