Halting method for scrap steel of hot rolling coilers

A coiler, hot-rolled coil technology, applied in the field of metallurgical hot rolling, can solve the problems of lack of solutions, manual lifting, equipment damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

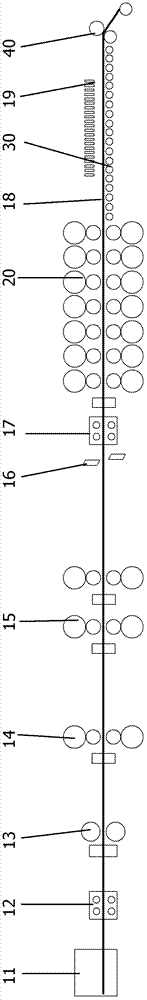

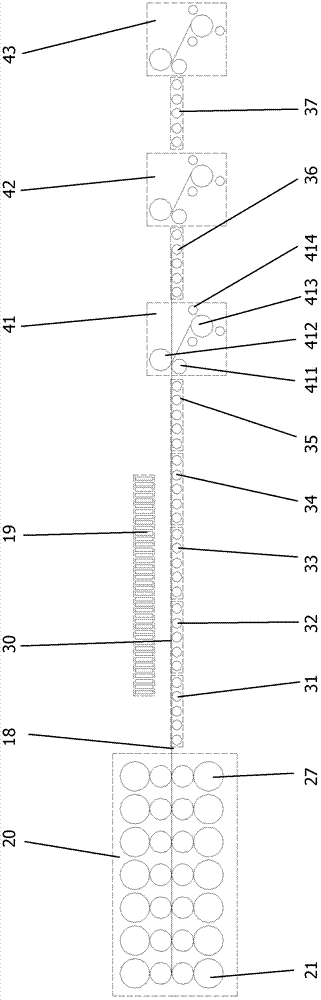

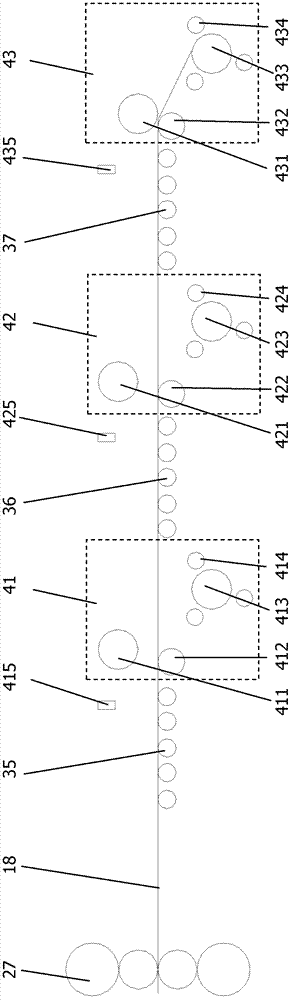

[0083] A method for shutting down scrap steel of a hot-rolling coiler, which is used for a hot-rolling production line including a finishing unit, a coiling unit and 5-15 sets of hot conveying roller tables between the two units, comprising the following steps:

[0084] The strip detection equipment for the finishing stand is installed under each stand of the finishing mill, and the strip detection equipment for detecting the actual position of the strip is installed at each coiler of the coiling unit. According to the strip detection equipment for the finishing stand And coiler strip detection equipment to detect the actual position of the strip and judge logically. When it is judged that the head of the strip has not reached the coiler, if the pinch roller of a coiler or the motor of the reel trips , Automatically switch another coiler from the standby state to the active state to avoid steel scrap accidents.

[0085] According to the strip detection equipment of the finishi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com