Cotton spinning combing machine draft adjustment device

An adjustment device and combing machine technology, which is applied in the direction of combing machines, textiles and papermaking, fiber processing, etc., can solve the problems of parallel and accurate values, the roller gauge cannot be fine-tuned quickly, and the rollers cannot be adjusted to achieve excellent performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

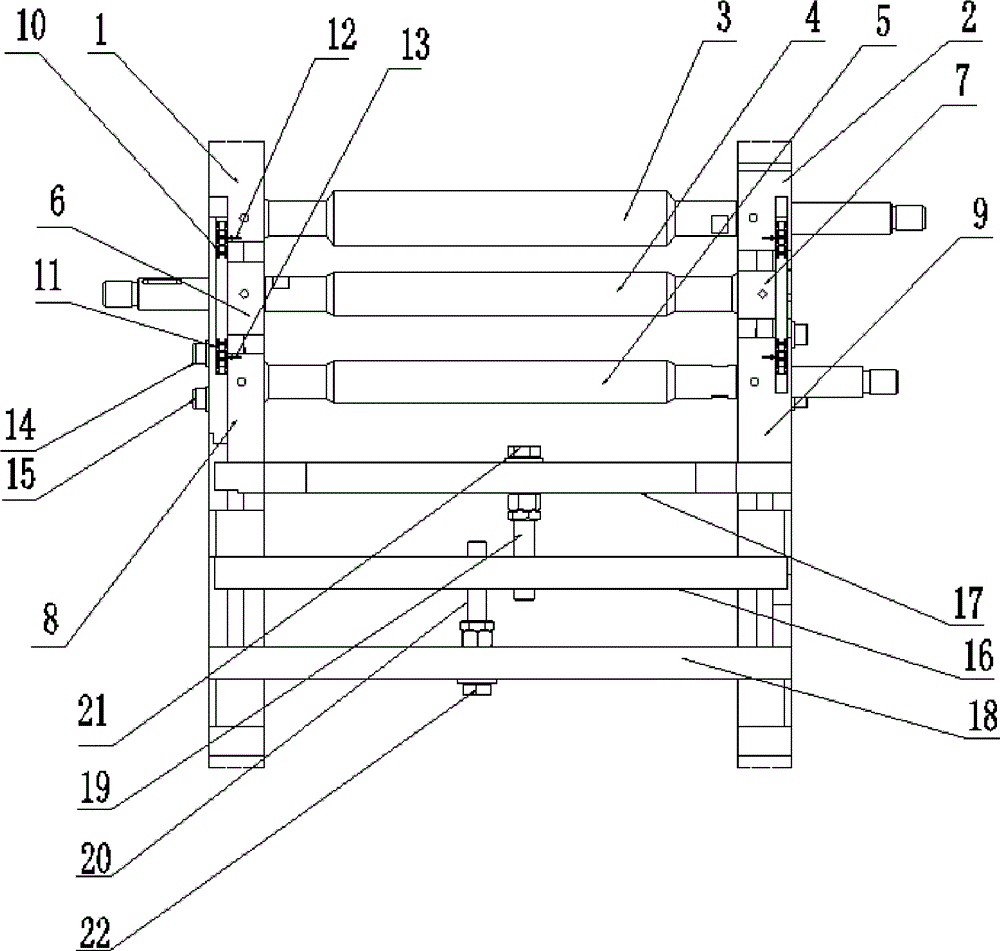

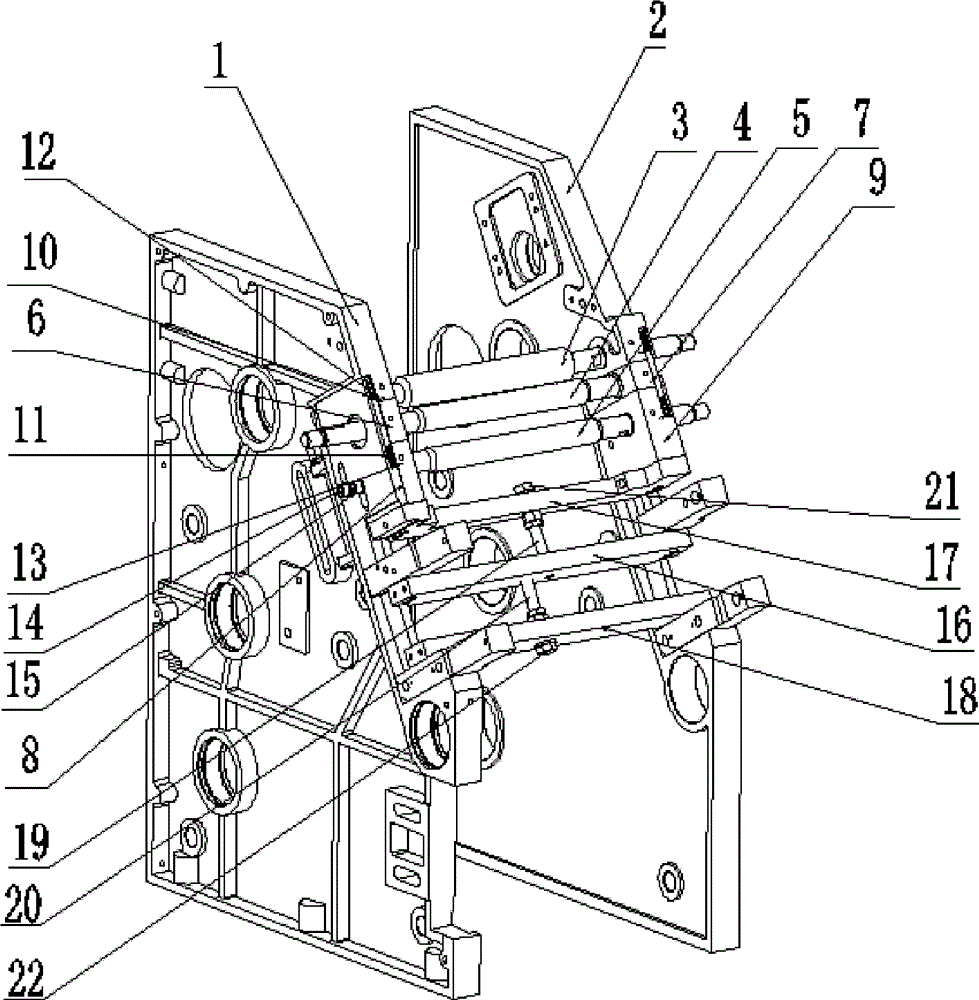

[0011] Embodiment: A draft adjustment device for cotton combing machine, comprising left wallboard 1, right wallboard 2, front roller 3, middle roller 4, rear roller 5, left middle roller seat 6, right middle roller seat 7, left The rear roller seat 8 and the right rear roller seat 9, the left and right wallboards 1 and 2 are arranged in parallel and at intervals, the axial ends of the front roller 3 are respectively fixed on the left and right wallboards 1 and 2, and the middle rollers are 4 shafts The two ends are respectively fixed on the left and right middle roller seats 6 and 7, the axial ends of the rear roller 5 are respectively fixed on the left and right rear roller seats 8 and 9, and the left and right middle roller seats 6 and 7 are respectively Embedded on the left and right wallboards 1, 2, the left and right middle roller seats 6, 7 can slide along the vertical direction of the axes of the front roller 3 and middle roller 4, and the left and right rear roller sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com