Hydraulic lifting platform of coal mine full-mechanized mining face

A hydraulic lifting platform and fully mechanized mining face technology, applied in the direction of lifting frames, lifting devices, etc., can solve problems such as roof caving, coal wall and roof control difficulties, and difficult maintenance operations for large mining height supports, achieving fast and convenient installation Daily maintenance work, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

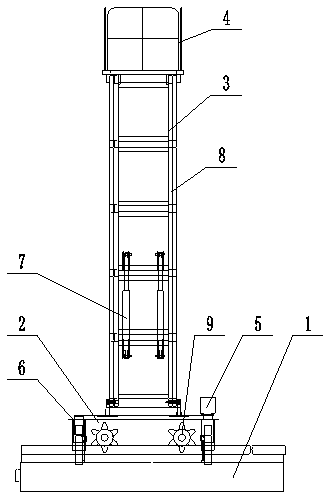

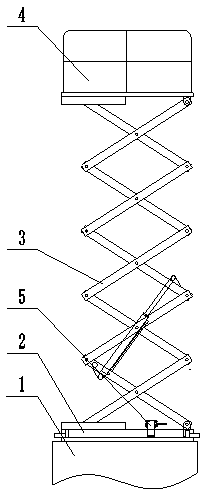

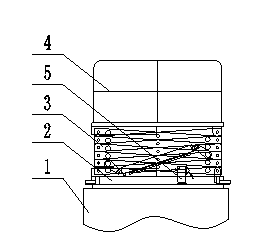

[0016] Such as figure 1 , figure 2 , image 3 As shown, the coal mine fully mechanized mining face hydraulic lifting platform of the present invention includes a scraper conveyor 1, and the scraper conveyor 1 is provided with a traveling mechanism 2 that can move left and right along the scraper conveyor 1, and the traveling mechanism 2 is provided with a movable The lifting mechanism 3 that moves up and down relative to the traveling mechanism 2 is provided with an operating platform 4 on the lifting mechanism 3 .

[0017] One end of the traveling mechanism 2 is provided with a control system 5 for controlling the movement of the traveling mechanism 2 and the lifting mechanism 3 .

[0018] The structure of the walking mechanism 2 is: comprising a hydraulic motor, a gear 9 and a support 6, the hydraulic motor is arranged on the support 6, and the hydraulic motor drives the gear 9 to rotate;

[0019] The gear 9 meshes with the rack provided on the scraper conveyor 1, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com