Dye stirring device for rotary screen printing machine

A technology of rotary screen printing and stirring device, which is applied in the directions of mixer, transportation and packaging, dissolving, etc., can solve the problems of poor stirring effect, single stirring form, and slow stirring of dyestuffs evenly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

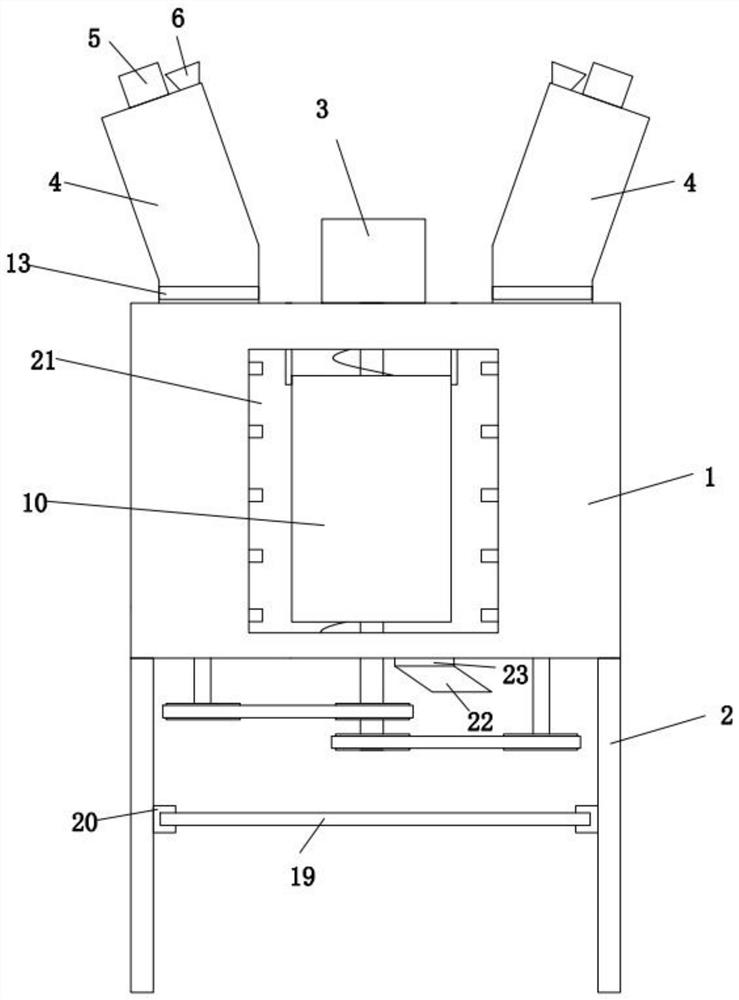

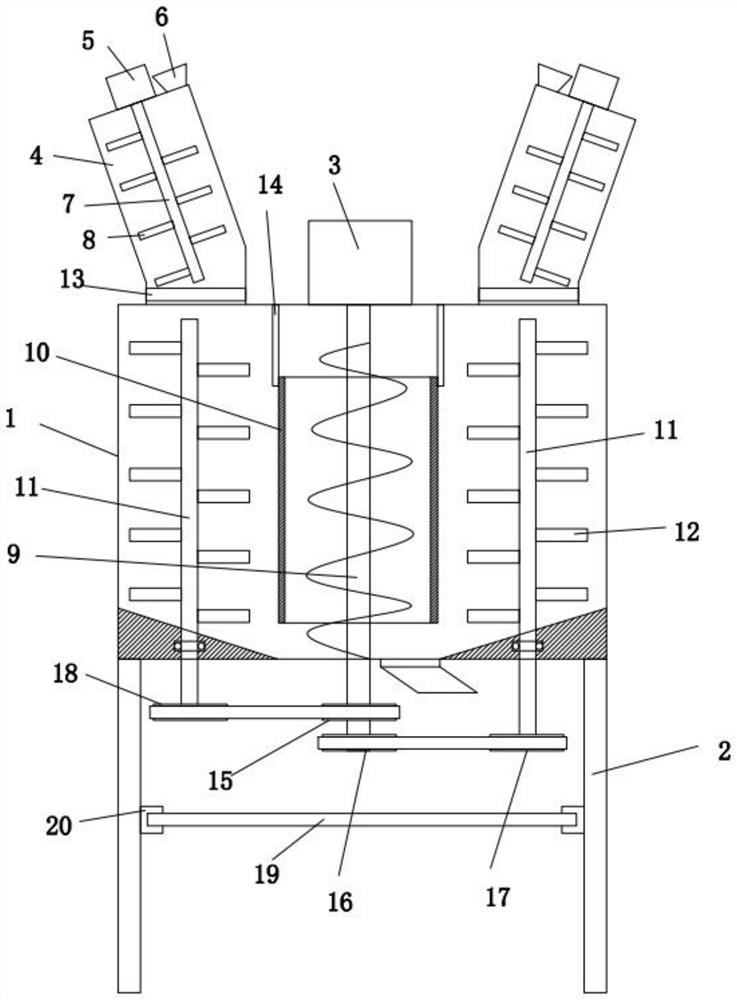

[0016] A dye stirring device for a rotary screen printing machine, comprising a barrel body 1, the lower end of the barrel body 1 is provided with a leg 2, the upper end of the barrel body 1 is provided with a motor one 3 and a stirring machine located on both sides of the motor one 3 barrel 4, the upper end of the mixing barrel 4 is provided with a motor two 5 and a feed port 6, the stirring barrel 4 is provided with a stirring shaft one 7 connected with the motor two 5, and the stirring shaft one 7 is provided with a stirring blade - 8, a solenoid valve 13 is provided at the connection between the lower end of the mixing tank 4 and the barrel body 1, the barrel body 1 is provided with an outer cover 10 and a screw conveying shaft 9 connected to the motor one 3 and located in the outer cover 10, Both sides of the outer cover 10 in the barrel body 1 are provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com