Wooden member assembly

A component assembly and component technology, which is applied in the field of wooden component assemblies, can solve the problems of joint obstruction, enlarged reinforced steel rod structure, and enlarged contact area of metal parts, etc., and achieves the effect of easy joint, change of appearance, and good appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Hereinafter, embodiments of the present invention will be described based on the drawings.

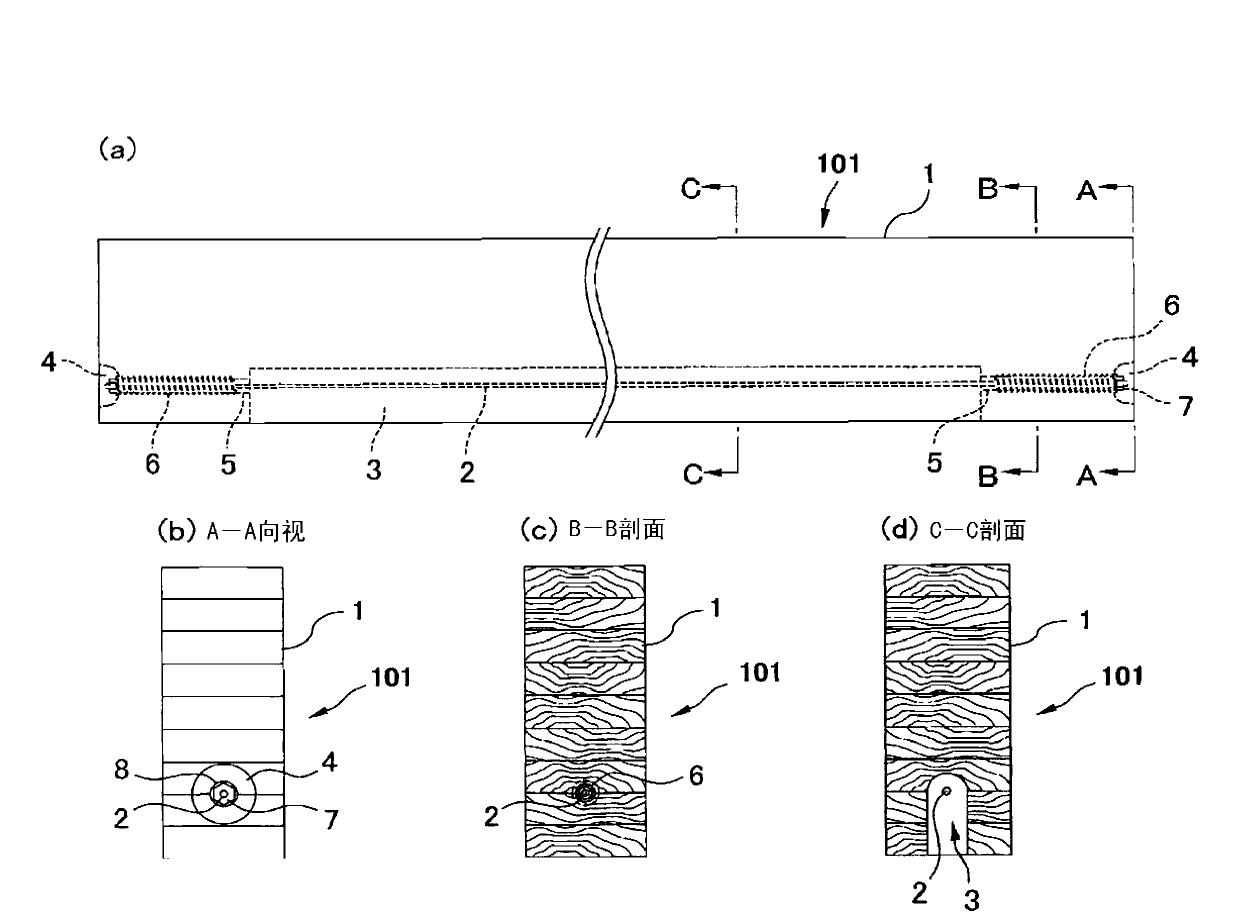

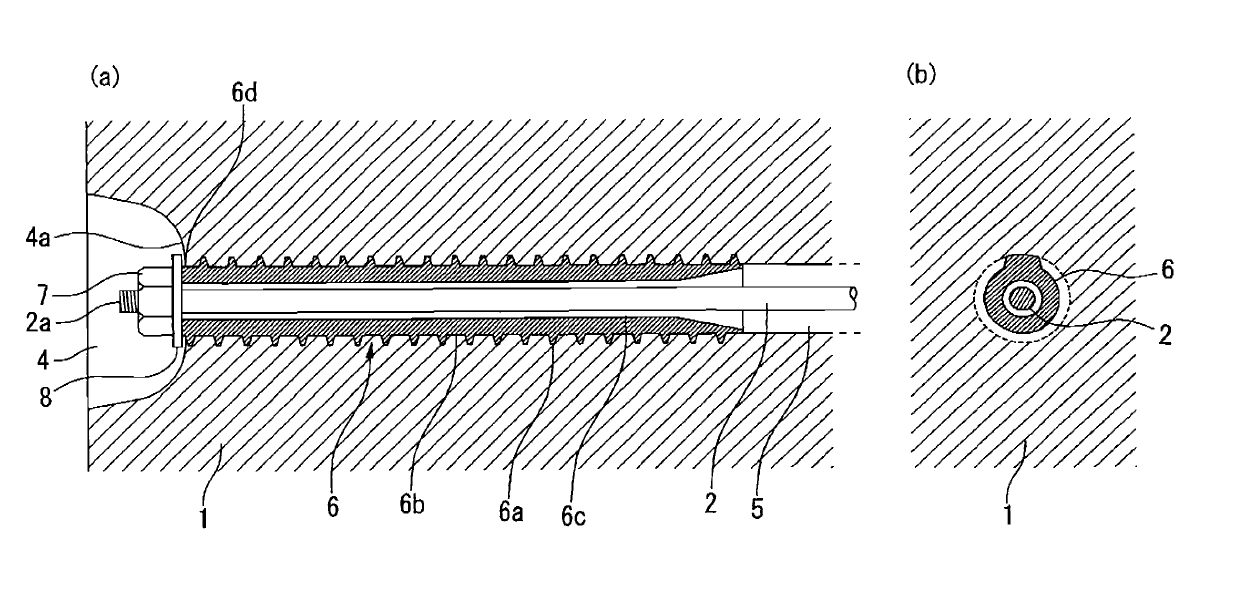

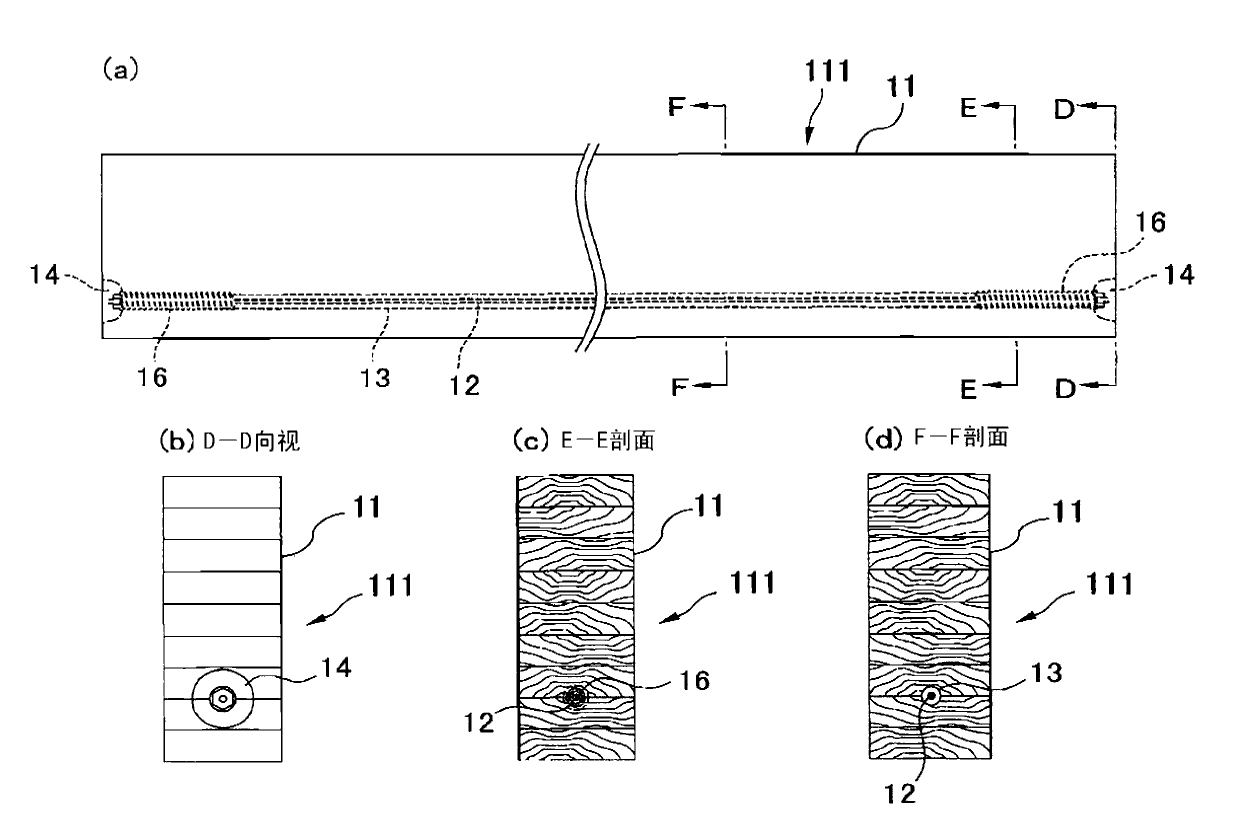

[0034] figure 1 It is a schematic side view showing a wooden member as an embodiment of the present invention, a view taken along the line AA shown in the side view, a BB sectional view, and a CC sectional view. also, figure 2 It is a vertical cross-sectional view and a horizontal cross-sectional view showing a portion into which a screw member is screwed.

[0035] The wood component assembly 101 is as figure 1 As shown, a wooden member 1, a steel rod 2 as a tension member, and a screw member 6 are provided. That is, the steel rod 2 whose both ends are fixed to the screw member 6 is arranged in the axial direction of the wooden member 1, and the tension force of the steel rod 2 introduces prestress.

[0036] The above-mentioned wooden part 1 is formed by laminating a plurality of glulams with a small cross-section made of a plate-shaped wooden material. In this embodiment, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com