Missile rain-proof cover device

A technology of mouth cover and missile, which is applied in the direction of self-propelled bombs, projectiles, offensive equipment, etc. It can solve the problems of large occupied volume, inability to arrange, and inability to meet the strength limit of spring materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

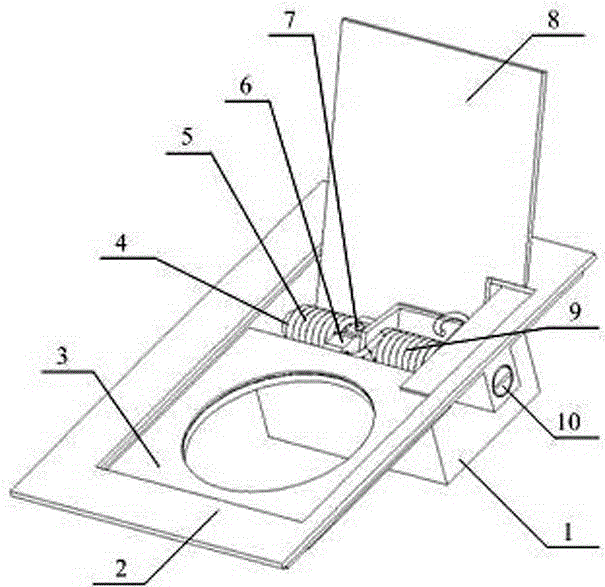

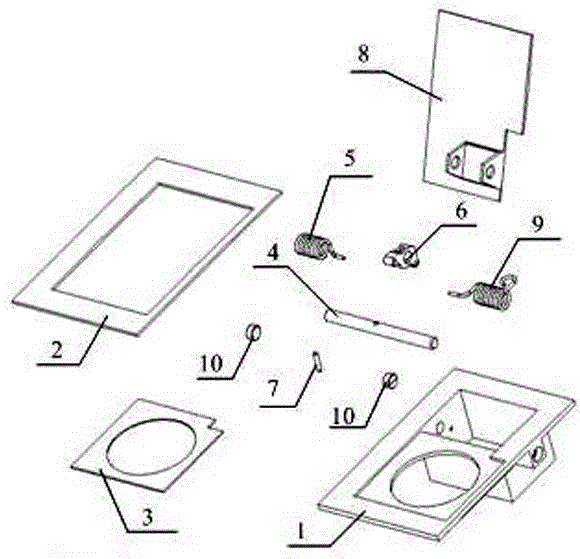

[0018] Attached below figure 1 , 2 The present invention is described in detail:

[0019] A missile rainproof cover device, which includes a cover 8, a base 1, an outer skin 2, an elastic deformation plate 3, a torsion spring I5, a torsion spring II9, a block 6 connecting the torsion spring, a rotating shaft 4, and a lock Tighten the pin 7, the above-mentioned torsion spring I5, torsion spring II9, block 6 and mouth cover 8 are fixed on the base 1 through the rotating shaft 4;

[0020] The other end of the torsion spring I5 and one end of the torsion spring II9 are fixed on the block 6, and the other end of the torsion spring II9 is fixed on the cover 8 as the driving force for the rotation of the cover 8;

[0021] The locking pin 7 connects the clamping block 6 with the rotating shaft 4, and locks the nut 10 so that the rotating shaft 4 does not produce axial displacement.

[0022] Above-mentioned torsion spring I5 is coated with sealant.

[0023] Above-mentioned nut 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com