Pressure contact type spring pressure test device

A technology of spring pressure and testing device, applied in the direction of measuring device, measuring force, instrument, etc., can solve problems such as interference phenomenon, achieve accurate test results, improve work efficiency, and easy to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

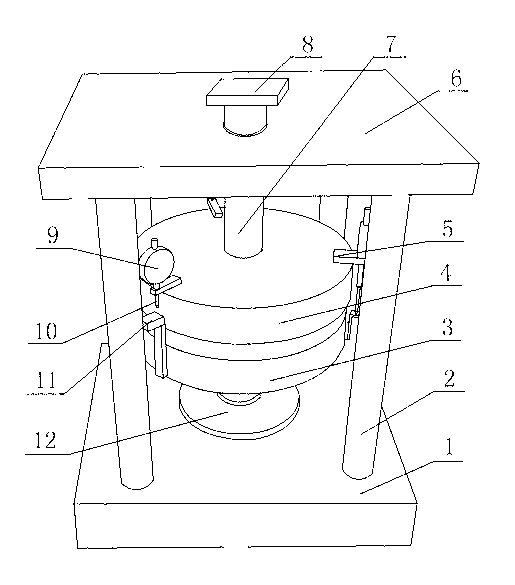

[0020] Such as figure 1 As shown, a spring pressure testing device adopting a pressure contact type includes a base 1, a top plate 6 is arranged on the base 1, a pressure plate is arranged between the top plate 6 and the base 1, one end of the pressure plate is connected with the base 1, and the other end is passed through It passes through the top plate 6 and is arranged outside the top plate 6 , and a contact block 8 is fixed on the end surface. The contact block 8 is a component that is in contact with the pressure structure. The contact block is pressed tightly, and then the pressure plate is driven to press down, and the spring is pressed tightly, and the value is tested.

[0021] Several support columns 2 are arranged between the top plate 6 and the base 1, and the two ends of the support columns 2 are respectively connected with the top plate 6 and the base 1, and the support columns 2 surround the pressure plate. The supporting column 2 and the top plate 6 are positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com