Energy-saving production method of functional edible oil

A production method and technology for edible oil, applied in the production and application of edible oil/fat, fatty acid, etc., can solve problems such as unfavorable green environmental protection, increase production cost, increase energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

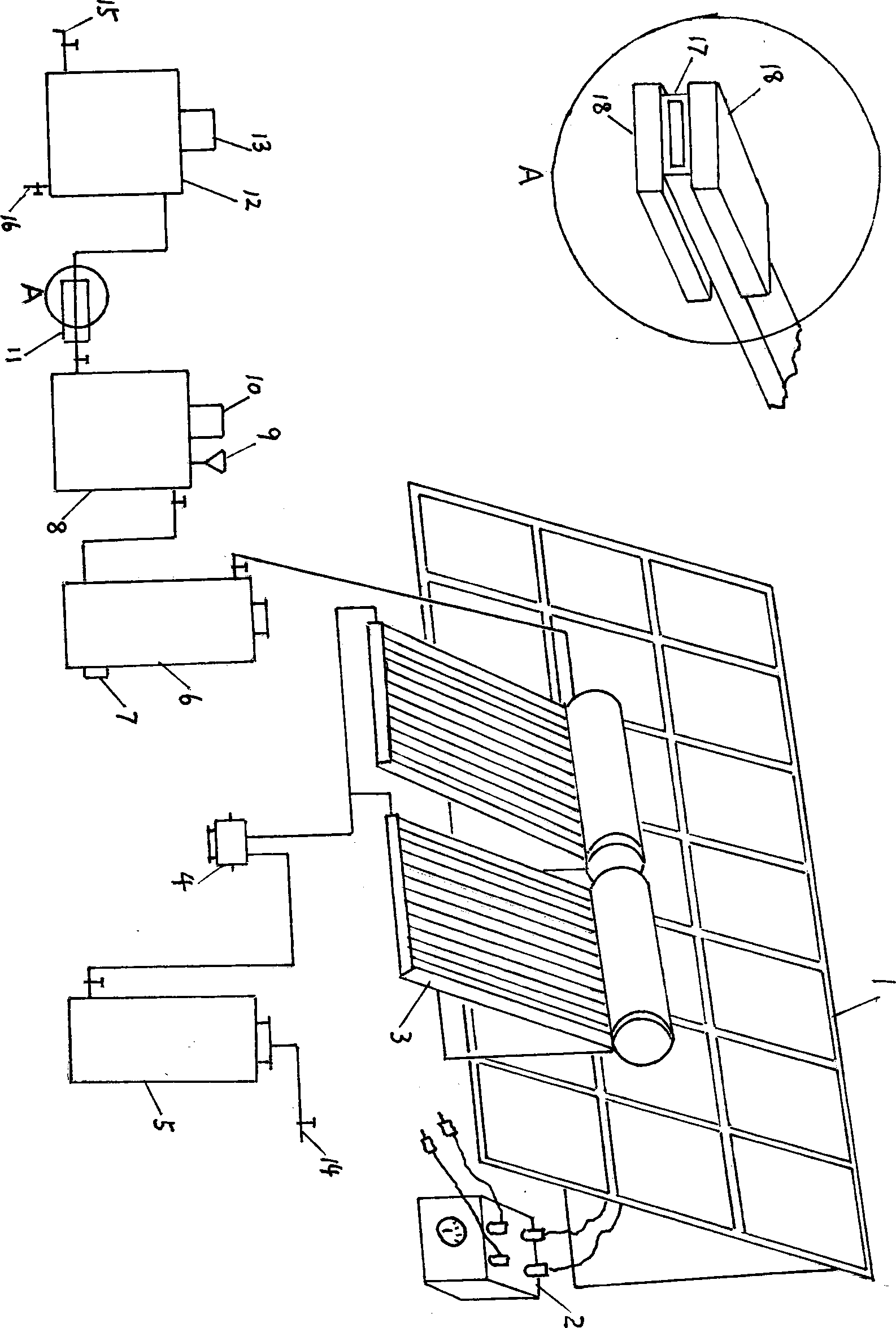

[0009] Reference in the examples of the present invention figure 1 The energy-saving production method of a functional edible oil, the functional edible oil formula combination one, mainly adopts 50-58% of canola oil (corolla oil), supplemented by 35-40% of corn oil, and adds trace amount of lycopene 1.5-2.5%, vitamin E 0.01-0.03% and astaxanthin 1.5-3%, the main production process is in the fully enclosed automatic system of the aseptic workshop, and the mixed vegetable edible oil without any preservatives enters through the oil inlet 14 The raw material oil storage tank 5 is heated to 40-60 degrees in the solar heater 3 through the oil pump 4 and the stainless steel piping system, and enters the thermal oil tank 6 for heat preservation, and the automatic temperature controller and the electric auxiliary heater 7 installed in the tank are automatically adjusted The pre-set edible oil temperature in the tank reaches the temperature value required by the process. The electric a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com