Method of establishing coking coal ash content influence model on thermal performance of coke

An impact model and coking coal technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the quantitative impact of unreported coke thermal properties, the impact of unreported coke reaction thermal properties, etc. The effect of coal guiding ideology science

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail through specific embodiments below.

[0016] Technical scheme of the present invention comprises the steps:

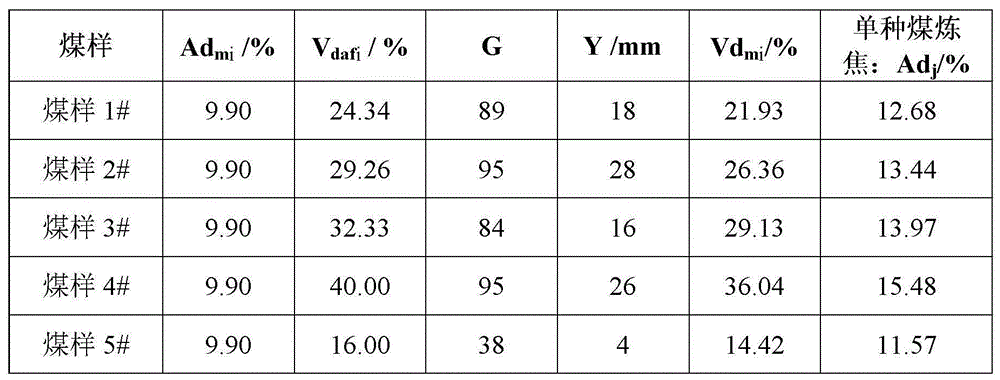

[0017] 1) Set Vd mi = V daf ×(100-Ad mi ) / 100, to calculate the dry basis volatile Vd of the i-th single coking coal in the blended coal mi coal;

[0018] 2) Setting , the w i is the weight ratio on a dry basis of the i-th single coking coal in the blended coal; the volatile matter Vd on a dry basis of each single coking coal in the blended coal calculated in step 1) mi Substituting the numerical value of step 2) into the formula to calculate the dry basis ash content of the coke;

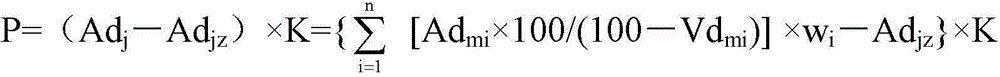

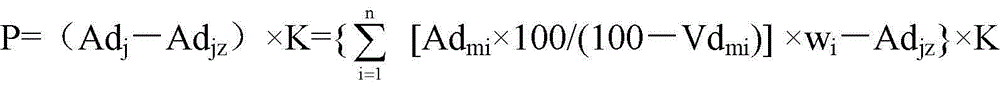

[0019] 3) Set P to be the influence index of the ash content of each single coking coal in the blended coal on the thermal performance of coke, and let:

[0020] P = ( A d j - A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com