Manufacturing method for metamaterial antenna housing

A manufacturing method and technology of radome, applied in the field of radome, can solve the problems that the process cannot be realized, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

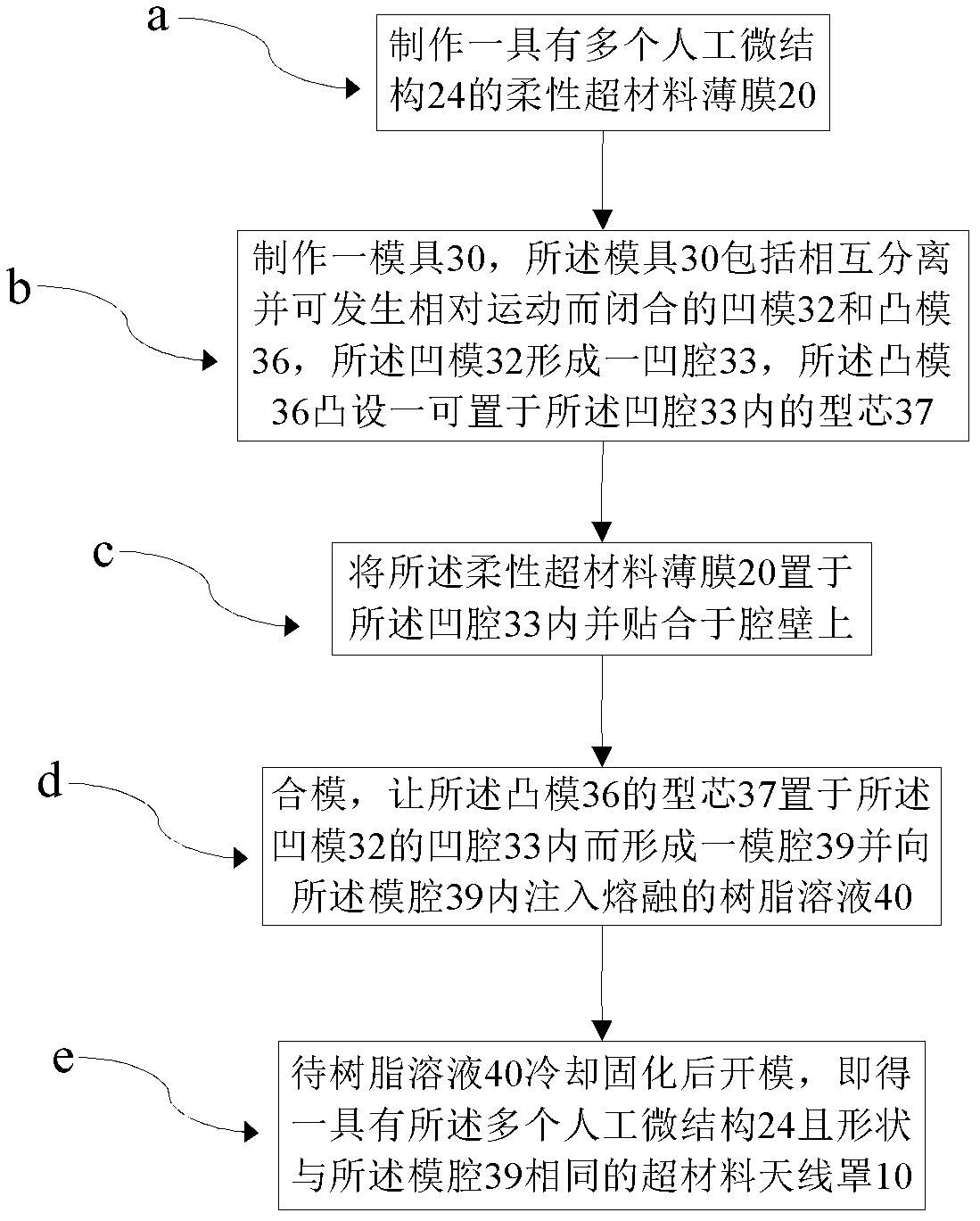

[0031] Such as Figure 1 to Figure 5 Shown is a preferred embodiment of the manufacturing method of the metamaterial radome of the present invention. The preferred embodiment includes the following steps:

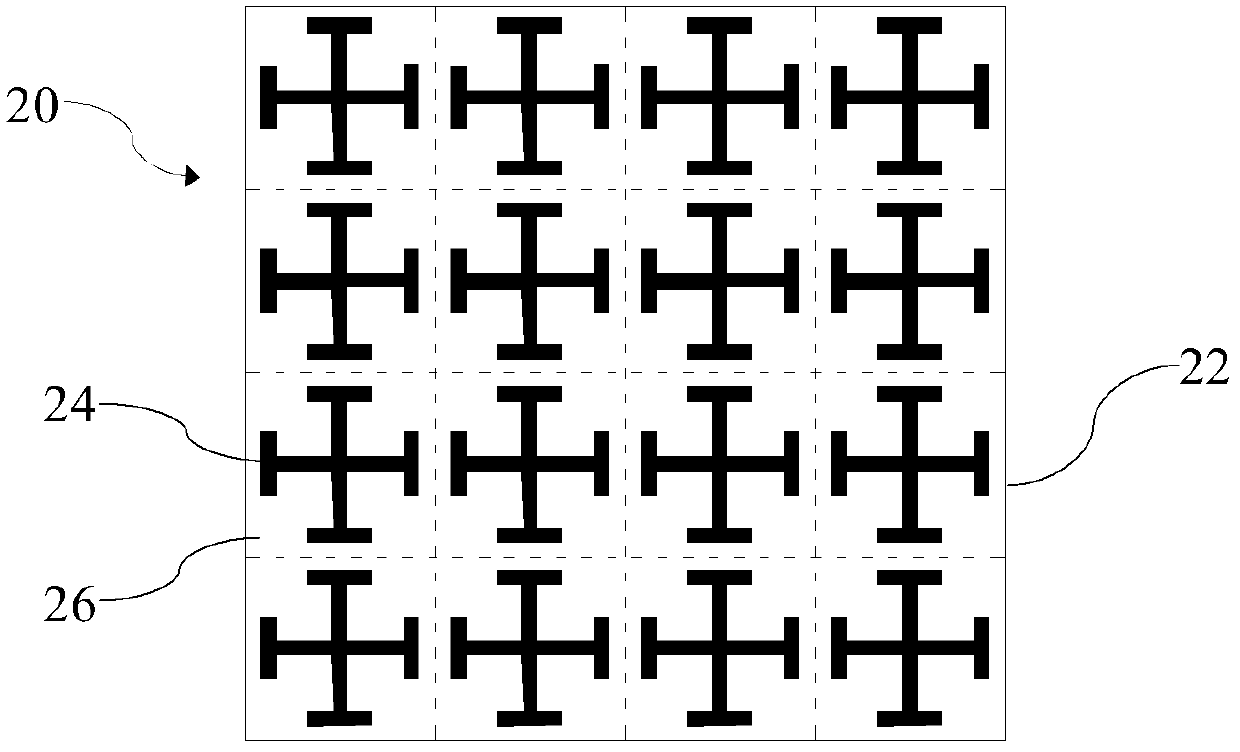

[0032] a. Fabricate a flexible metamaterial film 20 with a plurality of artificial microstructures 24 .

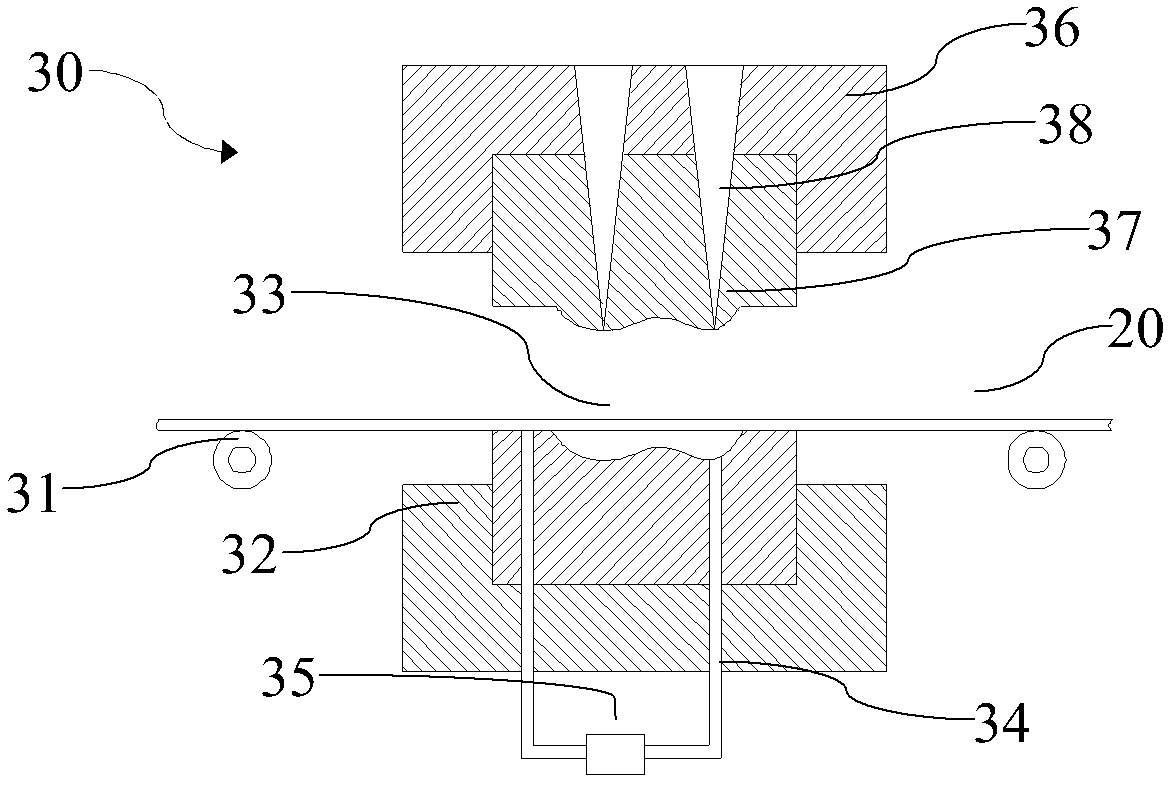

[0033] b. make a mold 30, the mold 30 includes a die 32 and a punch 36 that are separated from each other and can be closed relative to each other, the die 32 forms a cavity 33, and the punch 36 is provided with a A core 37 placed in the cavity 33 .

[0034] c. placing the flexible metamaterial film 20 in the concave cavity 33 and attaching it to the cavity wall.

[0035] d. Mold closing, let the core 37 of the male mold 36 be placed in the concave cavity 33 of the female mold 32 to form a mold cavity 39 and inject the molten resin solution 40 into the mold cavity 39 .

[0036] e. After the resin solution 40 is cooled and solidified, the mold is opened to obtain a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com