Double-tube steel ball free falling equipment

A technology of tube type and steel ball, which is applied in the field of double tube type steel ball free drop equipment, can solve the problem of ignoring the steel ball test bracket and the shape and structure of the drop pipe, failing to meet the testing requirements of the steel ball user, and the steel ball affecting the efficiency of the test and other issues to achieve the effect of improving quality, realizing split detection, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

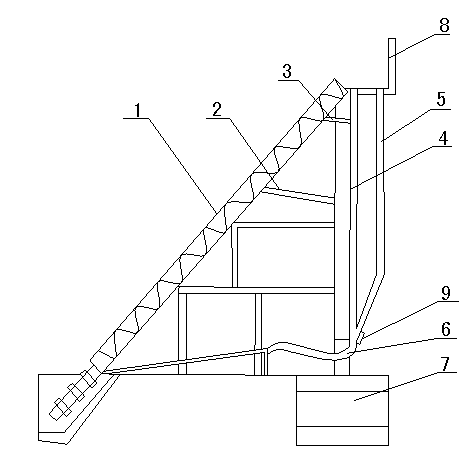

[0015] like figure 1 As shown, the double-tube steel ball free-falling equipment described in the embodiment of the present invention includes a spiral hoist 1 and a straight drop pipe 4. The spiral hoist 1 is arranged obliquely and its top is connected to the top of the straight drop pipe 4. A falling elbow 5 is installed on the outer side of the falling straight pipe 4, and the top of the falling elbow 5 is connected to the top of the screw hoist 1, and the lower part of the falling elbow 5 bends toward the side of the falling straight pipe 4; Two rolling ball tracks are arranged between the spiral elevators 1, that is, the second height rolling ball track 2 arranged in the middle and the first height rolling ball track 3 arranged at the top, which are respectively located in the falling straight pipe 4 and the falling curved pipe 5. The lower end of each is connected with the bottom slideway 6 respectively;

[0016] At the same time, the bottom end of the falling straight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com