Three-proofing and soil release textile fabric and preparation method thereof

A textile fabric, easy decontamination technology, used in textiles and papermaking, dry cleaning fiber products, fiber processing and other directions, can solve problems such as poor hand feel, low protection level, three-proof and easy decontamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

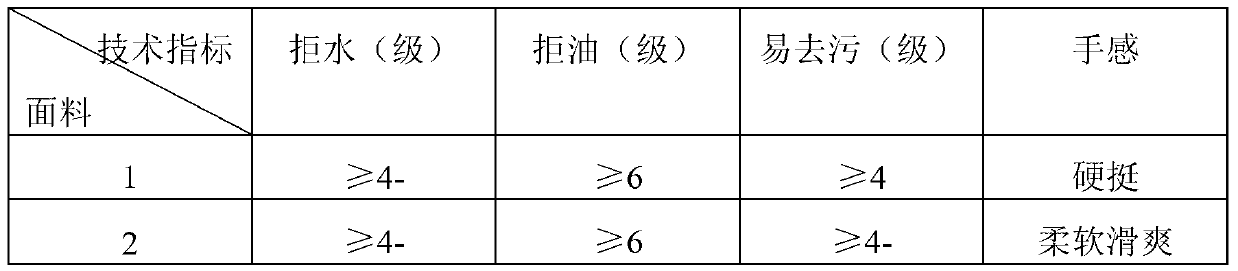

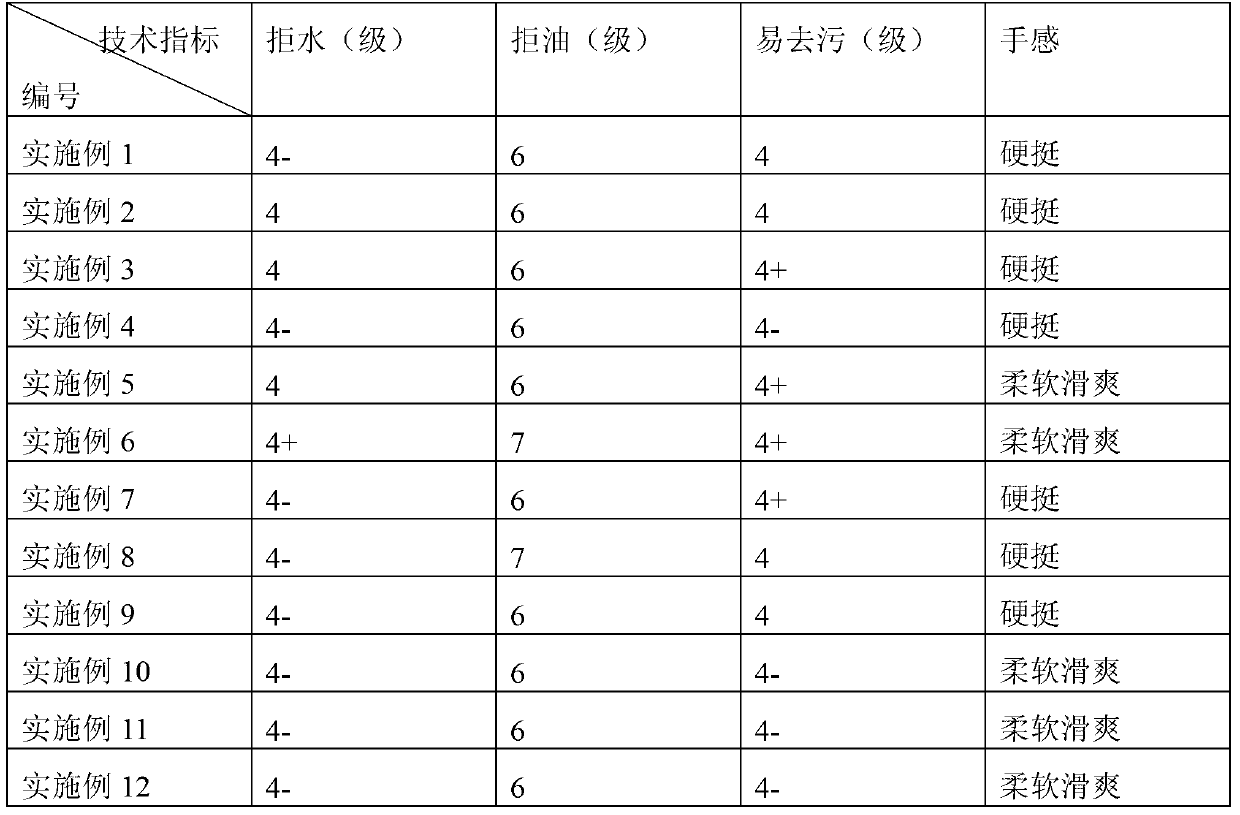

Examples

Embodiment 1

[0042] A preparation method of a three-proof and easy-to-decontaminate textile fabric. The base adopts a green fabric, and the prepared fabric has a super-hard feel. The preparation method includes the following steps:

[0043] Cleaning the green fabric step: Wash the polyester green fabric in the cleaning solution (ie the first aqueous solution) of the overflow dyeing machine for 30 minutes to remove the remaining oil stains, dirt and surfactants on the fabric surface. Among them, the temperature of the cleaning solution is controlled at about 70°C; the preparation of the cleaning solution is as follows: add detergent FK-9503 (purchased from Beijing Huafang High-tech Co., Ltd.) and fabric protectant FK-9500 (purchased from Beijing Huafang High-tech Co., Ltd.) and stir evenly so that the concentration of detergent FK-9503 in the cleaning solution is 3g / L, and the concentration of fabric protective agent FK-9500 in the cleaning solution is 2g / L. Then rinse with clean water 3 times...

Embodiment 2

[0048] A preparation method of a three-proof and easy-to-decontaminate textile fabric. The base adopts a green fabric, and the prepared fabric has a super-hard feel. The preparation method includes the following steps:

[0049] Cleaning the green fabric step: Wash the polyester-cotton green fabric in the cleaning solution (i.e. the first aqueous solution) in the overflow dyeing machine for 30 minutes to remove residual oil stains, taint and surfactants on the fabric surface. The temperature of the cleaning solution is controlled at about 80°C. The preparation of the cleaning solution is as follows: add detergent FK-9503 (purchased from Beijing Huafang High-tech Co., Ltd.) and fabric protectant FK-9500 (purchased from Beijing Huafang High-tech Co., Ltd.) and stir evenly so that the concentration of detergent FK-9503 in the cleaning solution is 2g / L, and the concentration of fabric protective agent FK-9500 in the cleaning solution is 4g / L. Then rinse with clean water 2 times, 10 mi...

Embodiment 3

[0054] A preparation method of a three-proof and easy-to-decontaminate textile fabric. The base adopts a green fabric, and the prepared fabric has a super-hard feel. The preparation method includes the following steps:

[0055] Cleaning the green fabric step: Wash the polyester-cotton green fabric in the cleaning solution (i.e. the first aqueous solution) in the overflow dyeing machine for 30 minutes to remove residual oil stains, taint and surfactants on the fabric surface. The temperature of the cleaning solution is controlled at about 80°C. The preparation of the cleaning solution is as follows: add detergent FK-9503 (purchased from Beijing Huafang High-tech Co., Ltd.) and fabric protectant FK-9500 (purchased from Beijing Huafang High-tech Co., Ltd.) and stir evenly so that the concentration of detergent FK-9503 in the cleaning solution is 2g / L, and the concentration of fabric protective agent FK-9500 in the cleaning solution is 4g / L. Then rinse with clean water 3 times, 10 mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com