Strong power rapid stirrer

A mixer, fast technology, applied in the field of mixing machinery, can solve the problems of uneven mixing of materials, unsmooth discharge, long mixing time, etc., and achieve the effect of high output efficiency, high production capacity, and various mixing forms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can understand.

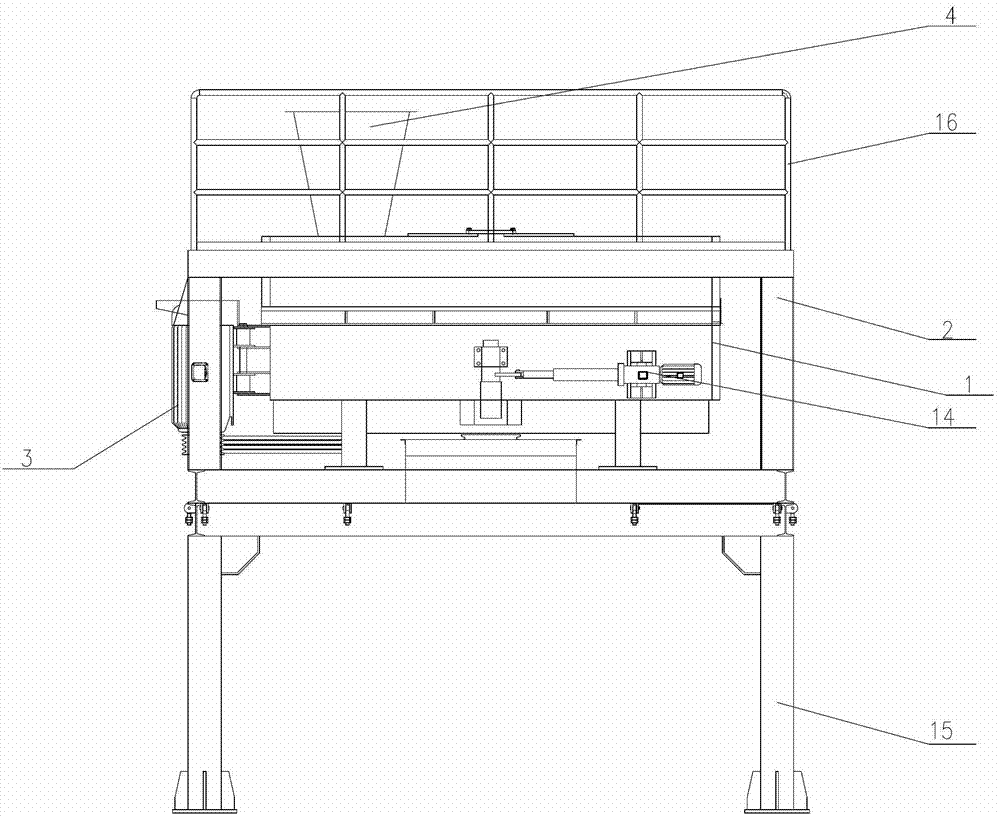

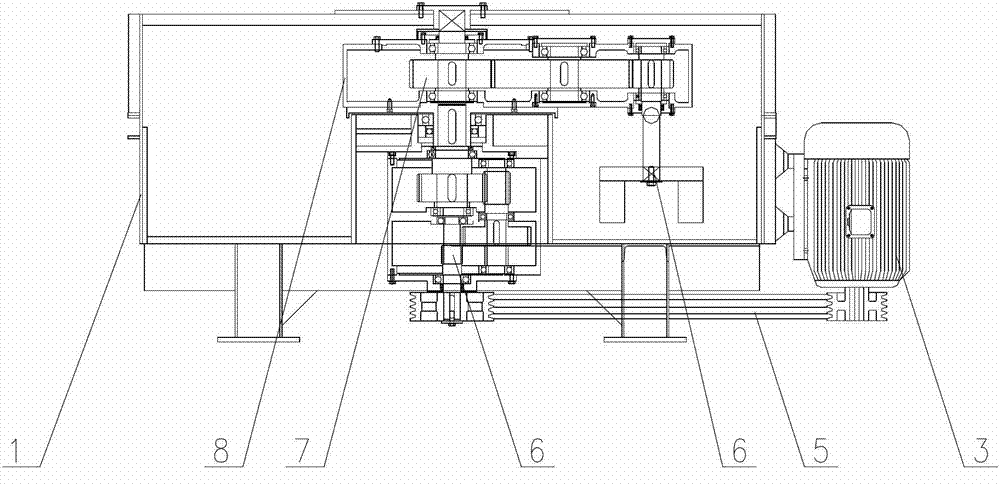

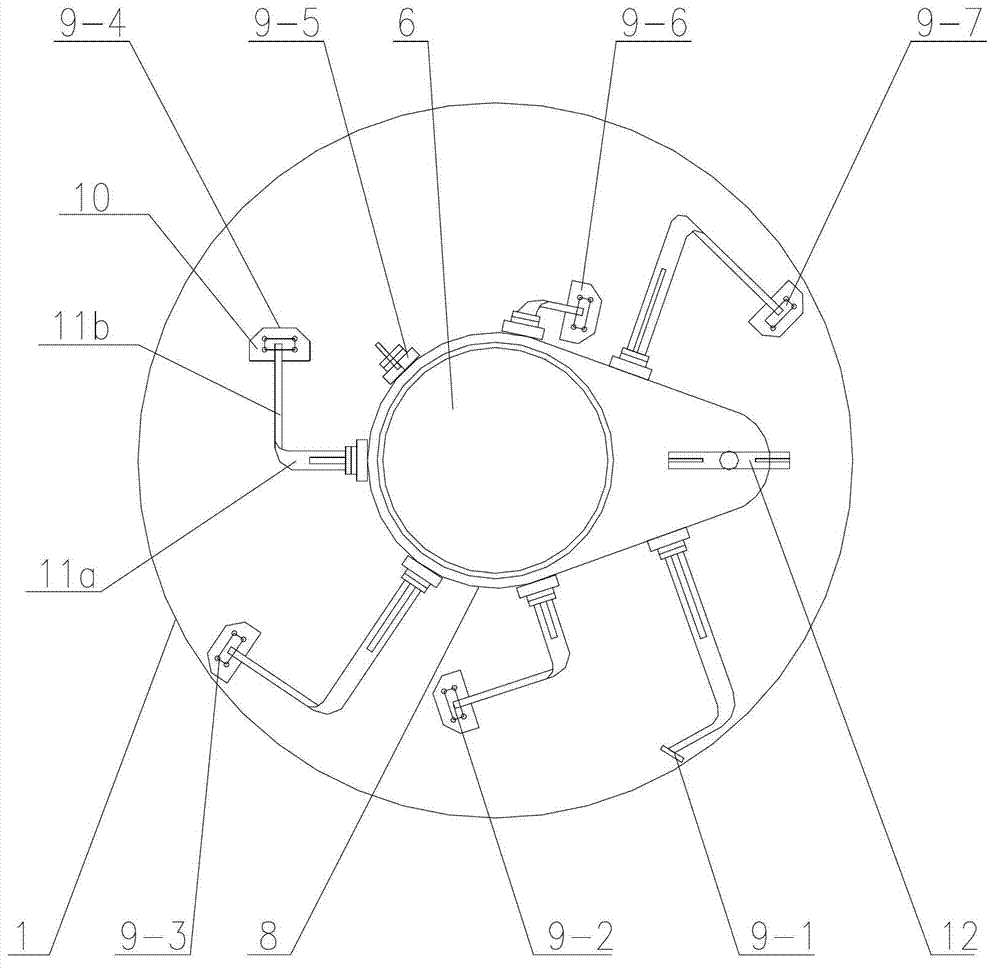

[0026] A powerful fast mixer is shown in the figure, which includes a cylinder body 1, a cylinder body frame 2, a bracket 15, a top railing 16, a motor 3 is arranged on the outer wall of the cylinder body 1, a feed hopper 4 is arranged under the cylinder body 1, and a motor 3 The main reducer 6 installed in the barrel 1 is connected through the belt 5, the upper end of the main reducer 6 is provided with a secondary reducer 7, and the periphery of the secondary reducer 7 is provided with a rotating body 8, and the upper edge of the outer wall of the rotating body 8 The axis direction is staggered with a scraper 9, and a planetary stirring device 12 is installed under the secondary reducer 7. The bottom of the cylinder 1 is provided with a discharge port door 13, and an electro-hydraulic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com