Multi-pipeline steel ball falling test device

A test device and multi-pipe technology, which is applied in the direction of measuring device, impact test, machine/structural component test, etc., can solve the problem of not being able to meet the testing requirements of steel ball users, ignoring the shape and structure of steel ball test brackets and drop pipes, steel The ball affects the efficiency of the test, etc., to improve the quality, realize the split detection, and improve the efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

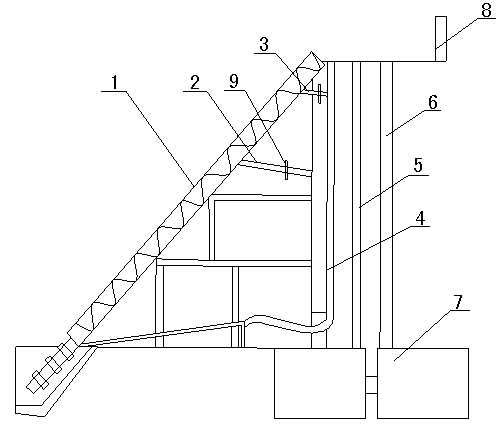

[0014] Such as figure 1 As shown, the multi-pipeline steel ball drop test device in the embodiment of the present invention includes a spiral elevator 1 and three falling straight pipes, and a rolling table is arranged on the top of the spiral elevator 1. Connecting with the top of the first falling straight pipe 4, a second falling straight pipe 5 and a third falling straight pipe 6 are added in sequence outside the first falling straight pipe 4, and these two straight pipes are respectively connected to the top of the screw hoist 1, Wherein the length of the second straight pipe 5 and the third straight pipe 6 is 3.5m and the diameter of the third straight pipe 6 is equal to twice the diameter of the first straight pipe 4 .

[0015] Between the first drop straight pipe 4 and the screw hoist 1 are provided with two rolling ball tracks, namely the second height rolling ball track 2 arranged in the middle and the first height rolling ball track 3 arranged at the top, located at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com