Lens mirror frame and lens assembly

A lens and frame technology, applied in installation, instruments, optics, etc., can solve problems such as easy to cause eccentricity, and achieve the effect of good balance and high-precision fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The lens frame and lens assembly according to the embodiment of the present invention will be described.

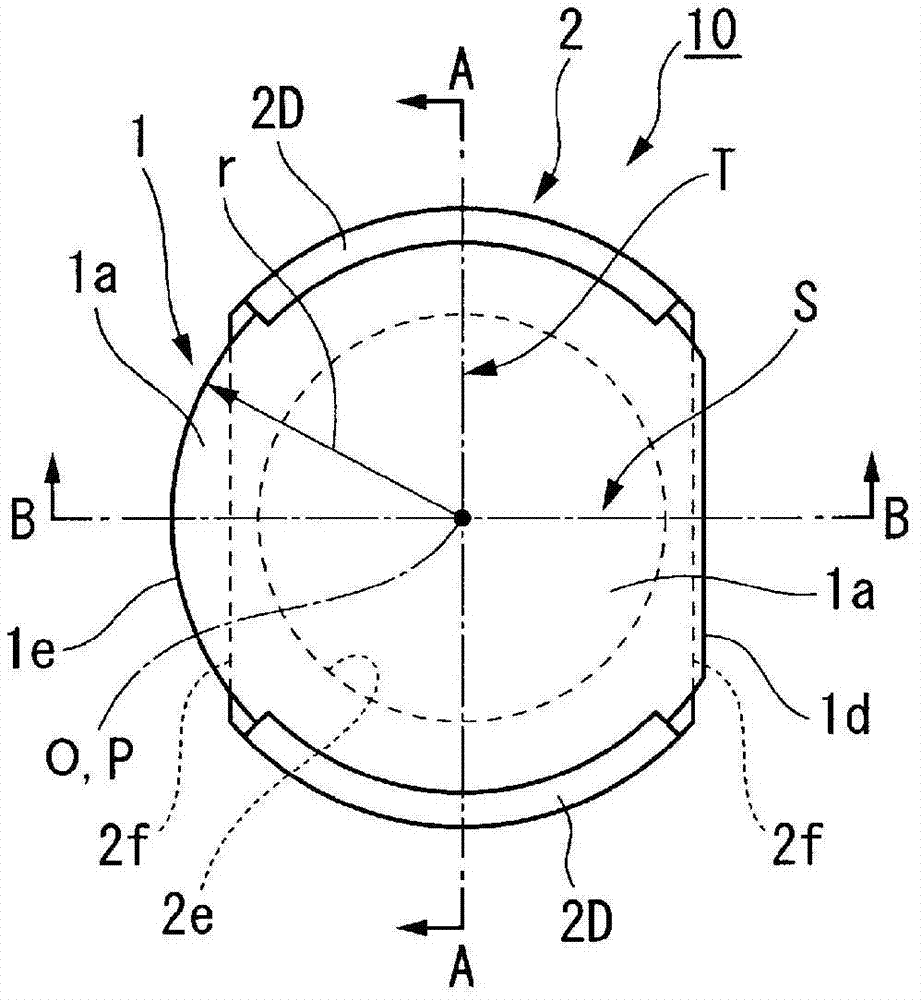

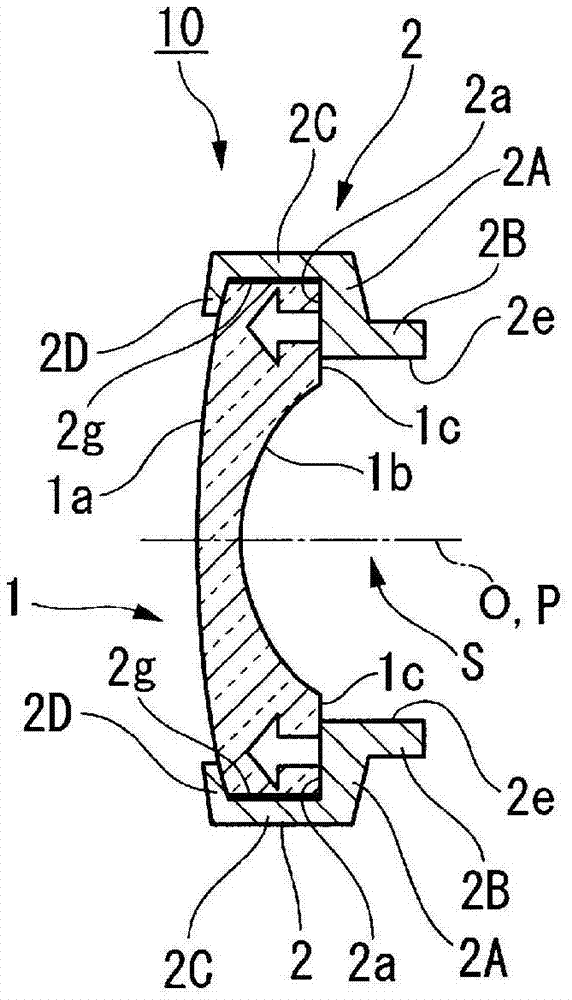

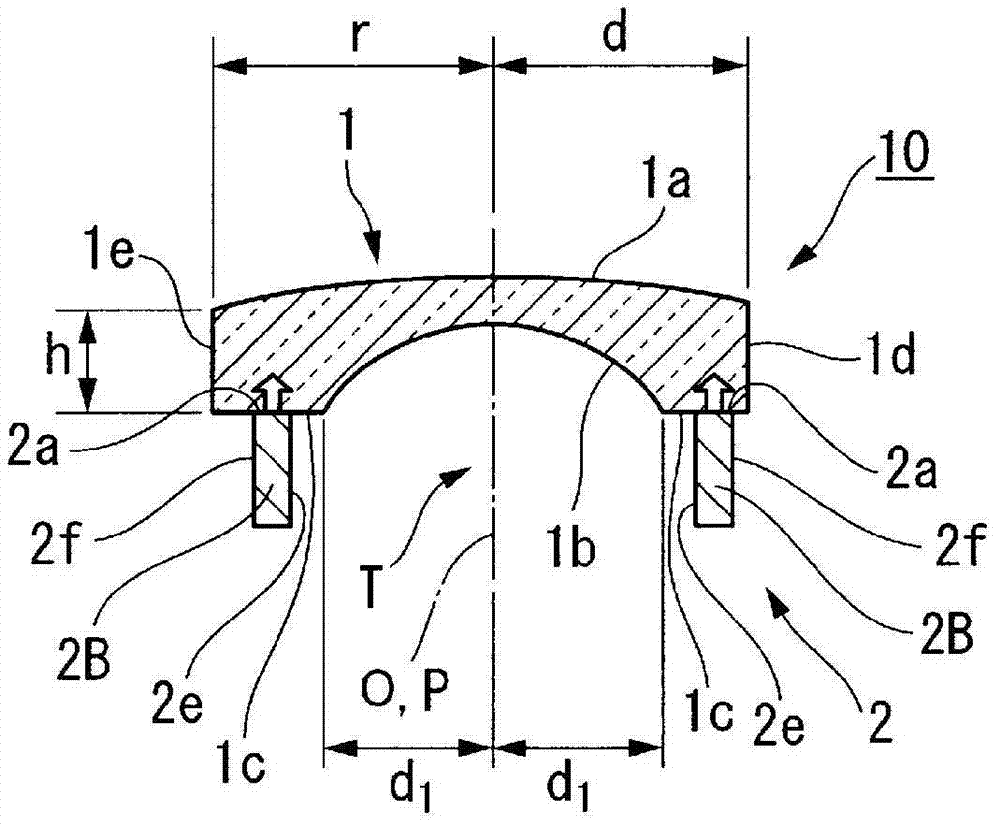

[0065] Figure 1A It is a schematic plan view showing the structure of the lens assembly according to the embodiment of the present invention. Figure 1B , Figure 1C respectively Figure 1A A-A sectional view, B-B sectional view in the. Figure 2A It is a schematic plan view which shows the structure of the lens frame which concerns on embodiment of this invention. Figure 2B , Figure 2C respectively Figure 2A A'-A' section view, B'-B' section view in the.

[0066] Such as Figure 1A , Figure 1B , Figure 1C As shown, the lens assembly 10 of this embodiment is an assembly formed by heat caulking the lens 1 in the thickness direction on the outer edge of the lens 1 and fixing it to the lens frame 2. The lens 1 The outer shape viewed from the direction along the optical axis is formed of a circular arc shape and a straight line shape. The caulking fixi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com