Layering flow tester of low-injection-quantity water injection well

A technology for water injection wells and testers, which can be used in measurement, production of fluids, wellbore/well components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

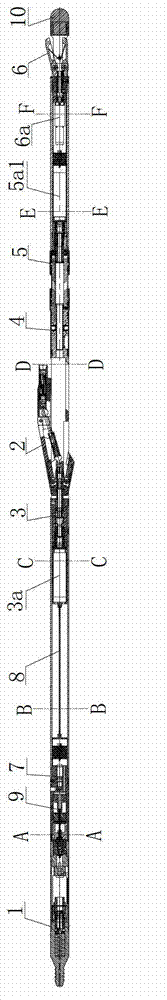

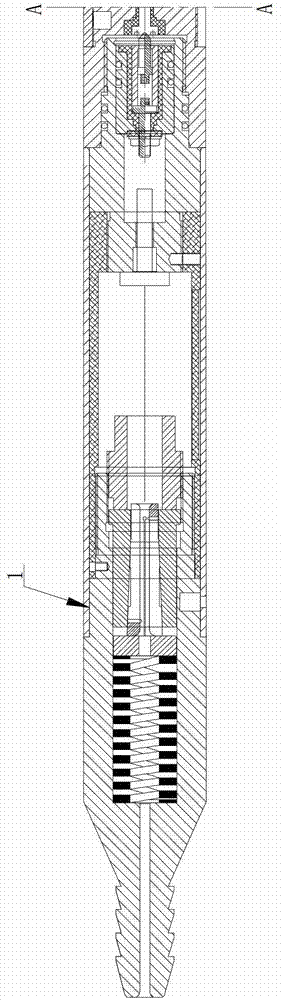

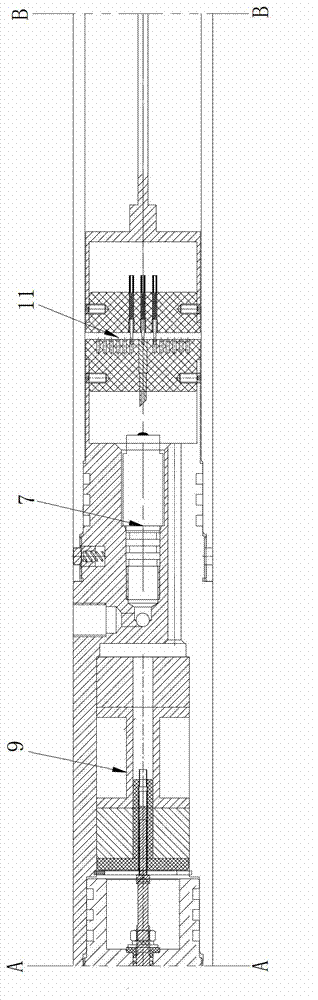

[0033] like Figures 1 to 8BAs shown, the embodiment of the present invention proposes a low injection volume injection well stratified flow tester, which includes a cable head 1, an adjustment arm device 2, an adjustment arm adjustment mechanism 3, an electromagnetic flowmeter assembly 4, a sealing mechanism 5 and Guide mechanism6. The lower end of the cable head 1 is sequentially connected with a pressure temperature sensor 7 and a control module 8 . The adjusting arm device 2 includes an adjusting arm fixing base 2a and an adjusting arm 2b connected to the adjusting arm fixing base 2a. The regulating arm regulating mechanism 3 is connected above the regulating arm device 2 and located below the control module 8, and the regulating arm regulating mechanism 3 controls the opening and closing of the regulating arm 2b. The electromagnetic flowmeter assembly 4 is connected below the adjusting arm device 2, and the electromagnetic flowmeter assembly 4 includes a flow main body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com