Large-tonnage wood clamping machine

A log-carrying, large-tonnage technology, which is applied to earth movers/shovels, mechanically driven excavators/dredgers, construction, etc., can solve the problems of large lateral torque and torsion cracking, and achieve lateral torque resistance Strong torque capacity, improved ability to resist lateral torque, and good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

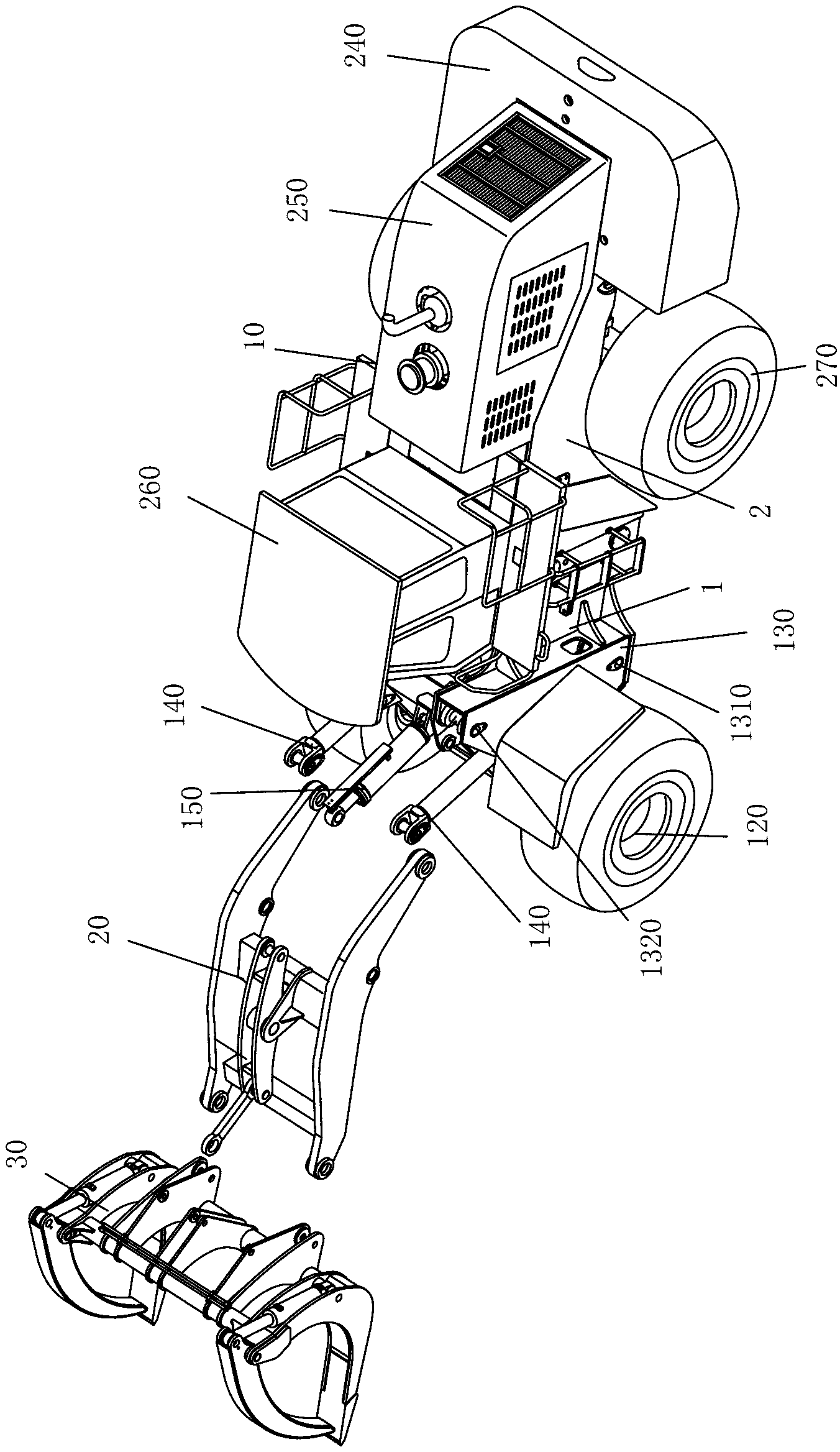

[0029] Please refer to figure 1 and figure 2 . This large-tonnage wood clamping vehicle has these three parts of main machine 10, boom assembly 20 and wood clamping device 30.

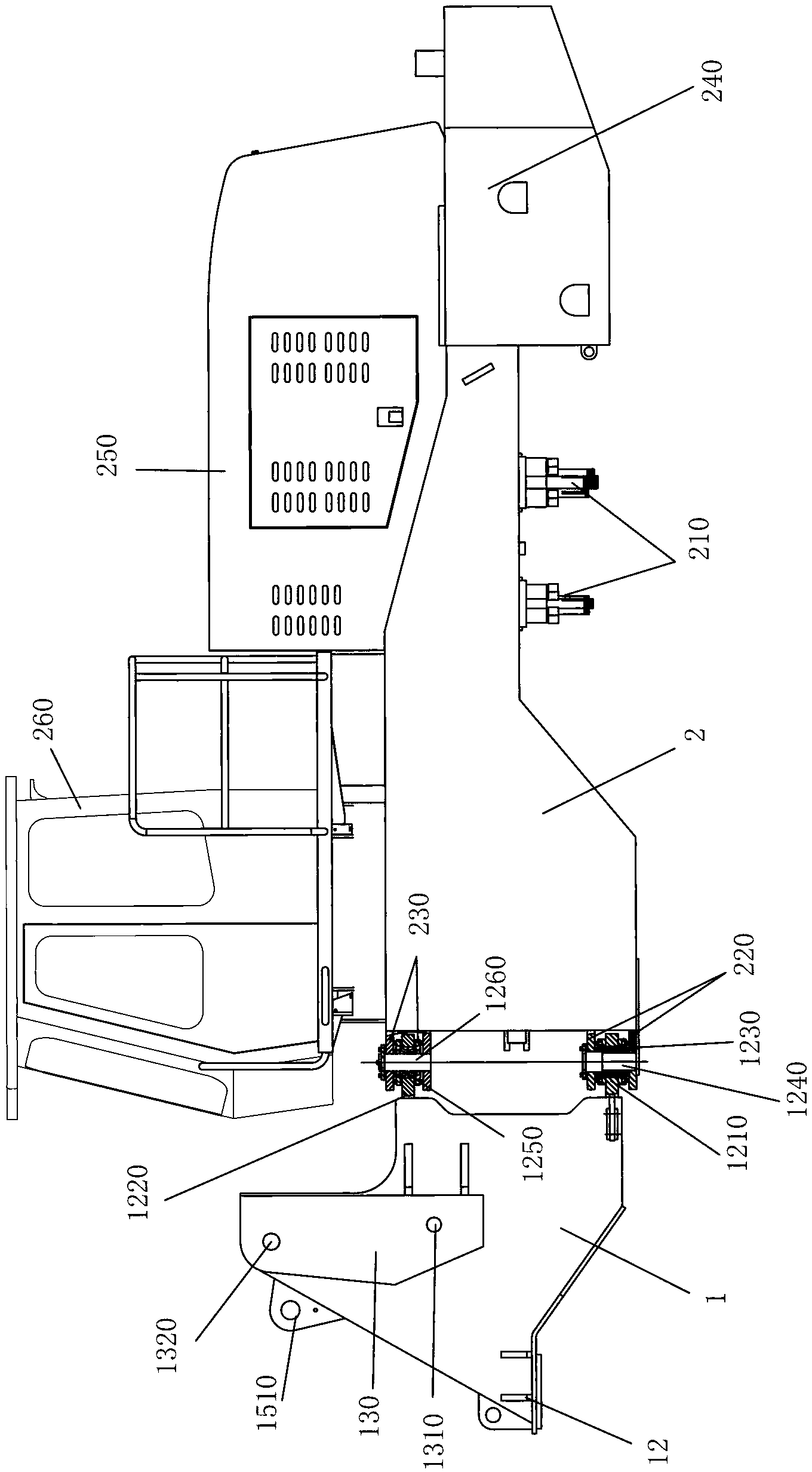

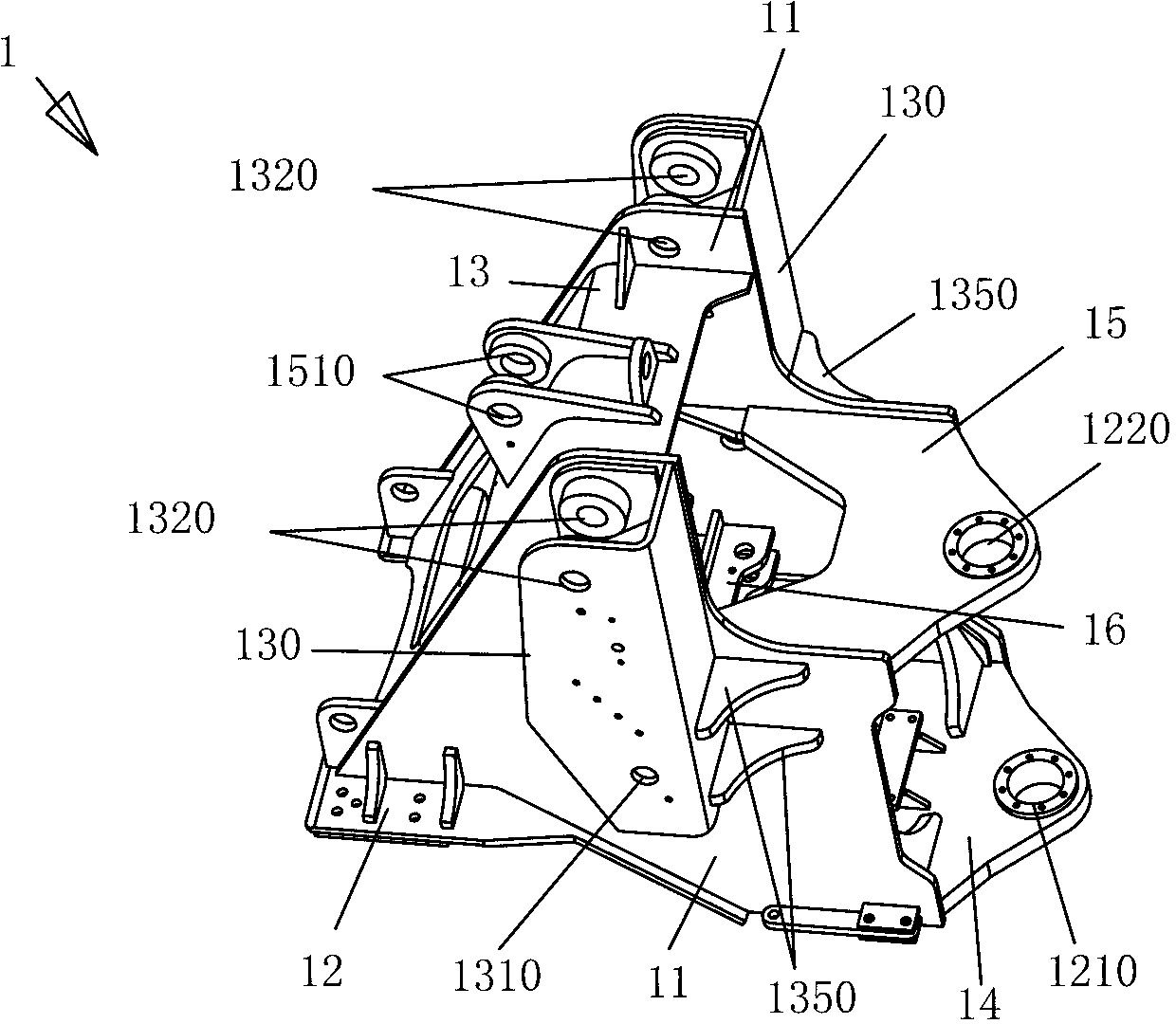

[0030] The front vehicle frame 1 rear portion of main engine 10 establishes lower hinged seat 1210 and upper hinged seat 1220, butt joint lower hinged seat 220 and upper hinged seat 230 of rear vehicle frame 2 front ends tiger head respectively. The hinged span between the lower hinged seat 1210 and the upper hinged seat 1220 of the front frame 1 is 0.9-1.6 meters. A pair of oppositely arranged tapered roller bearings 1230 are installed on the lower hinged seat 1210 to connect the lower hinged shaft 1240 , and the lower hinged shaft 1240 is hinged with the lower hinged seat 220 of the rear vehicle frame 2 . A pair of oppositely arranged tapered roller bearings 1250 are installed on the upper hinge seat 1220 to connect the upper hinge shaft 1260 , and the upper hinge shaft 1260 is hinged with the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com