Magneto-electric rotation reciprocating device

A reciprocating device, magnetoelectric technology, applied in the direction of electromechanical devices, electrical components, etc., can solve the problems of coil heating, low sensitivity, easy burning and energy consumption, etc., and achieve the effect of fast rotation speed, high sensitivity and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

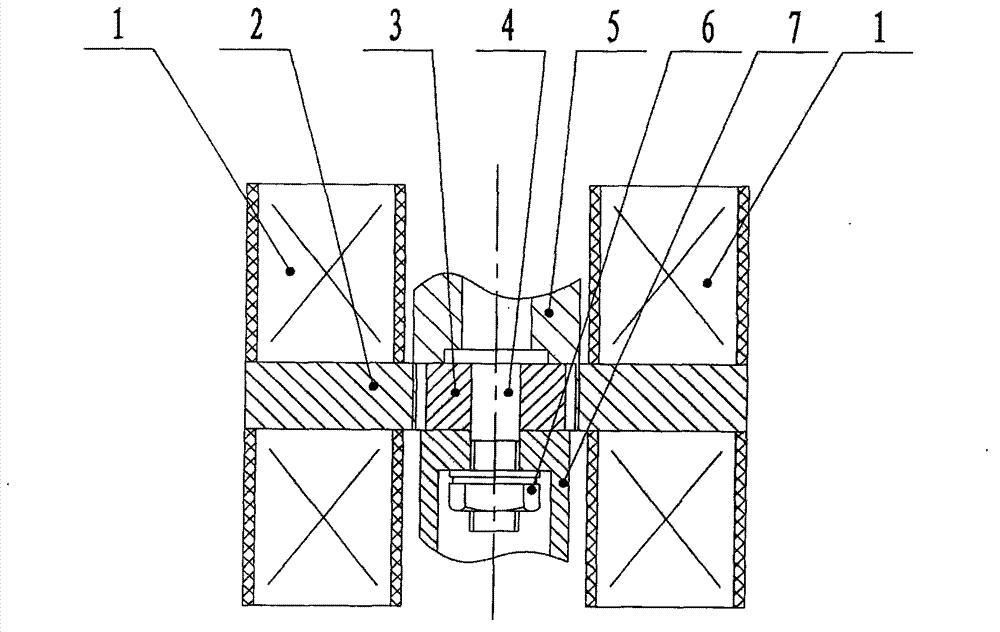

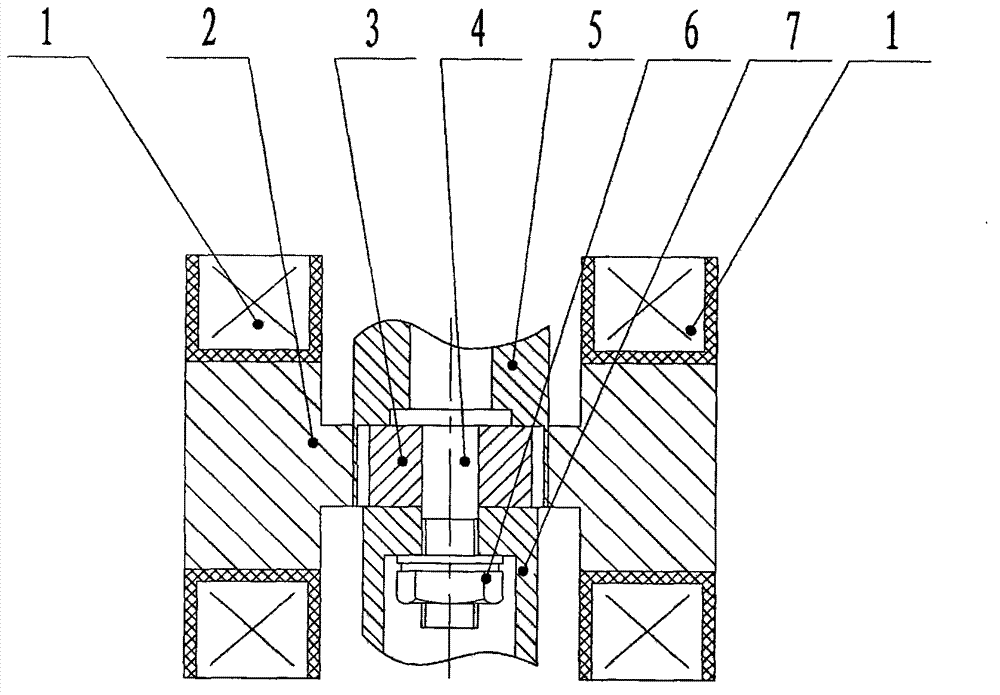

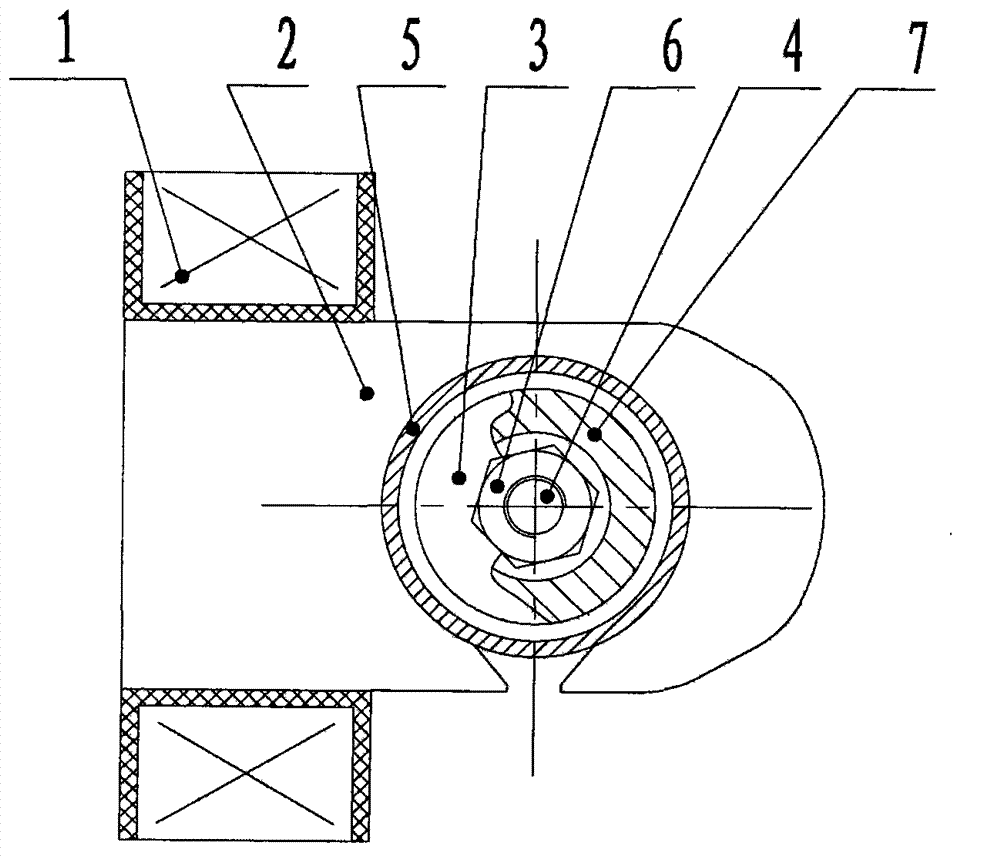

[0026] like figure 1 As shown, it is a schematic structural view of the first embodiment of the electromagnetic rotary reciprocating device in the present invention, the device of this embodiment includes:

[0027] The first component includes an iron core 2 and a coil 1 , and the two ends of the iron core 2 are respectively wound with the coil 1 .

[0028] The second component includes a permanent magnet 3 and a connecting rod group 4, the permanent magnet 3 runs through the iron core 2, and the permanent magnet 3 is connected with the connecting rod group 4;

[0029] When a forward or reverse pulse current is passed through the coil, an attractive or repulsive fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com