towel dyeing machine

A technology for dyeing machines and towels, which is applied in the field of towel dyeing machines. It can solve the problems of low liquor ratio and dyeing efficiency, dyeing solution blowing over, and more costs, etc., and achieves convenient replacement, daily maintenance, and cyclic operation. Smooth, reduce the effect of skid chance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further elaborated below through the accompanying drawings and the embodiments of the present invention.

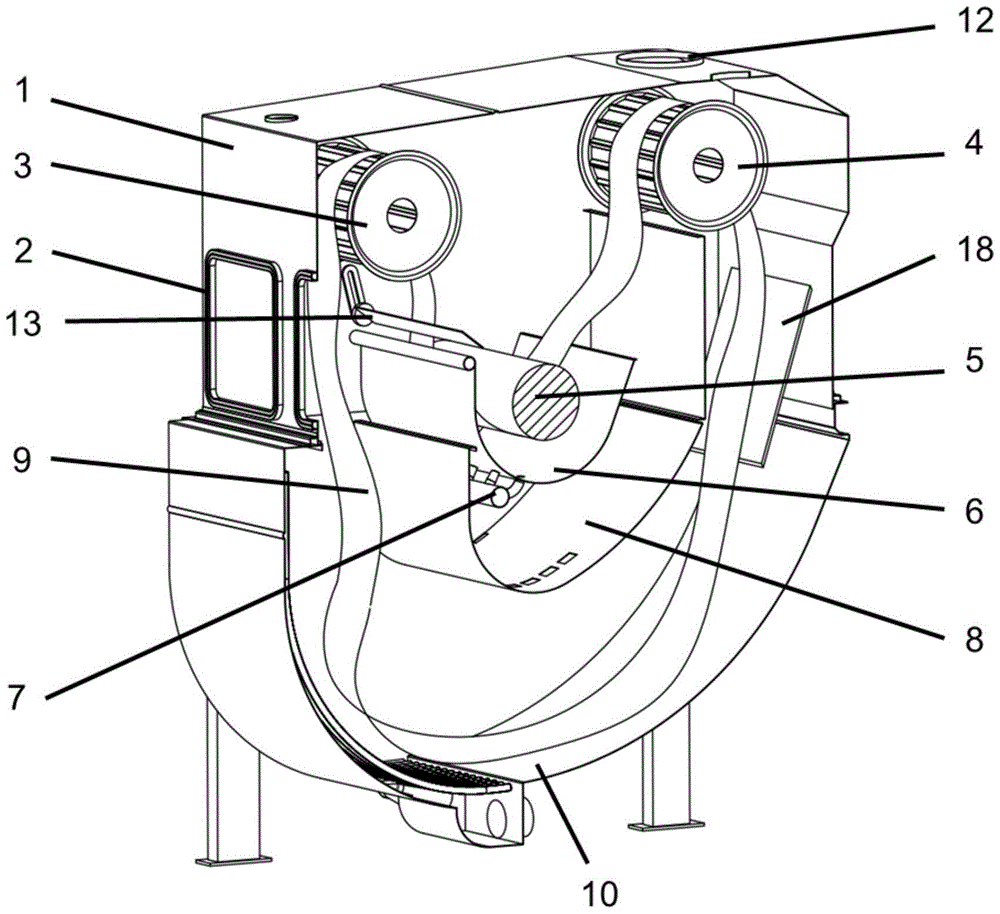

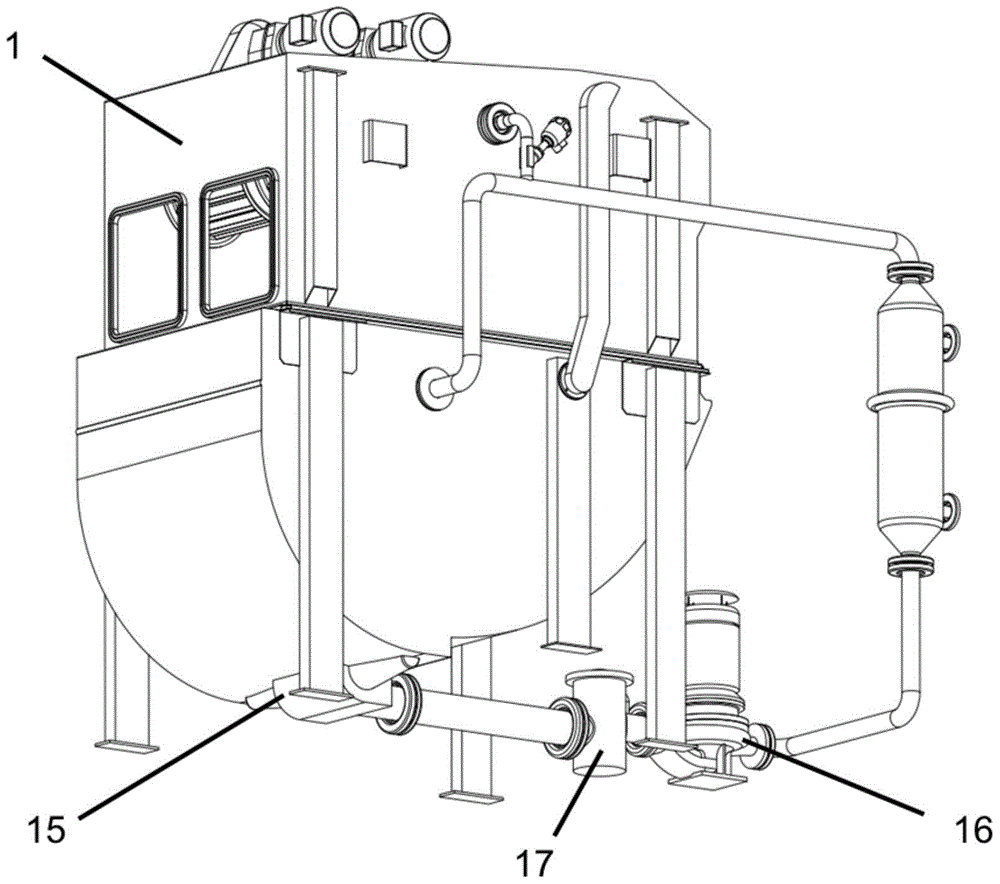

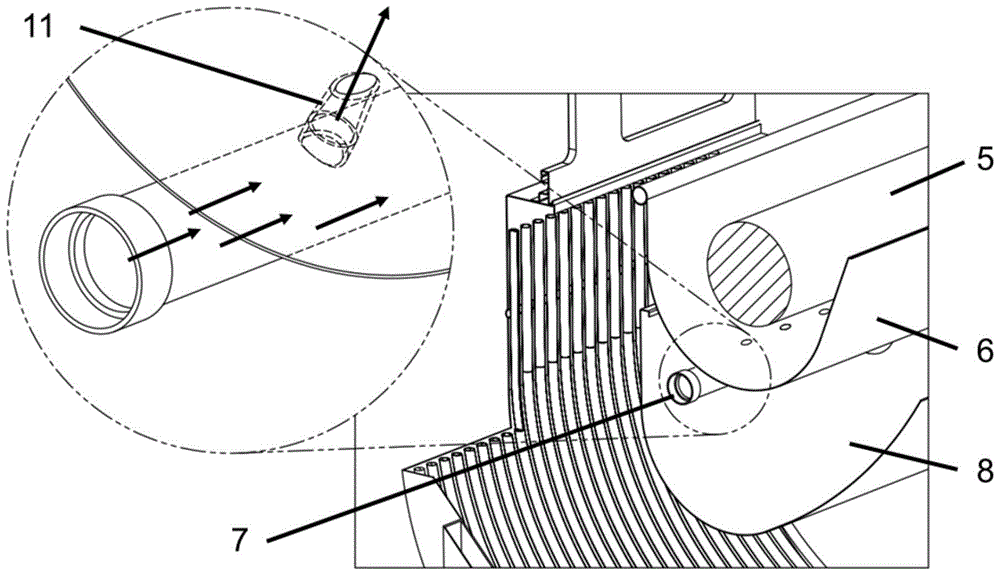

[0052] The structure of the present embodiment towel dyeing machine is as figure 1 is shown in the partial cross-sectional view. This embodiment comprises a main housing 1 of a dyeing machine. There is a working door 2 on the front side of the dyeing machine. There are a lifting drum 3 and an auxiliary lifting drum 4 inside the dyeing machine. There is a dyeing auxiliary tank 6 between the two drums. There is a passive roller 5 inside, and the fabric entering the secondary groove passes through the bottom of the passive roller. A row of nozzle throats 7 is connected to the bottom of the auxiliary tank, and the dye liquor in the dyeing machine is sprayed onto the fabric by spraying. There is also a dividing plate 8 in the dyeing machine to separate the dyeing sub-trough and the dyeing bottom tank 10 at the bottom, so as to prevent clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com